Beeston is a town in the Borough of Broxtowe, Nottinghamshire, England, it is 3 miles south-west of Nottingham. To its north-east is the University of Nottingham's main campus, University Park. The headquarters of pharmaceutical and retail chemist group Boots are 0.6 miles (1 km) east of the centre of Beeston, on the border with Broxtowe and the City of Nottingham. To the south lie the River Trent and the village of Attenborough, with extensive wetlands.

A machinist is a tradesperson or trained professional who operates machine tools, and has the ability to set up tools such as milling machines, grinders, lathes, and drilling machines.

Marcos Engineering was a British sports car manufacturer. The name derives from the surnames of founders Jem Marsh and Frank Costin.

Humber Limited was a British manufacturer of bicycles, motorcycles, and cars, incorporated and listed on the stock exchange in 1887. It took the name "Humber & Co Limited" because of the high reputation of the products of one of the constituent businesses that had belonged to Thomas Humber. A financial reconstruction in 1899 transferred its business to Humber Limited.

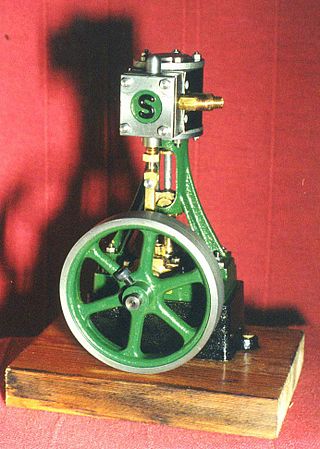

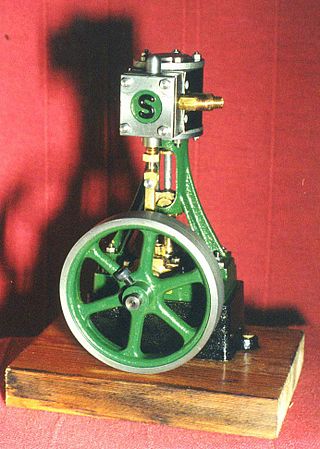

Model engineering is the pursuit of constructing proportionally-scaled miniature working representations of full-sized machines. It is a branch of metalworking with a strong emphasis on artisanry, as opposed to mass production. While now mainly a hobby, in the past it also had commercial and industrial purpose. The term 'model engineering' was in use by 1888. In the United States, the term 'home shop machinist' is often used instead, although arguably the scope of this term is broader.

FANUC is a Japanese group of companies that provide automation products and services such as robotics and computer numerical control wireless systems. These companies are principally FANUC Corporation of Japan, Fanuc America Corporation of Rochester Hills, Michigan, USA, and FANUC Europe Corporation S.A. of Luxembourg.

A turret lathe is a form of metalworking lathe that is used for repetitive production of duplicate parts, which by the nature of their cutting process are usually interchangeable. It evolved from earlier lathes with the addition of the turret, which is an indexable toolholder that allows multiple cutting operations to be performed, each with a different cutting tool, in easy, rapid succession, with no need for the operator to perform set-up tasks in between or to control the toolpath. The latter is due to the toolpath's being controlled by the machine, either in jig-like fashion, via the mechanical limits placed on it by the turret's slide and stops, or via digitally-directed servomechanisms for computer numerical control lathes.

New Imperial was a British motorcycle manufacturer founded by Norman Downes in Birmingham, between 1887 and 1901, and became New Imperial Motors Ltd in 1912, when serious production commenced. New Imperial made innovative motorcycles that employed unit construction and sprung heel frames long before they became commonplace, and were moderately successful in competition. The 1920s were a financially successful decade, enabling the innovations of the 1930s that fought decline.

Platt Brothers, also known as Platt Bros & Co Ltd, was a British company based at Werneth in Oldham, North West England. The company manufactured textile machinery and were iron founders and colliery proprietors. By the end of the 19th century, the company had become the largest textile machinery manufacturer in the world, employing more than 12,000 workers.

Bridgeport Machines, Inc., is a machine tool builder founded in 1938 in the United States of America. It manufactures Milling machines and Lathes.

Delcam is a supplier of advanced CAD/CAM software for the manufacturing industry. The company has grown steadily since being founded formally in 1977, after initial development work at Cambridge University, UK. It is now a global developer of product design and manufacturing software, with subsidiaries and joint ventures in North America, South America, Europe and Asia with a total staff of over 800 people and local support provided from over 300 re-seller offices worldwide. It was listed on the London Stock Exchange until 6 February 2014, when it was acquired by Autodesk. It now operates as a wholly owned, independently operated subsidiary of Autodesk.

MÁG stands for "Magyar Általános Gépgyár Rt". It was the most prevalent Hungarian vehicle manufacturer before World War II, and was based in Budapest. Its roots date back to 1901, when Podvinecz & Heisler, started assembling Austrian Leesdorfer cars - themselves being French Amédée Bollée cars built under license.

Markham & Co. was an ironworks and steelworks company near Chesterfield, Derbyshire, England.

Boxford Lathe was a brand of lathes produced by Denford Machine Tools from 1946 until 1952. The original factory was in Box Tree Mills, Wheatley, Halifax, West Yorkshire, England. Denford Machine Tools also produced other metalworking tools including precision measuring tools such as an optical comparator. The lathes and other tools were marketed under the name "Box-Ford". The name appears to be a portmanteau of "Box Tree Mills" and the founder's surname, "Denford". In 1952, the founder, Horace Denford, sold the company with Boxfords continuing at Halifax and Denfords in Brighouse.

Okuma Corporation is a machine tool builder based in Ōguchi, Aichi Prefecture, Japan. It has global market share in CNC machine tools such as CNC lathes, machining centers, and turn-mill machining centers. The company also offers FA products and servomotors.

The Churchill Machine Tool Company Limited began as the manufacturing subsidiary of the machine tool importers Charles Churchill & Company Limited founded in the early 1900s by US-born Charles Churchill (1837–1916). Created out of the personal bankruptcy of Charles Churchill, the company developed to become one of the largest British importers of machine tools from the United States and a major manufacturer of such tools, initially under licence and later of its own development.

Dean, Smith & Grace is a British manufacturer of lathes and milling machines, based in Keighley, West Yorkshire. Their products have been described as "the Rolls-Royce of lathes".

Raymond Arthur Trew is a businessman and former football club chairman from Lincolnshire. He is a former board member of Lincoln City F.C., Notts County F.C., and Notts County Ladies F.C.

Joseph Booth & Bros was an English company notable for making cranes used in large construction projects.

George Cohen, Sons and Company was a scrap metal merchant with offices in Commercial Road, London. The company was founded by George Henry Cohen (d.1890) as Messrs. George Cohen & Co. in 1834 and changed its name to George Cohen, Sons and Co. in 1883 on the appointment of Michael Cohen, son of the founder. After the First World War the company won a number of large contracts to dispose of surplus munitions including "400,000 tons of high explosives and other shells". The company also engaged in demolition work, with projects including the towers of Crystal Palace, which had survived the great fire, the Dome of Discovery and Skylon at the Festival of Britain, and London's tram system. In 1940 the company moved its head offices to Hammersmith.