Related Research Articles

Hematite, also spelled as haematite, is a common iron oxide compound with the formula, Fe2O3 and is widely found in rocks and soils. Hematite crystals belong to the rhombohedral lattice system which is designated the alpha polymorph of Fe

2O

3. It has the same crystal structure as corundum (Al

2O

3) and ilmenite (FeTiO

3). With this it forms a complete solid solution at temperatures above 950 °C (1,740 °F).

Mining is the extraction of valuable geological materials and minerals from the surface of the Earth. Mining is required to obtain most materials that cannot be grown through agricultural processes, or feasibly created artificially in a laboratory or factory. Ores recovered by mining include metals, coal, oil shale, gemstones, limestone, chalk, dimension stone, rock salt, potash, gravel, and clay. The ore must be a rock or mineral that contains valuable constituent, can be extracted or mined and sold for profit. Mining in a wider sense includes extraction of any non-renewable resource such as petroleum, natural gas, or even water.

A slurry pipeline is a specially engineered pipeline used to move ores, such as coal or iron, or mining waste, called tailings, over long distances. A mixture of the ore concentrate and water, called slurry, is pumped to its destination and the water is filtered out. Due to the abrasive properties of slurry, the pipelines can be lined with high-density polyethylene (HDPE), or manufactured completely from HDPE Pipe, although this requires a very thick pipe wall. Slurry pipelines are used as an alternative to railroad transportation when mines are located in remote, inaccessible areas.

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite (Fe

3O

4, 72.4% Fe), hematite (Fe

2O

3, 69.9% Fe), goethite (FeO(OH), 62.9% Fe), limonite (FeO(OH)·n(H2O), 55% Fe), or siderite (FeCO3, 48.2% Fe).

Ilmenite is a titanium-iron oxide mineral with the idealized formula FeTiO

3. It is a weakly magnetic black or steel-gray solid. Ilmenite is the most important ore of titanium and the main source of titanium dioxide, which is used in paints, printing inks, fabrics, plastics, paper, sunscreen, food and cosmetics.

The Mesabi Iron Range is a mining district and mountain range in northeastern Minnesota following an elongate trend containing large deposits of iron ore. It is the largest of four major iron ranges in the region collectively known as the Iron Range of Minnesota. First described in 1866, it is the chief iron ore mining district in the United States. The district is located largely in Itasca and Saint Louis counties. It has been extensively worked since 1892, and has seen a transition from high-grade direct shipping ores through gravity concentrates to the current industry exclusively producing iron ore (taconite) pellets. Production has been dominantly controlled by vertically integrated steelmakers since 1901, and therefore is dictated largely by US ironmaking capacity and demand.

Gold cyanidation is a hydrometallurgical technique for extracting gold from low-grade ore by converting the gold to a water-soluble coordination complex. It is the most commonly used leaching process for gold extraction. Cyanidation is also widely used in the extraction of silver, usually after froth flotation.

Taconite is a variety of banded iron formation, an iron-bearing sedimentary rock, in which the iron minerals are interlayered with quartz, chert, or carbonate. The name taconyte was coined by Horace Vaughn Winchell (1865–1923) – son of Newton Horace Winchell, the Minnesota state geologist – during their pioneering investigations of the Precambrian Biwabik Iron Formation of northeastern Minnesota. He believed the sedimentary rock sequence hosting the iron-formation was correlative with the Taconic orogeny of New England, and referred to the unfamiliar and as-yet-unnamed iron-bearing rock as the 'taconic rock' or taconyte.

In mining, tailings or tails are the materials left over after the process of separating the valuable fraction from the uneconomic fraction (gangue) of an ore. Tailings are different from overburden, which is the waste rock or other material that overlies an ore or mineral body and is displaced during mining without being processed.

Zouérat is the largest town in northern Mauritania and the capital of the Tiris Zemmour region, with an approximate population of 62,380 (2023). It lies at the eastern end of the Mauritania Railway to Nouadhibou.

In mining, gangue is the commercially worthless material that surrounds, or is closely mixed with, a wanted mineral in an ore deposit. It is thus distinct from overburden, which is the waste rock or materials overlying an ore or mineral body that are displaced during mining without being processed, and from tailings, which is rock already stripped of valuable minerals.

Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling.

The Vermilion Range exists between Tower, Minnesota and Ely, Minnesota, and contains significant deposits of iron ore. Together with the Mesabi, Gunflint, and Cuyuna ranges, these four constitute the Iron Ranges of northern Minnesota. While the Mesabi Range had iron ore close enough to the surface to enable pit mining, mines had to be dug deep underground to reach the ore of the Vermilion and Cuyuna ranges. The Soudan mine was nearly 1/2 mile underground and required blasting of Precambrian sedimentary bedrock.

El Cerro Mutún (Spanish for "the Mountain Mutún") is an iron ore deposit. Located in the Germán Busch Province in the Santa Cruz Department of Bolivia, near Puerto Suárez, it extends across the border into Brazil, where it is called the Serrania de Jacadigo. Also known as the "Serrania Mutún", it has an area of about 75 square kilometers. Its estimated reserves are about 40.205 billion (40.205 × 109) tons of iron ore of 50% iron, mainly in hematite and magnetite form, and in lesser quantities in siderite and manganese minerals. This can be compared with an estimate of the total world reserves of iron ore: 800 billion tons of crude ore containing more than 230 billion tons of iron.

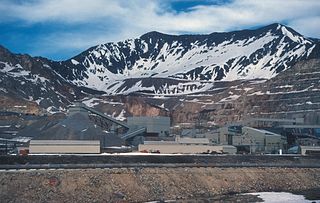

The Climax mine, located in Climax, Colorado, United States, is a major molybdenum mine in Lake and Summit counties, Colorado. Shipments from the mine began in 1915. At its highest output, the Climax mine was the largest molybdenum mine in the world, and for many years it supplied three quarters of the world's supply of molybdenum.

The Buena Vista Mine is located 21 miles (34 km) southeast of Lovelock, Nevada. In the past, the area has been known as the Mineral Basin, though another name for the area has been the Buena Vista District. There are at least two other Buena Vista Mining Districts in Nevada; one is located near Unionville, Nevada, and the other is located in Esmeralda and Mineral counties near the California border. The nearby Buena Vista Hills are named for the mine. The district encompasses roughly 21 square miles (54 km2) of mineral and surface rights, and is one of the largest un-mined iron ore resources in the western United States.

Mining in North Korea is important to the country's economy. North Korea is naturally abundant in metals such as magnesite, zinc, tungsten, and iron; with magnesite resources of 6 billion tonnes, particularly in the North and South Hamgyong Provinces, as well as the Chagang Province. However, often these cannot be mined due to the acute shortage of electricity in the country, as well as the lack of proper tools to mine these materials and an antiquated industrial base. Coal, iron ore, limestone, and magnesite deposits are larger than other mineral commodities. Mining joint ventures have occurred with other countries include China, Canada, Egypt, and South Korea.

The Middleback Range is a mountain range on the eastern side of Eyre Peninsula in South Australia. The Middleback Range has been a source of iron ore for over a century, particularly to feed the Whyalla Steelworks. Mines in the region were first developed by BHP from the 1890s and are now owned and operated by Liberty House Group.

The environmental impact of iron ore mining in all its phases from excavation to beneficiation to transportation and beyond may have detrimental effects on air quality, water quality, biological species, and nearby communities. This is predominantly a result of large-scale iron ore tailings that are released into the environment which are harmful to both animals and humans.

The Société du Djebel-Djérissa (SDD) is a Tunisian iron ore mining company founded in 1899 that began operations in 1907. It produced up to 700,000 tons per year of hematite ore in the years before World War II. Production dropped during the war. The company was nationalized in 1961. Today levels of output are around 200,000 tons annually.

References

- ↑ "The Next Iron Rush". Fortune . May 25, 2009, pp. 86-90.

- ↑ "Former Magnetation boss set to buy back plant, property of bankrupt mining company". Duluth News Tribune. 2021-12-15. Retrieved 2024-12-10.