In commerce, supply chain management (SCM) deals with a system of procurement, operations management, logistics and marketing channels, through which raw materials can be developed into finished products and delivered to their end customers. A more narrow definition of supply chain management is the "design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronising supply with demand and measuring performance globally". This can include the movement and storage of raw materials, work-in-process inventory, finished goods, and end to end order fulfilment from the point of origin to the point of consumption. Interconnected, interrelated or interlinked networks, channels and node businesses combine in the provision of products and services required by end customers in a supply chain.

Logistics is the part of supply chain management that deals with the efficient forward and reverse flow of goods, services, and related information from the point of origin to the point of consumption according to the needs of customers. Logistics management is a component that holds the supply chain together. The resources managed in logistics may include tangible goods such as materials, equipment, and supplies, as well as food and other consumable items.

A supply chain is a complex logistics system that consists of facilities that convert raw materials into finished products and distribute them to end consumers or end customers. Meanwhile, supply chain management deals with the flow of goods in distribution channels within the supply chain in the most efficient manner.

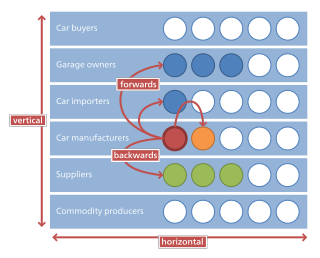

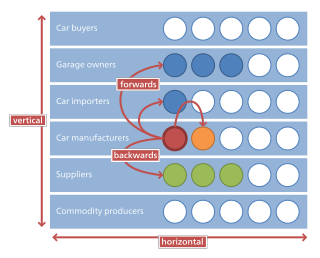

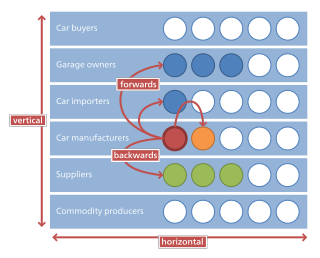

Horizontal integration is the process of a company increasing production of goods or services at the same level of the value chain, in the same industry. A company may do this via internal expansion or through mergers and acquisitions.

In microeconomics, management and international political economy, vertical integration, also referred to as vertical consolidation, is an arrangement in which the supply chain of a company is integrated and owned by that company. Usually each member of the supply chain produces a different product or (market-specific) service, and the products combine to satisfy a common need. It contrasts with horizontal integration, wherein a company produces several items that are related to one another. Vertical integration has also described management styles that bring large portions of the supply chain not only under a common ownership but also into one corporation.

A value chain is a progression of activities that a business or firm performs in order to deliver goods and services of value to an end customer. The concept comes from the field of business management and was first described by Michael Porter in his 1985 best-seller, Competitive Advantage: Creating and Sustaining Superior Performance.

The idea of [Porter's Value Chain] is based on the process view of organizations, the idea of seeing a manufacturing organization as a system, made up of subsystems each with inputs, transformation processes and outputs. Inputs, transformation processes, and outputs involve the acquisition and consumption of resources – money, labour, materials, equipment, buildings, land, administration and management. How value chain activities are carried out determines costs and affects profits.

Social exchange theory is a sociological and psychological theory that studies the social behavior in the interaction of two parties that implement a cost-benefit analysis to determine risks and benefits. The theory also involves economic relationships—the cost-benefit analysis occurs when each party has goods that the other parties value. Social exchange theory suggests that these calculations occur in romantic relationships, friendships, professional relationships, and ephemeral relationships as simple as exchanging words with a customer at the cash register. Social exchange theory says that if the costs of the relationship are higher than the rewards, such as if a lot of effort or money were put into a relationship and not reciprocated, then the relationship may be terminated or abandoned.

Agribusiness is the industry, enterprises, and the field of study of value chains in agriculture and in the bio-economy, in which case it is also called bio-business or bio-enterprise. The primary goal of agribusiness is to maximize profit while satisfying the needs of consumers for products related to natural resources such as biotechnology, farms, food, forestry, fisheries, fuel, and fiber.

There is no agreed definition of value networks. A general definition that subsumes the other definitions is that a value network is a network of roles linked by interactions in which economic entities engage in both tangible and intangible exchanges to achieve economic or social good. This is close to the definition of Verna Allee, see below. Here are a few definitions that provide different perspectives on the general concept of a value network.

Critical success factor (CSF) is a management term for an element s necessary for an organization or project to achieve its mission. To achieve their goals they need to be aware of each key success factor (KSF) and the variations between the keys and the different roles key result area (KRA).

Business-to-business is a situation where one business makes a commercial transaction with another. This typically occurs when:

A lead time is the latency between the initiation and completion of a process. For example, the lead time between the placement of an order and delivery of new cars by a given manufacturer might be between 2 weeks and 6 months, depending on various particularities. One business dictionary defines "manufacturing lead time" as the total time required to manufacture an item, including order preparation time, queue time, setup time, run time, move time, inspection time, and put-away time. For make-to-order products, it is the time between release of an order and the production and shipment that fulfill that order. For make-to-stock products, it is the time taken from the release of an order to production and receipt into finished goods inventory.

Supplier relationship management (SRM) is the systematic, enterprise-wide assessment of suppliers' strengths, performance and capabilities with respect to overall business strategy, determination of what activities to engage in with different suppliers, and planning and execution of all interactions with suppliers, in a coordinated fashion across the relationship life cycle, to maximize the value realized through those interactions. The focus of supplier relationship management is the development of two-way, mutually beneficial relationships with strategic supply partners to deliver greater levels of innovation and competitive advantage than could be achieved by operating independently or through a traditional, transactional purchasing arrangement. Underpinning disciplines which support effective SRM include supplier information management, compliance, risk management and performance management.

The Supply Chain Operations Reference (SCOR) model is a process reference model originally developed and endorsed by the Supply Chain Council, now a part of ASCM, as the cross-industry, standard diagnostic tool for supply chain management. The SCOR model describes the business activities associated with satisfying a customer's demand, which include plan, source, make, deliver, return, and enable. Use of the model includes analyzing the current state of a company's processes and goals, quantifying operational performance, and comparing company performance to benchmark data. SCOR has developed a set of metrics for supply chain performance, and ASCM members have formed industry groups to collect best practices information that companies can use to elevate their supply chain models.

A supply-chain network (SCN) is an evolution of the basic supply chain. Due to rapid technological advancement, organizations with a basic supply chain can develop this chain into a more complex structure involving a higher level of interdependence and connectivity between more organizations, this constitutes a supply-chain network.

Third-party logistics is an organization's long term commitment of outsourcing its distribution services to third-party logistics businesses.

This article outlines the evolution of management systems. A management system is the framework of processes and procedures used to ensure that an organization can fulfill all tasks required to achieve its objectives.

Global Production Networks (GPN) is a concept in developmental literature which refers to "the nexus of interconnected functions, operations and transactions through which a specific product or service is produced, distributed and consumed."

Co-opetition or coopetition – simultaneous competition and cooperation – is an important philosophy or strategy that goes beyond the conventional rules of competition and cooperation to achieve advantages of both. Global co-opetition, an application of co-opetition in a global context, is first systematically addressed in Luo’s (2004) book “Coopetition in international business”. According to this book, global co-opetition refers to the simultaneous competition and cooperation between multinational enterprises (MNEs) and their geographically dispersed business stakeholders such as global rivals, global suppliers, global distributors, global alliance partners, and foreign governments as well as among foreign subsidiaries within an MNE.

In supply chain management, supply chain collaboration is defined as two or more autonomous firms working jointly to plan and execute supply chain operations. It can deliver substantial benefits and advantages to collaborators. It is known as a cooperative strategy when one or more companies or business units work together to create mutual benefits. There are two main types of supply chain collaboration: vertical collaboration and horizontal collaboration. Vertical collaboration is the collaboration when two or more organizations from different levels or stages in supply chain share their responsibilities, resources, and performance information to serve relatively similar end customers; while horizontal collaboration is an inter-organizational systemrelationship between two or more companies at the same level or stage in the supply chain in order to allow greater ease of work and cooperation towards achieving a common objective.