An oil spill is the release of a liquid petroleum hydrocarbon into the environment, especially the marine ecosystem, due to human activity, and is a form of pollution. The term is usually given to marine oil spills, where oil is released into the ocean or coastal waters, but spills may also occur on land. Oil spills can result from the release of crude oil from tankers, offshore platforms, drilling rigs, and wells. They may also involve spills of refined petroleum products, such as gasoline and diesel fuel, as well as their by-products. Additionally, heavier fuels used by large ships, such as bunker fuel, or spills of any oily refuse or waste oil, contribute to such incidents. These spills can have severe environmental and economic consequences.

Biodiesel is a renewable biofuel, a form of diesel fuel, derived from biological sources like vegetable oils, animal fats, or recycled greases, and consisting of long-chain fatty acid esters. It is typically made from fats.

Motor oil, engine oil, or engine lubricant is any one of various substances used for the lubrication of internal combustion engines. They typically consist of base oils enhanced with various additives, particularly antiwear additives, detergents, dispersants, and, for multi-grade oils, viscosity index improvers. The main function of motor oil is to reduce friction and wear on moving parts and to clean the engine from sludge and varnish (detergents). It also neutralizes acids that originate from fuel and from oxidation of the lubricant (detergents), improves the sealing of piston rings, and cools the engine by carrying heat away from moving parts.

The pyrethrins are a class of organic compounds normally derived from Chrysanthemum cinerariifolium that have potent insecticidal activity by targeting the nervous systems of insects. Pyrethrin naturally occurs in chrysanthemum flowers and is often considered an organic insecticide when it is not combined with piperonyl butoxide or other synthetic adjuvants. Their insecticidal and insect-repellent properties have been known and used for thousands of years.

Pentachlorophenol (PCP) is an organochlorine compound used as a pesticide and a disinfectant. First produced in the 1930s, it is marketed under many trade names. It can be found as pure PCP, or as the sodium salt of PCP, the latter of which dissolves easily in water. It can be biodegraded by some bacteria, including Sphingobium chlorophenolicum.

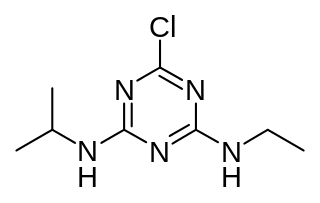

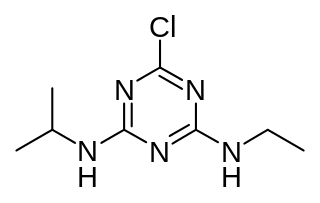

Atrazine is a chlorinated herbicide of the triazine class. It is used to prevent pre-emergence broadleaf weeds in crops such as maize (corn), soybean and sugarcane and on turf, such as golf courses and residential lawns. Atrazine's primary manufacturer is Syngenta and it is one of the most widely used herbicides in the United States, Canadian, and Australian agriculture. Its use was banned in the European Union in 2004, when the EU found groundwater levels exceeding the limits set by regulators, and Syngenta could not show that this could be prevented nor that these levels were safe.

2-Butoxyethanol is an organic compound with the chemical formula BuOC2H4OH. This colorless liquid has a sweet, ether-like odor, as it derives from the family of glycol ethers, and is a butyl ether of ethylene glycol. As a relatively nonvolatile, inexpensive solvent, it is used in many domestic and industrial products because of its properties as a surfactant. It is a known respiratory irritant and can be acutely toxic, but animal studies did not find it to be mutagenic, and no studies suggest it is a human carcinogen. A study of 13 classroom air contaminants conducted in Portugal reported a statistically significant association with increased rates of nasal obstruction and a positive association below the level of statistical significance with a higher risk of obese asthma and increased body mass index.

Heavy crude oil is highly viscous oil that cannot easily flow from production wells under normal reservoir conditions.

Bonny Light oil was found at Oloibiri in the Niger delta region of Nigeria in 1956 for its commercial use. Due to its features of generating high profit, it is highly demanded by refiners. Bonny light oil has an API of 32.9, classified as light oil. It is regarded as more valuable than the other oils with lower API as more high-value products are produced in the refinement. However, in Nigeria, problems due to oil spillage caused by vandalism, affects both human and the ecosystem in detrimental ways. Some experiments on animals and soil are done to figure out those impacts on organisms.

Firefighting foam is a foam used for fire suppression. Its role is to cool the fire and to coat the fuel, preventing its contact with oxygen, thus achieving suppression of the combustion. Firefighting foam was invented by the Moldovan engineer and chemist Aleksandr Loran in 1902.

Dilbit is a bitumen diluted with one or more lighter petroleum products, typically natural-gas condensates such as naphtha. Diluting bitumen makes it much easier to transport, for example in pipelines. Per the Alberta Oil Sands Bitumen Valuation Methodology, "Dilbit Blends" means "Blends made from heavy crudes and/or bitumens and a diluent, usually natural-gas condensate, for the purpose of meeting pipeline viscosity and density specifications, where the density of the diluent included in the blend is less than 800 kg/m3." If the diluent density is greater than or equal to 800 kg/m3, the diluent is typically synthetic crude and accordingly the blend is called synbit.

A spray nozzle or atomizer is a device that facilitates the dispersion of a liquid by the formation of a spray. The production of a spray requires the fragmentation of liquid structures, such as liquid sheets or ligaments, into droplets, often by using kinetic energy to overcome the cost of creating additional surface area. A wide variety of spray nozzles exist, that make use of one or multiple liquid breakup mechanisms, which can be divided into three categories: liquid sheet breakup, jets and capillary waves. Spray nozzles are of great importance for many applications, where the spray nozzle is designed to have the right spray characteristics.

Simple Green is an American brand of cleaning products produced by Sunshine Makers, Inc. Their best known product is Simple Green All-Purpose Cleaner, which totaled sales of at least US$5.7 million in 2004.

The environmental impact of the petroleum industry is extensive and expansive due to petroleum having many uses. Crude oil and natural gas are primary energy and raw material sources that enable numerous aspects of modern daily life and the world economy. Their supply has grown quickly over the last 150 years to meet the demands of the rapidly increasing human population, creativity, knowledge, and consumerism.

Corexit is a product line of oil dispersants used during oil spill response operations. It is produced by Nalco Holding Company, an indirect subsidiary of Ecolab. Corexit was originally developed by the Standard Oil Company of New Jersey. Corexit is typically applied by aerial spraying or spraying from ships directly onto an oil slick. On contact with the dispersant, oil that would otherwise float on the surface of the water is emulsified into tiny droplets and sinks or remains suspended in the water. In theory this allows the oil to be more rapidly degraded by bacteria (bioremediation) and prevents it from accumulating on beaches and in marshes.

An oil dispersant is a mixture of emulsifiers and solvents that helps break oil into small droplets following an oil spill. Small droplets are easier to disperse throughout a water volume, and small droplets may be more readily biodegraded by microbes in the water. Dispersant use involves a trade-off between exposing coastal life to surface oil and exposing aquatic life to dispersed oil. While submerging the oil with dispersant may lessen exposure to marine life on the surface, it increases exposure for animals dwelling underwater, who may be harmed by toxicity of both dispersed oil and dispersant. Although dispersant reduces the amount of oil that lands ashore, it may allow faster, deeper penetration of oil into coastal terrain, where it is not easily biodegraded.

The Deepwater Horizon oil spill occurred between 10 April and 19 September 2010 in the Gulf of Mexico. A variety of techniques were used to address fundamental strategies for addressing the spilled oil, which were: to contain oil on the surface, dispersal, and removal. While most of the oil drilled off Louisiana is a lighter crude, the leaking oil was of a heavier blend which contained asphalt-like substances. According to Ed Overton, who heads a federal chemical hazard assessment team for oil spills, this type of oil emulsifies well. Once it becomes emulsified, it no longer evaporates as quickly as regular oil, does not rinse off as easily, cannot be broken down by microbes as easily, and does not burn as well. "That type of mixture essentially removes all the best oil clean-up weapons", Overton said.

The 2013 Mayflower oil spill occurred on March 29, 2013, when the Pegasus Pipeline, owned by ExxonMobil and carrying Canadian Wabasca heavy crude from the Athabasca oil sands, ruptured in Mayflower, Arkansas, about 25 miles (40 km) northwest of Little Rock releasing about 3,190 barrels of oil. Approximately 3,190 barrels of oil and water mix was recovered. Twenty-two homes were evacuated. The United States Environmental Protection Agency (EPA) classified the leak as a major spill.

Petroleum microbiology is a branch of microbiology that deals with the study of microorganisms that can metabolize or alter crude or refined petroleum products. These microorganisms, also called hydrocarbonoclastic microorganisms, can degrade hydrocarbons and, include a wide distribution of bacteria, methanogenic archaea, and some fungi. Not all hydrocarbonoclasic microbes depend on hydrocarbons to survive, but instead may use petroleum products as alternative carbon and energy sources. Interest in this field is growing due to the increasing use of bioremediation of oil spills.

Bioremediation of petroleum contaminated environments is a process in which the biological pathways within microorganisms or plants are used to degrade or sequester toxic hydrocarbons, heavy metals, and other volatile organic compounds found within fossil fuels. Oil spills happen frequently at varying degrees along with all aspects of the petroleum supply chain, presenting a complex array of issues for both environmental and public health. While traditional cleanup methods such as chemical or manual containment and removal often result in rapid results, bioremediation is less labor-intensive, expensive, and averts chemical or mechanical damage. The efficiency and effectiveness of bioremediation efforts are based on maintaining ideal conditions, such as pH, RED-OX potential, temperature, moisture, oxygen abundance, nutrient availability, soil composition, and pollutant structure, for the desired organism or biological pathway to facilitate reactions. Three main types of bioremediation used for petroleum spills include microbial remediation, phytoremediation, and mycoremediation. Bioremediation has been implemented in various notable oil spills including the 1989 Exxon Valdez incident where the application of fertilizer on affected shoreline increased rates of biodegradation.