Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding against each other. Types of friction include dry, fluid, lubricated, skin, and internal -- an incomplete list. The study of the processes involved is called tribology, and has a history of more than 2000 years.

The triboelectric effect describes electric charge transfer between two objects when they contact or slide against each other. It can occur with different materials, such as the sole of a shoe on a carpet, or between two pieces of the same material. It is ubiquitous, and occurs with differing amounts of charge transfer (tribocharge) for all solid materials. There is evidence that tribocharging can occur between combinations of solids, liquids and gases, for instance liquid flowing in a solid tube or an aircraft flying through air.

Atomic force microscopy (AFM) or scanning force microscopy (SFM) is a very-high-resolution type of scanning probe microscopy (SPM), with demonstrated resolution on the order of fractions of a nanometer, more than 1000 times better than the optical diffraction limit.

Tribology is the science and engineering of understanding friction, lubrication and wear phenomena for interacting surfaces in relative motion. It is highly interdisciplinary, drawing on many academic fields, including physics, chemistry, materials science, mathematics, biology and engineering. The fundamental objects of study in tribology are tribosystems, which are physical systems of contacting surfaces. Subfields of tribology include biotribology, nanotribology and space tribology. It is also related to other areas such as the coupling of corrosion and tribology in tribocorrosion and the contact mechanics of how surfaces in contact deform. Approximately 20% of the total energy expenditure of the world is due to the impact of friction and wear in the transportation, manufacturing, power generation, and residential sectors.

An electrical contact is an electrical circuit component found in electrical switches, relays, connectors and circuit breakers. Each contact is a piece of electrically conductive material, typically metal. When a pair of contacts touch, they can pass an electrical current with a certain contact resistance, dependent on surface structure, surface chemistry and contact time; when the pair is separated by an insulating gap, then the pair does not pass a current. When the contacts touch, the switch is closed; when the contacts are separated, the switch is open. The gap must be an insulating medium, such as air, vacuum, oil, SF6. Contacts may be operated by humans in push-buttons and switches, by mechanical pressure in sensors or machine cams, and electromechanically in relays. The surfaces where contacts touch are usually composed of metals such as silver or gold alloys that have high electrical conductivity, wear resistance, oxidation resistance and other properties.

Wetting is the ability of a liquid to displace gas to maintain contact with a solid surface, resulting from intermolecular interactions when the two are brought together. These interactions occur in the presence of either a gaseous phase or another liquid phase not miscible with the wetting liquid. The degree of wetting (wettability) is determined by a force balance between adhesive and cohesive forces. There are two types of wetting: non-reactive wetting and reactive wetting.

Crystal twinning occurs when two or more adjacent crystals of the same mineral are oriented so that they share some of the same crystal lattice points in a symmetrical manner. The result is an intergrowth of two separate crystals that are tightly bonded to each other. The surface along which the lattice points are shared in twinned crystals is called a composition surface or twin plane.

Surface roughness can be regarded as the quality of a surface of not being smooth and it is hence linked to human (haptic) perception of the surface texture. From a mathematical perspective it is related to the spatial variability structure of surfaces, and inherently it is a multiscale property. It has different interpretations and definitions depending on the disciplines considered.

Nanotribology is the branch of tribology that studies friction, wear, adhesion and lubrication phenomena at the nanoscale, where atomic interactions and quantum effects are not negligible. The aim of this discipline is characterizing and modifying surfaces for both scientific and technological purposes.

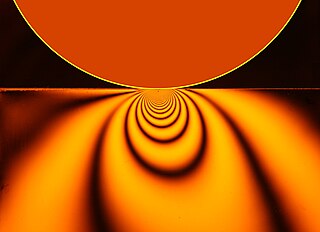

In materials science, asperity, defined as "unevenness of surface, roughness, ruggedness", has implications in physics and seismology. Smooth surfaces, even those polished to a mirror finish, are not truly smooth on a microscopic scale. They are rough, with sharp, rough or rugged projections, termed "asperities". Surface asperities exist across multiple scales, often in a self affine or fractal geometry. The fractal dimension of these structures has been correlated with the contact mechanics exhibited at an interface in terms of friction and contact stiffness.

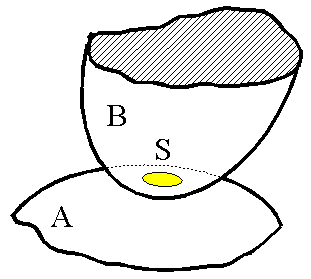

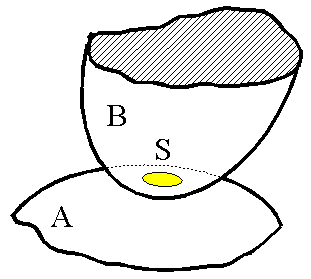

When two objects touch, only a certain portion of their surface areas will be in contact with each other. This area of true contact, most often constitutes only a very small fraction of the apparent or nominal contact area. In relation to two contacting objects, the contact area is the part of the nominal area that consists of atoms of one object in true contact with the atoms of the other object. Because objects are never perfectly flat due to asperities, the actual contact area is usually much less than the contact area apparent on a macroscopic scale. Contact area may depend on the normal force between the two objects due to deformation.

In physics, thermal contact conductance is the study of heat conduction between solid or liquid bodies in thermal contact. The thermal contact conductance coefficient, , is a property indicating the thermal conductivity, or ability to conduct heat, between two bodies in contact. The inverse of this property is termed thermal contact resistance.

In solid mechanics, a shear band is a narrow zone of intense strain due to shearing, usually of plastic nature, developing during severe deformation of ductile materials. As an example, a soil specimen is shown in Fig. 1, after an axialsymmetric compression test. Initially the sample was cylindrical in shape and, since symmetry was tried to be preserved during the test, the cylindrical shape was maintained for a while during the test and the deformation was homogeneous, but at extreme loading two X-shaped shear bands had formed and the subsequent deformation was strongly localized.

Electrical contact resistance is resistance to the flow of electric current caused by incomplete contact of the surfaces through which the current is flowing, and by films or oxide layers on the contacting surfaces. It occurs at electrical connections such as switches, connectors, breakers, contacts, and measurement probes. Contact resistance values are typically small.

The stick–slip phenomenon, also known as the slip–stick phenomenon or simply stick–slip, is a type of motion exhibited by objects in contact sliding over one another. The motion of these objects is usually not perfectly smooth, but rather irregular, with brief accelerations (slips) interrupted by stops (sticks). Stick–slip motion is normally connected to friction, and may generate vibration (noise) or be associated with mechanical wear of the moving objects, and is thus often undesirable in mechanical devices. On the other hand, stick–slip motion can be useful in some situations, such as the movement of a bow across a string to create musical tones in a bowed string instrument.

Contact mechanics is the study of the deformation of solids that touch each other at one or more points. A central distinction in contact mechanics is between stresses acting perpendicular to the contacting bodies' surfaces and frictional stresses acting tangentially between the surfaces. Normal contact mechanics or frictionless contact mechanics focuses on normal stresses caused by applied normal forces and by the adhesion present on surfaces in close contact, even if they are clean and dry. Frictional contact mechanics emphasizes the effect of friction forces.

In contact mechanics, the term unilateral contact, also called unilateral constraint, denotes a mechanical constraint which prevents penetration between two rigid/flexible bodies. Constraints of this kind are omnipresent in non-smooth multibody dynamics applications, such as granular flows, legged robot, vehicle dynamics, particle damping, imperfect joints, or rocket landings. In these applications, the unilateral constraints result in impacts happening, therefore requiring suitable methods to deal with such constraints.

Contact mechanics is the study of the deformation of solids that touch each other at one or more points. This can be divided into compressive and adhesive forces in the direction perpendicular to the interface, and frictional forces in the tangential direction. Frictional contact mechanics is the study of the deformation of bodies in the presence of frictional effects, whereas frictionless contact mechanics assumes the absence of such effects.

Elasto-capillarity is the ability of capillary force to deform an elastic material. From the viewpoint of mechanics, elastocapillarity phenomena essentially involve competition between the elastic strain energy in the bulk and the energy on the surfaces/interfaces. In the modeling of these phenomena, some challenging issues are, among others, the exact characterization of energies at the micro scale, the solution of strongly nonlinear problems of structures with large deformation and moving boundary conditions, and instability of either solid structures or droplets/films.The capillary forces are generally negligible in the analysis of macroscopic structures but often play a significant role in many phenomena at small scales.

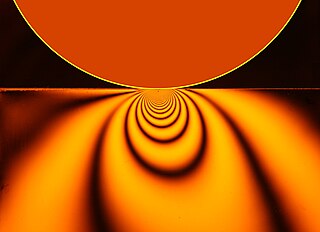

The third medium contact(TMC) is an implicit formulation used in contact mechanics. Contacting bodies are embedded in a highly compliant medium (the third medium), which becomes increasingly stiff under compression. The stiffening of the third medium allows tractions to be transferred between the contacting bodies when the third medium between the bodies is compressed. In itself, the method is inexact; however, in contrast to most other contact methods, the third medium approach is continuous and differentiable, which makes it applicable to applications such as topology optimization.