Related Research Articles

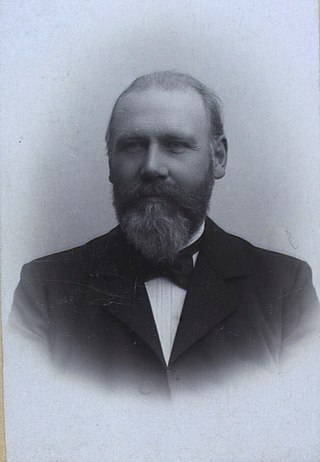

Henry Clifton Sorby was an English amateur microscopist and geologist. His major contribution was the development of techniques for thin sectioning of rocks and minerals with polarized light under a microscope which was also extended to study iron and steel, his family having being involved in the Sheffield iron and steel industry for generations. He also contributed to the study of meteorites by introducing a method of blowpipe analysis where molten beads were flattened for microscopic study. He was elected Fellow of the Royal Society in 1857.

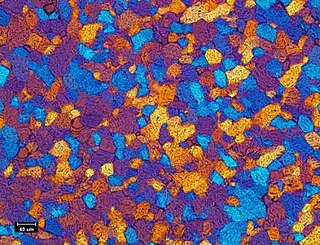

Metallography is the study of the physical structure and components of metals, by using microscopy.

George David William Smith FRS, FIMMM, FInstP, FRSC, CEng is a materials scientist with special interest in the study of the microstructure, composition and properties of engineering materials at the atomic level. He invented, together with Alfred Cerezo and Terry Godfrey, the Atom-Probe Tomograph in 1988.

David John Hugh Cockayne FRS FInstP was Professor in the physical examination of materials in the Department of Materials at the University of Oxford and professorial fellow at Linacre College from 2000 to 2009. He was the president of the International Federation of Societies for Microscopy from 2003 till 2007, then vice-president 2007 to 2010.

Joseph Irwin Goldstein was an American scientist and engineer, working mainly in the fields of materials science and mechanical engineering. He was a Professor of Mechanical Engineering and emeritus Dean of Engineering at the University of Massachusetts Amherst. His research into the nature of outer-space materials led to the naming of an asteroid after him in 2000, 4989 Joegoldstein.

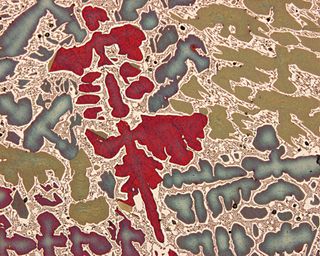

Ceramography is the art and science of preparation, examination and evaluation of ceramic microstructures. Ceramography can be thought of as the metallography of ceramics. The microstructure is the structure level of approximately 0.1 to 100 μm, between the minimum wavelength of visible light and the resolution limit of the naked eye. The microstructure includes most grains, secondary phases, grain boundaries, pores, micro-cracks and hardness microindentations. Most bulk mechanical, optical, thermal, electrical and magnetic properties are significantly affected by the microstructure. The fabrication method and process conditions are generally indicated by the microstructure. The root cause of many ceramic failures is evident in the microstructure. Ceramography is part of the broader field of materialography, which includes all the microscopic techniques of material analysis, such as metallography, petrography and plastography. Ceramography is usually reserved for high-performance ceramics for industrial applications, such as 85–99.9% alumina (Al2O3) in Fig. 1, zirconia (ZrO2), silicon carbide (SiC), silicon nitride (Si3N4), and ceramic-matrix composites. It is seldom used on whiteware ceramics such as sanitaryware, wall tiles and dishware.

The Microscopy Society of America (MSA) was founded in 1942 as The Electron Microscope Society of America and is a non-profit organization that provides microanalytical facilities for studies within the sciences. Currently, there are approximately 3000 members. The society holds an annual meeting, which is usually held in the beginning of August. It has 30 local affiliates across the United States. The society has a program for examining and certifying technologists of electron microscopes. The organization produces two journals: Microscopy Today, and Microscopy and Microanalysis. As of 2024, the President is Jay Potts.

Tanjore Ramachandra Anantharaman was one of India's pre-eminent metallurgists and materials scientists.

Nestor J. Zaluzec is an American scientist and inventor who works at the University of Chicago and Argonne National Laboratory. He invented and patented the Scanning Confocal Electron Microscope. and the π Steradian Transmission X-ray Detector for Electron-Optical Beam Lines and Microscopes.

Holger F. Struer was a Danish chemist and founder of "H. Struers Chemiske Laboratorium" in 1875 at Skindergade 38, the centre of Copenhagen. Struers introduced in 1943 Micropol, a new principle for electrolytic polishing which made the preparation process within metallography more controlled in order to achieve better preparation results.

Sir Harshad"Harry"Kumar Dharamshi Hansraj Bhadeshia is an Indian-British metallurgist and Emeritus Tata Steel Professor of Metallurgy at the University of Cambridge. In 2022 he joined Queen Mary University of London as Professor of Metallurgy.

Ivan Georgiev Petrov is a Bulgarian-American physicist specializing in thin films, surface science, and methods of characterization of materials. His research and scientific contributions have been described as having an "enormous impact on the hard-coatings community". Petrov was the president of the American Vacuum Society for 2015.

Frank Mücklich is a German materials scientist. He is professor at Saarland University and leads the Chair of Functional Materials.

John Wickham Steeds is a British physicist and materials scientist. He is an Emeritus Professor of Physics at the University of Bristol.

Peter Duncumb is a British physicist specialising in X-ray microscopy and microanalysis. He is best known for his contribution to the development of the first electron microprobe.

Neutron embrittlement, sometimes more broadly radiation embrittlement, is the embrittlement of various materials due to the action of neutrons. This is primarily seen in nuclear reactors, where the release of high-energy neutrons causes the long-term degradation of the reactor materials. The embrittlement is caused by the microscopic movement of atoms that are hit by the neutrons; this same action also gives rise to neutron-induced swelling causing materials to grow in size, and the Wigner effect causing energy buildup in certain materials that can lead to sudden releases of energy.

Dawn Austin Bonnell is the Senior Vice Provost for Research at the University of Pennsylvania. She has previously served as the Founding Director of the National Science Foundation Nano–Bio Interface Center, Vice President of the American Ceramic Society and President of the American Vacuum Society. In 2024, she was elected to the American Philosophical Society.

Rhonda M. Stroud is a materials physicist and planetary scientist at Arizona State University, where she serves as Director of the Buseck Center for Meteorite Studies. From 1998- 2022, she was a Research Physicist at the United States Naval Research Laboratory, where she led the Nanoscale Materials Section. She is known for her research on nanostructures, including quasicrystals and aerogel, and on the materials that make up comets and cosmic dust. She pioneered the use of focused ion beam technology in the study of meteorites.

Theresa Mary Vandecar Brassard was an American metallographer.

Lena Fitting Kourkoutis was an American physicist working in the field of electron microscopy, and a professor of applied and engineering physics at Cornell University. Her research focused on the use of aberration-corrected scanning transmission electron microscope, providing atomic resolution, at cryogenic temperatures (>77K) to study physical processes such as superconductivity and biological structures such as proteins.

References

- 1 2 3 4 5 Varano, Cameron (2020). "Grace Burke: Show Me the Data". Microscopy Today. 28 (6): 50–52. doi: 10.1017/S1551929520001510 . ISSN 1551-9295. S2CID 230653432.

- ↑ "MSE Colloquium: Grace Burke, Developing a Mechanistic Understanding of Irradiation Embrittlement of RPV Steels and Welds". Materials Science and Engineering. 2012-08-31. Retrieved 2022-03-14.

- ↑ "New Director for the Materials Performance Centre". The University of Manchester. Retrieved 2022-03-14.

- ↑ "President's Award of the MIcroAnalysis Society | Research Explorer | The University of Manchester". www.research.manchester.ac.uk. Retrieved 2022-03-14.

- ↑ "2018 M. Grace Burke". Microanalysis Society. 2018-11-16. Retrieved 2022-03-14.

- ↑ "Council". www.rms.org.uk. Retrieved 2022-03-14.

- ↑ "Henry Clifton Sorby Award | Research Explorer | The University of Manchester". www.research.manchester.ac.uk. Retrieved 2022-03-14.

- ↑ Labmate, International. "Prestigious Award Presented to RMS President Prof Grace Burke". Labmate Online. Retrieved 2022-03-14.

- ↑ "Henri Coriou Award Winners for outstanding contributions to corrosion science and engineering in the nuclear field" (PDF).