In telecommunication, electronics and the electrical power industry, the term demand factor is used to refer to the fractional amount of some quantity being used relative to the maximum amount that could be used by the same system. The demand factor is always less than or equal to one. As the amount of demand is a time dependent quantity so is the demand factor.

Load or LOAD may refer to:

In electrical engineering, the power factor of an AC power system is defined as the ratio of the real power absorbed by the load to the apparent power flowing in the circuit. Real power is the instantaneous product of voltage and current and represents the capacity of the electricity for performing work. Apparent power is the product of RMS current and voltage. Due to energy stored in the load and returned to the source, or due to a non-linear load that distorts the wave shape of the current drawn from the source, the apparent power may be greater than the real power, so more current flows in the circuit than would be required to transfer real power alone. A power factor magnitude of less than one indicates the voltage and current are not in phase, reducing the average product of the two. A negative power factor occurs when the device generates power, which then flows back towards the source.

The kilowatt-hour is a unit of energy equal to one kilowatt of power sustained for one hour and is commonly used as a measure of electrical energy.

Electronic test equipment is used to create signals and capture responses from electronic devices under test (DUTs). In this way, the proper operation of the DUT can be proven or faults in the device can be traced. Use of electronic test equipment is essential to any serious work on electronics systems.

The output impedance of an electrical network is the measure of the opposition to current flow (impedance), both static (resistance) and dynamic (reactance), into the load network being connected that is internal to the electrical source. The output impedance is a measure of the source's propensity to drop in voltage when the load draws current, the source network being the portion of the network that transmits and the load network being the portion of the network that consumes.

An electricity meter, electric meter, electrical meter, energy meter, or kilowatt-hour meter is a device that measures the amount of electric energy consumed by a residence, a business, or an electrically powered device.

In various contexts of science, technology, and manufacturing, an indicator is any of various instruments used to accurately measure small distances and angles, and amplify them to make them more obvious. The name comes from the concept of indicating to the user that which their naked eye cannot discern; such as the presence, or exact quantity, of some small distance.

The wattmeter is an instrument for measuring the electric active power in watts of any given circuit. Electromagnetic wattmeters are used for measurement of utility frequency and audio frequency power; other types are required for radio frequency measurements.

A load cell is a force transducer. It converts a force such as tension, compression, pressure, or torque into an electrical signal that can be measured and standardized. As the force applied to the load cell increases, the electrical signal changes proportionally. The most common types of load cell used are strain gauges, pneumatic, and hydraulic.

Maximum power point tracking (MPPT) or sometimes just power point tracking (PPT), is a technique used with variable power sources to maximize energy extraction as conditions vary. The technique is most commonly used with photovoltaic (PV) solar systems, but can also be used with wind turbines, optical power transmission and thermophotovoltaics.

In electrical and electronic engineering, a current clamp, also known as current probe, is an electrical device with jaws which open to allow clamping around an electrical conductor. This allows measurement of the current in a conductor without the need to make physical contact with it, or to disconnect it for insertion through the probe.

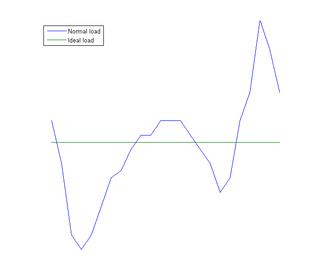

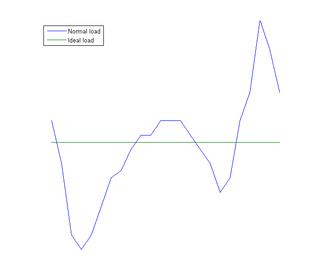

In electrical engineering, a load profile is a graph of the variation in the electrical load versus time. A load profile will vary according to customer type, temperature and holiday seasons. Power producers use this information to plan how much electricity they will need to make available at any given time. Teletraffic engineering uses a similar load curve.

Standby power, also called vampire power, vampire draw, phantom load, ghost load or leaking electricity, refers to the way electric power is consumed by electronic and electrical appliances while they are switched off or in standby mode. This only occurs because some devices claimed to be "switched off" on the electronic interface, but are in a different state from switching off at the plug, or disconnecting from the power point, which can solve the problem of standby power completely. In fact, switching off at the power point is effective enough, there is no need to disconnect all devices from the power point. Some such devices offer remote controls and digital clock features to the user, while other devices, such as power adapters for disconnected electronic devices, consume power without offering any features. All of the above examples, such as the remote control, digital clock functions and—in the case of adapters, no-load power—are switched off just by switching off at the power point. However, for some devices with built-in internal battery, such as a phone, the standby functions can be stopped by removing the battery instead.

Dynamic Demand is the name of a semi-passive technology to support demand response by adjusting the load demand on an electrical power grid. The concept is that by monitoring the frequency of the power grid, as well as their own controls, intermittent domestic and industrial loads switch themselves on/off at optimal moments to balance the overall grid load with generation, reducing critical power mismatches. As this switching would only advance or delay the appliance operating cycle by a few seconds, it would be unnoticeable to the end user. This is the foundation of dynamic demand control. In the United States, in 1982, a (now-lapsed) patent for this idea was issued to power systems engineer Fred Schweppe. Other patents have been issued based on this idea.

Load balancing, load matching, or daily peak demand reserve refers to the use of various techniques by electrical power stations to store excess electrical power during low demand periods for release as demand rises. The aim is for the power supply system to have a load factor of 1.

Load management, also known as demand-side management (DSM), is the process of balancing the supply of electricity on the network with the electrical load by adjusting or controlling the load rather than the power station output. This can be achieved by direct intervention of the utility in real time, by the use of frequency sensitive relays triggering the circuit breakers, by time clocks, or by using special tariffs to influence consumer behavior. Load management allows utilities to reduce demand for electricity during peak usage times, which can, in turn, reduce costs by eliminating the need for peaking power plants. In addition, some peaking power plants can take more than an hour to bring on-line which makes load management even more critical should a plant go off-line unexpectedly for example. Load management can also help reduce harmful emissions, since peaking plants or backup generators are often dirtier and less efficient than base load power plants. New load-management technologies are constantly under development — both by private industry and public entities.

In electrical engineering the load factor is defined as the average load divided by the peak load in a specified time period. It is a measure of the utilization rate, or efficiency of electrical energy usage; a high load factor indicates that load is using the electric system more efficiently, whereas consumers or generators that underutilize the electric distribution will have a low load factor.

A measuring instrument is a device to measure a physical quantity. In the physical sciences, quality assurance, and engineering, measurement is the activity of obtaining and comparing physical quantities of real-world objects and events. Established standard objects and events are used as units, and the process of measurement gives a number relating the item under study and the referenced unit of measurement. Measuring instruments, and formal test methods which define the instrument's use, are the means by which these relations of numbers are obtained. All measuring instruments are subject to varying degrees of instrument error and measurement uncertainty. These instruments may range from simple objects such as rulers and stopwatches to electron microscopes and particle accelerators. Virtual instrumentation is widely used in the development of modern measuring instruments.

This glossary of electrical and electronics engineering is a list of definitions of terms and concepts related specifically to electrical engineering and electronics engineering. For terms related to engineering in general, see Glossary of engineering.