Related Research Articles

The economy of Rwanda has undergone rapid industrialisation due to a successful governmental policy. It has a mixed economy. Since the early-2000s, Rwanda has witnessed an economic boom, which improved the living standards of many Rwandans. The Government's progressive visions have been the catalyst for the fast transforming economy. The President of Rwanda, Paul Kagame, has noted his ambition to make Rwanda the "Singapore of Africa".

Smelting is a process of applying heat and a chemical reducing agent to an ore to extract a desired base metal product. It is a form of extractive metallurgy that is used to obtain many metals such as iron, copper, silver, lead and zinc. Smelting uses heat and a chemical reducing agent to decompose the ore, driving off other elements as gases or slag and leaving the metal behind. The reducing agent is commonly a fossil fuel source of carbon, such as carbon monoxide from incomplete combustion of coke—or, in earlier times, of charcoal. The oxygen in the ore binds to carbon at high temperatures as the chemical potential energy of the bonds in carbon dioxide is lower than the bonds in the ore.

Coltan is a dull black metallic ore from which the elements niobium and tantalum are extracted. The niobium-dominant mineral in coltan is columbite, and the tantalum-dominant mineral is tantalite.

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite (Fe

3O

4, 72.4% Fe), hematite (Fe

2O

3, 69.9% Fe), goethite (FeO(OH), 62.9% Fe), limonite (FeO(OH)·n(H2O), 55% Fe) or siderite (FeCO3, 48.2% Fe).

Cassiterite is a tin oxide mineral, SnO2. It is generally opaque, but it is translucent in thin crystals. Its luster and multiple crystal faces produce a desirable gem. Cassiterite was the chief tin ore throughout ancient history and remains the most important source of tin today.

The tin mining industry on Dartmoor, Devon, England, is thought to have originated in pre-Roman times, and continued right through to the 20th century, when the last commercially worked mine closed in November 1930. From the 12th century onwards tin mining was regulated by a stannary parliament which had its own laws.

Scrap consists of recyclable materials, usually metals, left over from product manufacturing and consumption, such as parts of vehicles, building supplies, and surplus materials. Unlike waste, scrap has monetary value, especially recovered metals, and non-metallic materials are also recovered for recycling. Once collected, the materials are sorted into types — typically metal scrap will be crushed, shredded, and sorted using mechanical processes.

Minas da Panasqueira or Mina da Panasqueira is the generic name for a set of mining operations between Cabeço do Pião and the village of Panasqueira, which has operated in a technically integrated and continuous manner practically since the discovery of ore there. Subsequently, it was agglomerated into a single administrative entity called Couto Mineiro da Panasqueira which had its last demarcation on 9 March 1971 and later on in the present C-18 Mining Concession. The mining facilities are currently centralized in the area of Barroca Grande – Aldeia de São Francisco de Assis (Covilhã) through which the current underground operation, ore extraction and processing facilities are accessed.

Mount Isa Mines Limited ("MIM") operates the Mount Isa copper, lead, zinc and silver mines near Mount Isa, Queensland, Australia as part of the Glencore group of companies. For a brief period in 1980, MIM was Australia's largest company. It has pioneered several significant mining industry innovations, including the Isa Process copper refining technology, the Isasmelt smelting technology, and the IsaMill fine grinding technology, and it also commercialized the Jameson Cell column flotation technology.

Drakelands Mine, also known as Hemerdon Mine or Hemerdon Ball Mine, is a tungsten and tin mine. It is located 11 km northeast of Plymouth, near Plympton, in Devon, England. It lies to the north of the villages of Sparkwell and Hemerdon, and adjacent to the large china clay pits near Lee Moor. The mine had been out of operation since 1944, except for the brief operation of a trial mine in the 1980s. Work started to re-open it in 2014, but it ceased activities in 2018. It hosts the fourth largest tin-tungsten deposit in the world.

Bisie, divided into Mpama North and Mpama South deposits, is a tin deposit in the Walikale territory of the province of North Kivu in the Democratic Republic of the Congo (DRC). The mine was formerly an illegal source of an estimated 15,000 tons of tin, or 4% of global production. In early 2018 artisanal mining activity has stopped, and Alphamin Resources Corp., an exploration company, based in Mauritius, is leading an exploration of the site.

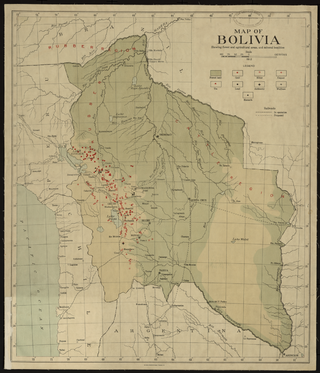

Mining in Bolivia has been a dominant feature of the Bolivian economy as well as Bolivian politics since 1557. Colonial era silver mining in Bolivia, particularly in Potosí, played a critical role in the Spanish Empire and the global economy. Tin mining supplanted silver by the twentieth century and the central element of Bolivian mining, and wealthy tin barons played an important role in national politics until they were marginalized by the industry's nationalization into the Bolivian Mining Corporation that followed the 1952 revolution. Bolivian miners played a critical part to the country's organized labor movement from the 1940s to the 1980s.

The Chillagoe smelters is a heritage-listed refinery at Chillagoe-Mungana Caves National Park, Mareeba Mining District, Chillagoe, Shire of Mareeba, Queensland, Australia. It operated in the early 1900s. It is also known as Chillagoe State Smelters. It was added to the Queensland Heritage Register on 21 October 1992.

Mining in Rwanda consists of extracting such minerals as tin, tantalum, and tungsten. In 2020, Rwanda earned about US$733m from mineral exports, making mining the biggest source of export revenues after tourism.

Tin mining began early in the Bronze Age, as bronze is a copper-tin alloy. Tin is a relatively rare element in the Earth's crust, with approximately 2 ppm, compared to iron with 50,000 ppm.

Mopani Copper Mines PLC is a Zambian company owned by ZCCM Investment Holdings.

The ISASMELT process is an energy-efficient smelting process that was jointly developed from the 1970s to the 1990s by Mount Isa Mines and the Government of Australia’s CSIRO. It has relatively low capital and operating costs for a smelting process.

OK Mine & Smelter is a heritage-listed mine at Kitoba Holding, Bellevue, Shire of Mareeba, Queensland, Australia. It was built from 1902 to 1942. It was added to the Queensland Heritage Register on 2 October 1996.

Irvinebank State Treatment Works is a heritage-listed refinery off Jessie Street, Irvinebank, Shire of Mareeba, Queensland, Australia. It was built from 1883 to c. 1908. It is also known as Loudoun Mill. It was added to the Queensland Heritage Register on 21 October 1992.

Almonty Industries is a global mining company focused on tungsten mining and exploration. Its primary operations are in Spain, Portugal, and South Korea. The company is listed on the Toronto Stock Exchange.

References

- ↑ "Phoenix Metal SARL". PANJIVA.

- ↑ "Rwanda reopens tin smelter". metalbulletin.

- ↑ "rwanda-mining-Rwanda Mining Revenue to Decline on Lower Tantalum Export Prices". bloomberg. 2014-05-23.

- ↑ "Rwanda Future Mining Hub of East Africa". GBR. 2014-06-05.

- ↑ "Govt Buys Phoenix-Metals for RWf1.2b". Rwanda Today. 2 June 2021.

- ↑ "Rwandan tin smelting firm certified as conflict free". The New Times. 2020-02-25.

- ↑ "Rwanda to resume smelting minerals for export". The East African. 2016-06-18.

- ↑ "Boost as Phoenix Metal resumes smelting tin". The East African. 2014-12-19.