The SB-33 is a small Italian minimum metal blast type anti-personnel mine formerly manufactured by Misar, that entered service in 1977. The SB-33 can be emplaced by hand or scattered using the helicopter mounted SY-AT system.

The PT Mi-Ba-II is a large Bakerlite cased Czechoslovakian anti-tank blast mine. The mine is unusual in that it has two plunger fuses instead of a pressure plate. The plunger fuses give the mine resistance to overpressure, also the plastic body makes it difficult to detect.

The VS-50 is a circular plastic cased anti-personnel blast mine, formerly manufactured by the now-defunct Valsella Meccanotecnica SpA, an Italian high-tech defence industry specialized in area denial systems which was also the manufacturer of the Valmara 69 and one of the first industries in the world to implement plastic construction for landmines. The design is similar to the TS-50 and VS-MK2 mine. It is blast resistant and can be used in a minimum metal configuration. Though unlikely to kill, the explosive charge contained within a VS-50 is quite sufficient to destroy the victim's foot: the blast is capable of penetrating 5 mm of mild steel leaving an 80 mm-diameter hole.

The PT Mi-K is a Czechoslovakian metal-cased anti-tank blast landmine. The mine uses a metal grid instead a pressure plate, this gives it resistance to overpressure. The mine is no longer produced, but is found in Afghanistan, Cambodia, Eritrea, Namibia, Nicaragua and the Western Sahara.

The M7 is a small, metal-cased United States anti-tank blast mine that was used during the Second World War. It was based on the British Hawkins grenade. Approximately 2.5 million were produced before production ceased, and although it has long since been withdrawn from U.S. service, it can be found in Angola, Burma, Cambodia, Chad, Eritrea, Ethiopia, Korea, Lebanon, Myanmar, Somalia, Thailand, and Zambia.

The FMK-3 is a fibreglass cased Argentine anti-tank blast mine. It is produced by Direccion General de Fabricaciones Militares. The mine actually uses a FMK-1 anti-personnel mine as a fuze, the FMK-1 is modified with a pressure cap to increase the activation pressure. Argentina's stock of FMK-1 mines was modified in 2003 to prevent their use as anti-personnel mines, this involved welded an additional plastic pressure cap onto the mine. The mine has very little metal content, although an optional detection ring is provided with the FMK-1.

The M21 is a circular United States anti-tank landmine that uses a Misznay Schardin effect warhead. The mine uses an M607 pressure fuse, which can be adapted as a tilt rod fuze. The mine is triggered either by pressure, or by the tilt rod being forced beyond 20 degrees from the vertical by a force of more than 1.7 kg, either of these actions results in pressure being transferred via a bearing cap to a Belleville spring, which inverts, driving the firing pin into the M46 detonator. The M46 charge first ignites a black powder charge, which blows off the mine's cover, and clears any earth or debris that may have been on top of the mine. A fraction of a second later the main warhead detonates, driving and compressing a steel plate upwards, with enough force to penetrate 76 mm of armour at a distance of 530 mm. Approximately 200,000 M21 mines were produced in the U.S. and a licensed copies, the K441 and K442, were produced in South Korea.

The P2 Mk2 and P3 Mk2 are Pakistani plastic cased minimum metal anti-tank blast mines. The P2 Mk2 has a square case with a central circular ribbed pressure plate, the P3 is circular with a central circular pressure plate. Both mines use anti-personnel mines as the fuse, typically the either the P4 Mk1 or P2 Mk2 anti-personnel mines. The anti-personnel mine sits in a cavity below the pressure plate, when enough pressure is place on the pressure plate of the mine, it collapses onto the anti-personnel mine triggering it and the main charge which sits below it. A yellow canvas carrying strap is normally fitted to the side of the mine. The mines have a secondary fuse well on the bottom which can be used with anti-handling devices. A GLM-2 electronic booby trap can be fitted to the cavity under the pressure plate. The mine is supplied with a steel disc which makes the mine more easily detectable, although this is seldom used. Since 1997 only a detectable version of the mine has been produced, and to comply with the Convention on Conventional Weapons amended protocol II, Pakistani stocks of the mine are being retrofitted with steel detection discs. The mines are found in Afghanistan, Angola, Eritrea, Ethiopia, Pakistan, Somalia, and Tajikistan.

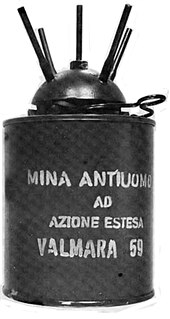

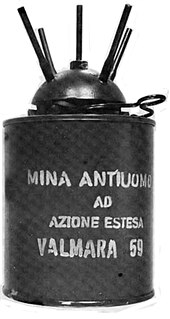

The Valmara 59 is a large cylindrical Italian bounding anti-personnel mine. It is the first in the "Valmara" family of mines produced by Valsella Meccanotecnica, and was followed by the Valmara 69 and VS-JAP. The mine's body is metal with a distinctive five-pronged head. The central prong has a hole, to allow the threading a trip wire. The inner body of the mine has a main charge surrounded with approximately 1,000 steel cubes, below which is a steel wire connecting it to the base of the mine. When the mine is triggered a small charge launches the mine into the air approximately 45 cm before the steel wire is pulled taut, the jolt of which pulls a striker into the detonator. A secondary time fuse triggers the mine after three seconds if it has not detonated after being triggered.

The VS-JAP is an Italian bounding anti-personnel mine. It is the latest of the Valmara family of bounding mines that includes the Valmara 59 and Valmara 69. The mine has a waterproof plastic faceted cylindrical body with a three-pronged cap, with a central fixing point for a tripwire. The fuze is triggered via downward or sideways pressure.

The TM 65 is a circular Finnish minimum metal anti-tank blast mine. It is broadly based on the Russian TM-62 mine. The mines body is made from a thin shell of fibreglass over a cast block of explosive, with a central fuze well that holds the pressure fuze. The original TM 65 used a US-65 fuze as used in the SM-65 anti-personnel mine, the later TM 65 77 uses a pressure fuze similar to the Russian MV-5 fuze called Painesytytin 77.

The T-AB-1 is a rectangular plastic cased Brazilian anti-tank blast mine. The mine uses a T-AB-1 anti-personnel mine as a fuze. The AP mine is inserted into the body of the AT mine under a large stiff ABS plastic pressure plate. The pressure plate is fastened in place by a number of shear pins, which are designed to give way under a pressure of 200 kg. The AP mine under the pressure plate is then triggered, triggering the mine's main charge.

The MPP-B "Wierzba" is a fibreglass Polish minimum metal anti-tank blast mine. The mine is similar to the Russian TM-62 series and is compatible with the same fuses. It is normally used with a MWCz-62 fuse with a clockwork arming delay, which is a copy of the Russian MVCh-62. The mine has a secondary fuse well in the base of the mine for anti-handling devices or for a command detonation device. It can also be used with a ZMN electronic combined pressure and magnetic influence fuse.

The MATS/2 is a scatterable Italian circular, plastic-cased minimum metal blast resistant anti-tank blast mine. It uses a pneumatic fuse which is resistant to shock and blast similar to the fuse fitted to the TS-50. The mine's plastic case is waterproof, and the mine can be scattered from a helicopter traveling at up to 200 km/h using the Tecnovar DAT dispensing system. A secondary fuse well is provided in the base for the fitting of anti-handling devices.

The AUPS is a circular Italian bakelite cased minimum metal anti-personnel blast mine. The mine can be adapted with a steel fragmentation jacket and stake into a fragmentation stake mine. The mine is constructed in two halves, with the upper half containing the pressure fuse mechanism, the lower half contains the main charge and the detonator. The mine case is normally unpainted bakelite brown.

The NR-413 is a Belgian trip wire activated anti-personnel stake mine. The main body of the mine is wine bottle shaped, with an NR 410 tripwire fuse screwed into a fuse well on the top of the mine. Under the fuse well is a detonator and a row of booster pellets. Wrapped around the detonator and booster pellets is the main charge. An internally square cross-sectioned steel wire is coiled around the outside of the mine, which give a fragmentation effect. The mine produces 600 fragments with a velocity of approximately 1,660 metres per second. It has an effective range of around 15 metres. A variant is produced with a cast steel fragmentation jacket.

The P-25 is a plastic cased Italian anti-personnel stake mine. It was developed along with the larger P-40 mine in the late 1970s by Misar SpA and entered production in 1978. The mine consists of a plastic cylinder with a fuse protruding from the top. The mine can either be stake mounted or buried, although it was designed to be stake mounted. Pull pressure on the tripwire results in the fuse head tilting sideways, releasing a striker into the detonator assembly.

The PPMP-2 is a Yugoslavian anti-personnel stake mine. The mine was not mass-produced, but was built in large quantities at a number of different locations.

The Min AP NM AE T1 is a small Brazilian minimum metal anti-personnel mine. The mine has a plastic case in the form of a truncated cone. with a small protruding fuse and pressure plate. The small size of the pressure plate gives the mine some blast resistance. The main charge is in the form of a small inverted cone which generates a shaped charge effect when detonated.

The TS-50 is a 90 mm (3.5 in) diameter circular Italian blast resistant minimum metal anti-personnel mine designed and produced by Valsella Meccanotecnica.