Spinning is a twisting technique to form yarn from fibers. The fiber intended is drawn out, twisted, and wound onto a bobbin. A few popular fibers that are spun into yarn other than cotton, which is the most popular, are viscose, animal fibers such as wool, and synthetic polyester. Originally done by hand using a spindle whorl, starting in the 500s AD the spinning wheel became the predominant spinning tool across Asia and Europe. The spinning jenny and spinning mule, invented in the late 1700s, made mechanical spinning far more efficient than spinning by hand, and especially made cotton manufacturing one of the most important industries of the Industrial Revolution.

In textile production, carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with "card clothing", a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing.

John Kay was an English inventor whose most important creation was the flying shuttle, which was a key contribution to the Industrial Revolution. He is often confused with his namesake, who built the first "spinning frame".

A cotton mill is a building that houses spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

Edward Cave was an English printer, editor and publisher. He coined the term "magazine" for a periodical, founding The Gentleman's Magazine in 1731, and was the first publisher to successfully fashion a wide-ranging publication.

Textile manufacture during the British Industrial Revolution was centred in south Lancashire and the towns on both sides of the Pennines in the United Kingdom. The main drivers of the Industrial Revolution were textile manufacturing, iron founding, steam power, oil drilling, the discovery of electricity and its many industrial applications, the telegraph and many others. Railroads, steamboats, the telegraph and other innovations massively increased worker productivity and raised standards of living by greatly reducing time spent during travel, transportation and communications.

The spinning mule is a machine used to spin cotton and other fibres. They were used extensively from the late 18th to the early 20th century in the mills of Lancashire and elsewhere. Mules were worked in pairs by a minder, with the help of two boys: the little piecer and the big or side piecer. The carriage carried up to 1,320 spindles and could be 150 feet (46 m) long, and would move forward and back a distance of 5 feet (1.5 m) four times a minute.

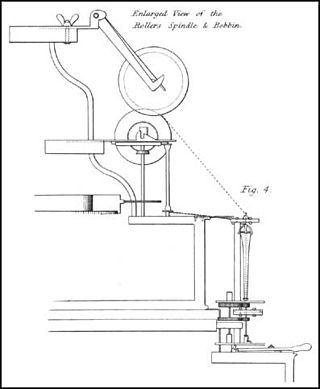

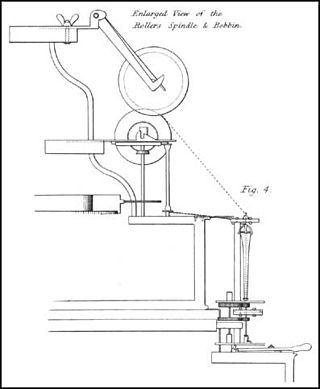

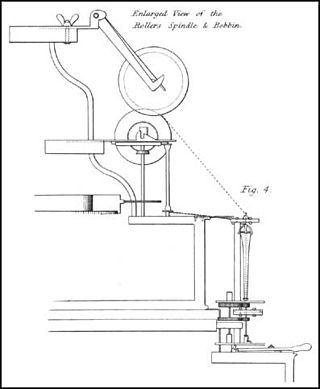

Cotton-spinning machinery is machines which process prepared cotton roving into workable yarn or thread. Such machinery can be dated back centuries. During the 18th and 19th centuries, as part of the Industrial Revolution cotton-spinning machinery was developed to bring mass production to the cotton industry. Cotton spinning machinery was installed in large factories, commonly known as cotton mills.

Thomas Highs (1718–1803), of Leigh, Lancashire, was a reed-maker and manufacturer of cotton carding and spinning engines in the 1780s, during the Industrial Revolution. He is known for claiming patents on a spinning jenny, a carding machine and the throstle.

John Wyatt, an English inventor, was born near Lichfield and was related to Sarah Ford, Doctor Johnson's mother. A carpenter by trade he began work in Birmingham on the development of a spinning machine. In 1733 he was working in the mill at New Forge (Powells) Pool, Sutton Coldfield attempting to spin the first cotton thread ever spun by mechanical means.

Lewis Paul was the original inventor of roller spinning, the basis of the water frame for spinning cotton in a cotton mill.

Thomas Warren was an English bookseller, printer, publisher and businessman.

Ring spinning is a spindle-based method of spinning fibres, such as cotton, flax or wool, to make a yarn. The ring frame developed from the throstle frame, which in its turn was a descendant of Arkwright's water frame. Ring spinning is a continuous process, unlike mule spinning which uses an intermittent action. In ring spinning, the roving is first attenuated by using drawing rollers, then spun and wound around a rotating spindle which in its turn is contained within an independently rotating ring flyer. Traditionally ring frames could only be used for the coarser counts, but they could be attended by semi-skilled labour.

Scutching is a step in the processing of cotton or the dressing of flax or hemp in preparation for spinning. The scutching process separates the impurities from the raw material, such as the seeds from raw cotton or the straw and woody stem from flax fibers. Scutching can be done by hand or by a machine known as a scutcher. Hand scutching of flax is done with a wooden scutching knife and a small iron scraper. The end products of scutching flax are the long finer flax fibers called line, short coarser fibers called tow, and waste woody matter called shives.

The Upper Priory Cotton Mill, opened in Birmingham, England in the summer of 1741, was the world's first mechanised cotton-spinning factory or cotton mill. Established by Lewis Paul and John Wyatt in a former warehouse in the Upper Priory, near Paul's house in Old Square, it was the first of the Paul-Wyatt cotton mills that used the roller spinning machinery that they had developed and that had been patented by Paul in 1738, that for the first time enabled the spinning of cotton "without the aid of human fingers". Wyatt had realised that this machinery would enable several machines to be powered from a single source of power: foreseeing the development of the factory system, he envisaged "a kind of mill, with wheels turned either by horses, water or wind."

Daniel Bourn was an English inventor, who took out a patent for a carding machine with rotating cylinders in 1748.

Robert "Parsley" Peel was a British merchant who was the grandfather of Robert Peel, a future prime minister of the United Kingdom. Peel started life as a yeoman farmer but experimented with calico printing, eventually creating a parsley leaf pattern which would become his trademark. Despite losing a number of machines during riots, Peel's company became the largest in the textile sector by the time of his death, with 23 factories.

The Paul-Wyatt cotton mills were the world's first mechanised cotton spinning factories. Operating from 1741 until 1764 they were built to house the roller spinning machinery invented by Lewis Paul and John Wyatt. They were not very profitable but they spun cotton successfully for several decades.

Pinsley Mill, also known as Etnam Street Mill, is a former watermill in Leominster, Herefordshire, England.

Samuel Touchet was an English cotton merchant, manufacturer and politician.