Paint is a liquid pigment that, after application to a solid material, and allowed to dry, adds a film-like layer to protect, add color, or provide texture. Paint can be made in many colors—and in many different types. Most paints are either oil-based or water-based, and each has distinct characteristics.

A label is a piece of paper, plastic film, cloth, metal, or other material affixed to a container or product, on which is written or printed information or symbols about the product or item. Information printed directly on a container or article can also be considered labelling.

A paper bag is a bag made of paper, usually kraft paper. Paper bags can be made either with virgin or recycled fibres to meet customers’ demands. Paper bags are commonly used as shopping carrier bags and for packaging of some consumer goods. They carry a wide range of products from groceries, glass bottles, clothing, books, toiletries, electronics and various other goods and can also function as means of transport in day-to-day activities.

Municipal solid waste (MSW), commonly known as trash or garbage in the United States and rubbish in Britain, is a waste type consisting of everyday items that are discarded by the public. "Garbage" can also refer specifically to food waste, as in a garbage disposal; the two are sometimes collected separately. In the European Union, the semantic definition is 'mixed municipal waste,' given waste code 20 03 01 in the European Waste Catalog. Although the waste may originate from a number of sources that has nothing to do with a municipality, the traditional role of municipalities in collecting and managing these kinds of waste have produced the particular etymology 'municipal.'

Glass recycling is the processing of waste glass into usable products. Glass that is crushed or imploded and ready to be remelted is called cullet. There are two types of cullet: internal and external. Internal cullet is composed of defective products detected and rejected by a quality control process during the industrial process of glass manufacturing, transition phases of product changes and production offcuts. External cullet is waste glass that has been collected or reprocessed with the purpose of recycling. External cullet is classified as waste. The word "cullet", when used in the context of end-of-waste, will always refer to external cullet.

Waste Management, Inc., doing business as WM, is a waste management, comprehensive waste, and environmental services company operating in North America. Founded in 1968, the company is headquartered in the Bank of America Tower in Houston, Texas.

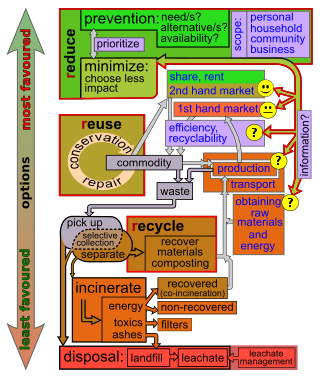

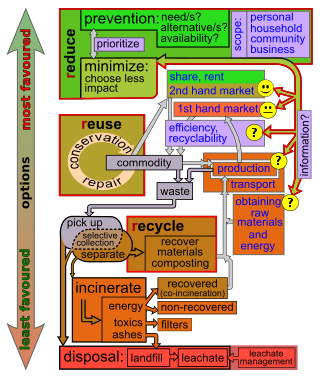

Waste minimisation is a set of processes and practices intended to reduce the amount of waste produced. By reducing or eliminating the generation of harmful and persistent wastes, waste minimisation supports efforts to promote a more sustainable society. Waste minimisation involves redesigning products and processes and/or changing societal patterns of consumption and production.

The Green Project is a not-for-profit environmental organization established in 1994 in St. Roch, New Orleans, Louisiana. The Green Project began as a salvage operation to recover unwanted paint then expanded to used building materials in 1996. In the past, the project participated in the deconstruction of New Orleans's homes and buildings but has since focused only on donations. The project operates a retail outlet, and community workshops. Materials accepted include:

Biodegradable plastics are plastics that can be decomposed by the action of living organisms, usually microbes, into water, carbon dioxide, and biomass. Biodegradable plastics are commonly produced with renewable raw materials, micro-organisms, petrochemicals, or combinations of all three.

Rates of household recycling in Ireland have increased dramatically since the late 1990s. The Irish Environmental Protection Agency (EPA) is the agency with overall responsibility for environmental protection in Ireland and monitors rates of recycling in Ireland along with other measures of environmental conditions in Ireland. The EPA, along with Repak, the principal organisation for packaging recycling in Ireland, report on recycling rates each year. In 2012 Ireland’s municipal solid waste (MSW) recycling rate was 34%, while the rate of packaging recycling reached 79%. The amount of municipal waste generated per person per year in Ireland has fallen significantly in recent years. This figure remains above the European Union annual municipal waste average of 503 kg per person, however. Each local council in Ireland has considerable control over recycling, so recycling practices vary to some extent across the country. Most waste that is not recycled is disposed of in landfill sites.

Toronto Solid Waste Management Services is the municipal service that handles the transfer and disposal of garbage as well as the processing and sale of recyclable materials collected through the blue box program in Toronto, Ontario, Canada.

Paint is a recyclable item. Latex paint is collected at collection facilities in many countries and shipped to paint-recycling facilities.

The environmental effects of paint can vary depending on the type of paint used and mitigation measures. Traditional painting materials and processes can have harmful effects on the environment, including those from the use of lead and other additives. Measures can be taken to reduce its environmental effects, including accurately estimating paint quantities so waste is minimized, and use of environmentally preferred paints, coating, painting accessories, and techniques.

Biodegradable bags are bags that are capable of being decomposed by bacteria or other living organisms.

Sustainable furniture design and sustainable interior design is the design of a habitable interior using furniture, finishes, and equipment while addressing the environmental impact of products and building materials used. By considering the life-cycle impact of each step, from raw material through the manufacturing process and through the product's end of life, sustainable choices can be made. Design considerations can include using recycled materials in the manufacturing process, reutilizing found furniture and using products that can be disassembled and recycled or reclaimed after their useful life. Another method of approach is working with local materials and vendors as a source for raw materials or products. Sustainable furniture design strives to create a closed-loop cycle in which materials and products are perpetually recycled so as to avoid disposal in landfills.

GreenBottle Ltd was the manufacturer of sustainable, paper-based liquids packaging. In 2017, Ecologic Brands Inc.,based in Manteca California, purchased the assets of the former GreenBottle.

Austin ReBlend is a paint recycling program administered by the City of Austin in Austin, Texas. In 2012, Austin ReBlend produced 12,767 US gal (48,330 L) of wholly recycled paint.

Fireclay Tile is a North American architectural tile company. Founded in 1986 by Paul Burns, Jeff Alvord, Martin Zepeda, and Albert Batista. Fireclay is known for designing and hand-making tile in Northern California, while actively incorporating environmentally sustainable practices.

Miranda Wang, is the cofounder of Novoloop, which is a company that aims to turn plastic waste into high-performance materials that can be used in a variety of products. Novoloop's process has the potential to greatly reduce the amount of plastic that enters landfills every year, as well as the amount of CO2 that is emitted by commonly used methods of material production.

Closed Loop Box Reuse, is the process by which boxes or other containers are reused many times. It is a form of reusable packaging.