Related Research Articles

Evaporation is a type of vaporization that occurs on the surface of a liquid as it changes into the gas phase. The surrounding gas must not be saturated with the evaporating substance. When the molecules of the liquid collide, they transfer energy to each other based on how they collide with each other. When a molecule near the surface absorbs enough energy to overcome the vapor pressure, it will escape and enter the surrounding air as a gas. When evaporation occurs, the energy removed from the vaporized liquid will reduce the temperature of the liquid, resulting in evaporative cooling.

Heat transfer is a discipline of thermal engineering that concerns the generation, use, conversion, and exchange of thermal energy (heat) between physical systems. Heat transfer is classified into various mechanisms, such as thermal conduction, thermal convection, thermal radiation, and transfer of energy by phase changes. Engineers also consider the transfer of mass of differing chemical species, either cold or hot, to achieve heat transfer. While these mechanisms have distinct characteristics, they often occur simultaneously in the same system.

A Stirling engine is a heat engine that is operated by the cyclic compression and expansion of air or other gas at different temperatures, resulting in a net conversion of heat energy to mechanical work. More specifically, the Stirling engine is a closed-cycle regenerative heat engine with a permanent gaseous working fluid. Closed-cycle, in this context, means a thermodynamic system in which the working fluid is permanently contained within the system, and regenerative describes the use of a specific type of internal heat exchanger and thermal store, known as the regenerator. Strictly speaking, the inclusion of the regenerator is what differentiates a Stirling engine from other closed-cycle hot air engines.

A thermostat is a regulating device component which senses the temperature of a physical system and performs actions so that the system's temperature is maintained near a desired setpoint.

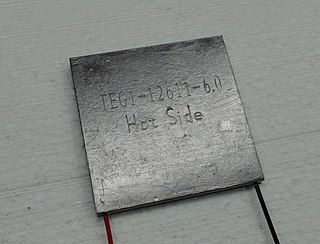

Thermoelectric cooling uses the Peltier effect to create a heat flux at the junction of two different types of materials. A Peltier cooler, heater, or thermoelectric heat pump is a solid-state active heat pump which transfers heat from one side of the device to the other, with consumption of electrical energy, depending on the direction of the current. Such an instrument is also called a Peltier device, Peltier heat pump, solid state refrigerator, or thermoelectric cooler (TEC) and occasionally a thermoelectric battery. It can be used either for heating or for cooling, although in practice the main application is cooling. It can also be used as a temperature controller that either heats or cools.

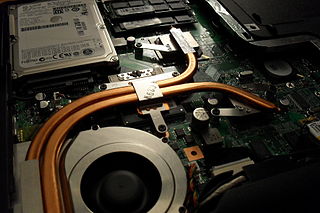

A heat pipe is a heat-transfer device that combines the principles of both thermal conductivity and phase transition to effectively transfer heat between two solid interfaces.

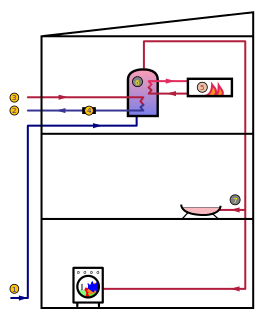

Water heating is a heat transfer process that uses an energy source to heat water above its initial temperature. Typical domestic uses of hot water include cooking, cleaning, bathing, and space heating. In industry, hot water and water heated to steam have many uses.

Internal combustion engine cooling uses either air or liquid to remove the waste heat from an internal combustion engine. For small or special purpose engines, cooling using air from the atmosphere makes for a lightweight and relatively simple system. Watercraft can use water directly from the surrounding environment to cool their engines. For water-cooled engines on aircraft and surface vehicles, waste heat is transferred from a closed loop of water pumped through the engine to the surrounding atmosphere by a radiator.

A chiller is a machine that removes heat from a liquid via a vapor-compression, adsorption refrigeration, or absorption refrigeration cycles. This liquid can then be circulated through a heat exchanger to cool equipment, or another process stream. As a necessary by-product, refrigeration creates waste heat that must be exhausted to ambience, or for greater efficiency, recovered for heating purposes. Vapor compression chillers may use any of a number of different types of compressors. Most common today are the hermetic scroll, semi-hermetic screw, or centrifugal compressors. The condensing side of the chiller can be either air or water cooled. Even when liquid cooled, the chiller is often cooled by an induced or forced draft cooling tower. Absorption and adsorption chillers require a heat source to function.

The vortex tube, also known as the Ranque-Hilsch vortex tube, is a mechanical device that separates a compressed gas into hot and cold streams. The gas emerging from the "hot" end can reach temperatures of 200 °C, and the gas emerging from the "cold end" can reach −50 °C (−58 °F). It has no moving parts.

Martin Hans Christian Knudsen was a Danish physicist who taught and conducted research at the Technical University of Denmark.

Regenerative cooling, in the context of rocket engine design, is a configuration in which some or all of the propellant is passed through tubes, channels, or in a jacket around the combustion chamber or nozzle to cool the engine. This is effective because the fuel are good coolants. The heated propellant is then fed into a special gas generator or injected directly into the main combustion chamber.

A circulator pump or circulating pump is a specific type of pump used to circulate gases, liquids, or slurries in a closed circuit. They are commonly found circulating water in a hydronic heating or cooling system. Because they only circulate liquid within a closed circuit, they only need to overcome the friction of a piping system.

An air source heat pump (ASHP) is a type of heat pump that absorbs heat from a colder place and release it into a warmer place using the same vapor-compression refrigeration process and same external heat exchanger with fan as used by an air conditioners. Unlike an air conditioning unit, however, it is able to both warm and cool building and in some cases also provide domestic hot water.

This article briefly describes the components and systems found in jet engines.

HVAC is a major subdiscipline of mechanical engineering. The goal of HVAC design is to balance indoor environmental comfort with other factors such as installation cost, ease of maintenance, and energy efficiency. The discipline of HVAC includes a large number of specialized terms and acronyms, many of which are summarized in this glossary.

TheVuilleumier cycle was patented by a Swiss-American engineer named Rudolph Vuilleumier in 1918. The purpose of Vuilleumier's machine was to create a heat pump that would use heat at high temperature as energy input. The Vuilleumier cycle...

utilize[s] working gas expansion and compression at three variable volume spaces in order to pump heat from a low to a moderate temperature level. The interesting characteristic of the Vuilleumier machine is that the induced volume variations are realized without the use of work, but thermally. This is the reason why it has a potential to operate at modern applications where the pollution of the environment is not a choice. It is a perfect candidate for such applications, as it consists only of metallic parts and inert gas. Using these units for heating and cooling buildings, large energy savings can be accomplished as they can be operated at small scale in common buildings or at large scale providing heat power to entire building blocks without using fossil fuels. The use of Vuilleumier machines for industrial applications or inside vehicles is also a feasible option. Another field where these machines have already been involved is cryogenics, as they are also able to provide refrigeration at very low temperatures like the very similar and well-known Stirling refrigerators.

Tankless water heaters—also called instantaneous, continuous flow, inline, flash, on-demand, or instant-on water heaters—are water heaters that instantly heat water as it flows through the device, and do not retain any water internally except for what is in the heat exchanger coil. Copper heat exchangers are preferred in these units because of their high thermal conductivity and ease of fabrication.

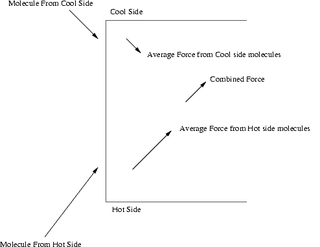

Thermal transpiration refers to the thermal force on a gas due to a temperature difference. Thermal transpiration causes a flow of gas in the absence of any pressure difference, and is able to maintain a certain pressure difference called thermomolecular pressure difference in a steady state. The effect is strongest when the mean free path of the gas molecules is comparable to the dimensions of the gas container.

The mechanism of diving regulators is the arrangement of components and function of gas pressure regulators used in the systems which supply breathing gases for underwater diving. Both free-flow and demand regulators use mechanical feedback of the downstream pressure to control the opening of a valve which controls gas flow from the upstream, high-pressure side, to the downstream, low-pressure side of each stage. Flow capacity must be sufficient to allow the downstream pressure to be maintained at maximum demand, and sensitivity must be appropriate to deliver maximum required flow rate with a small variation in downstream pressure, and for a large variation in supply pressure, without instability of flow. Open circuit scuba regulators must also deliver against a variable ambient pressure. They must be robust and reliable, as they are life-support equipment which must function in the relatively hostile seawater environment, and the human interface must be comfortable over periods of several hours.

References

- ↑ Gas pump made of minerals has no moving parts, PhysOrg.com

- ↑ Kataoa, Takeshi; Tsutahara, Michihisa; Ogawa, Kazuhiko; Yamamoto, Yoshifumi; Shoji, Masakazu; Sakai, Yoshihide (2004). "Knudsen Pump and Its Possibility of Application to Satellite Control". Theoretical and Applied Mechanics Japan. 53: 155–162. doi: 10.11345/nctam.53.155 .