Horsepower (hp) is a unit of measurement of power, or the rate at which work is done, usually in reference to the output of engines or motors. There are many different standards and types of horsepower. Two common definitions used today are the imperial horsepower, which is about 745.7 watts, and the metric horsepower, which is approximately 735.5 watts.

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod. In a pump, the function is reversed and force is transferred from the crankshaft to the piston for the purpose of compressing or ejecting the fluid in the cylinder. In some engines, the piston also acts as a valve by covering and uncovering ports in the cylinder.

A reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common features of all types. The main types are: the internal combustion engine, used extensively in motor vehicles; the steam engine, the mainstay of the Industrial Revolution; and the Stirling engine for niche applications. Internal combustion engines are further classified in two ways: either a spark-ignition (SI) engine, where the spark plug initiates the combustion; or a compression-ignition (CI) engine, where the air within the cylinder is compressed, thus heating it, so that the heated air ignites fuel that is injected then or earlier.

A two-strokeengine is a type of internal combustion engine that completes a power cycle with two strokes of the piston in one revolution of the crankshaft. A four-stroke engine requires four strokes of the piston to complete a power cycle in two crankshaft revolutions. In a two-stroke engine, the end of the combustion stroke and the beginning of the compression stroke happen simultaneously, with the intake and exhaust functions occurring at the same time.

In mechanical engineering, a crosshead is a mechanical joint used as part of the slider-crank linkages of long reciprocating engines and reciprocating compressors to eliminate sideways force on the piston. Also, the crosshead enables the connecting rod to freely move outside the cylinder. Because of the very small bore-to-stroke ratio on such engines, the connecting rod would hit the cylinder walls and block the engine from rotating if the piston was attached directly to the connecting rod like on trunk engines. Therefore, the longitudinal dimension of the crosshead must be matched to the stroke of the engine.

Top Fuel is a type of drag racing whose dragsters are the quickest accelerating racing cars in the world and the fastest sanctioned category of drag racing, with the fastest competitors reaching speeds of 338 miles per hour (544.0 km/h) and finishing the 1,000 foot (304.8 m) runs in 3.62 seconds.

An opposed-piston engine is a piston engine in which each cylinder has a piston at both ends, and no cylinder head. Petrol and diesel opposed-piston engines have been used mostly in large-scale applications such as ships, military tanks, and factories. Current manufacturers of opposed-piston engines include Cummins, Achates Power and Fairbanks-Morse Defense (FMDefense).

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the crankshaft. The connecting rod is required to transmit the compressive and tensile forces from the piston. In its most common form, in an internal combustion engine, it allows pivoting on the piston end and rotation on the shaft end.

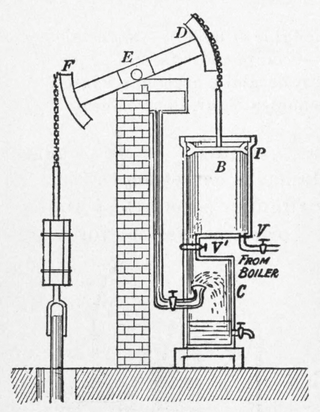

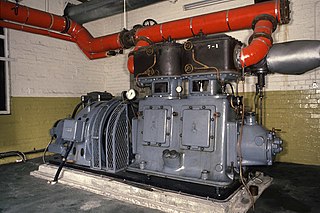

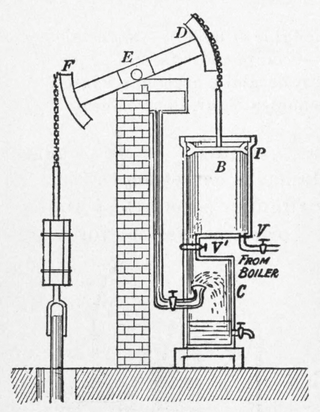

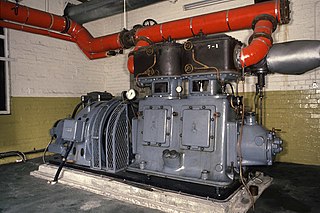

Stationary steam engines are fixed steam engines used for pumping or driving mills and factories, and for power generation. They are distinct from locomotive engines used on railways, traction engines for heavy steam haulage on roads, steam cars, agricultural engines used for ploughing or threshing, marine engines, and the steam turbines used as the mechanism of power generation for most nuclear power plants.

Engine braking occurs when the retarding forces within an internal combustion engine are used to slow down a motor vehicle, as opposed to using additional external braking mechanisms such as friction brakes or magnetic brakes.

A crankcase is the housing in a piston engine that surrounds the crankshaft. In most modern engines, the crankcase is integrated into the engine block.

The hot-bulb engine, also known as a semi-diesel, is a type of internal combustion engine in which fuel ignites by coming in contact with a red-hot metal surface inside a bulb, followed by the introduction of air (oxygen) compressed into the hot-bulb chamber by the rising piston. There is some ignition when the fuel is introduced, but it quickly uses up the available oxygen in the bulb. Vigorous ignition takes place only when sufficient oxygen is supplied to the hot-bulb chamber on the compression stroke of the engine.

A marine steam engine is a steam engine that is used to power a ship or boat. This article deals mainly with marine steam engines of the reciprocating type, which were in use from the inception of the steamboat in the early 19th century to their last years of large-scale manufacture during World War II. Reciprocating steam engines were progressively replaced in marine applications during the 20th century by steam turbines and marine diesel engines.

The South African Railways Class 25NC 4-8-4 of 1953 was a class of steam locomotives built between 1953 and 1955 for the South African Railways (SAR). The Class 25NC was the non-condensing version of the Class 25 condensing locomotive, of which ninety were placed in service at the same time. Between 1973 and 1980, all but three of the condensing locomotives were converted to non-condensing and also designated Class 25NC.

In mechanical engineering, the cylinders of reciprocating engines are often classified by whether they are single- or double-acting, depending on how the working fluid acts on the piston.

High-speed steam engines were one of the final developments of the stationary steam engine. They ran at a high speed, of several hundred rpm, which was needed by tasks such as electricity generation.

The Cyclone Mark V Engine is a steam engine in which the engine, steam generator, condenser and feed pump are integrated into a single compact unit. The company Cyclone Power Technologies of Pompano Beach, Florida was founded by inventor Harry Schoell to develop and market this engine. The Cyclone Mark V Engine is a six cylinder radial uniflow engine of two inch bore and two inch stroke. Pistons are single acting. The engine is claimed to produce 100 hp at 3,600 rpm using steam at 3,200 psi and 1,200 °F.

An internal combustion engine is a heat engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons, turbine blades, a rotor, or a nozzle. This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to.

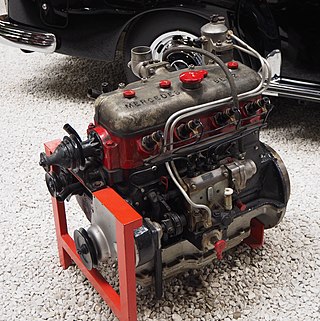

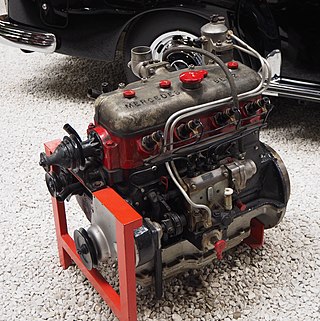

The Mercedes-Benz OM 138 is a diesel engine manufactured by Daimler-Benz. In total, 5,719 units were produced between 1935 and 1940. It was the first diesel engine especially developed and made for a passenger car. The first vehicle powered by the OM 138 was the Mercedes-Benz W 138. The light Mercedes-Benz trucks L 1100 and L 1500 as well as the bus O 1500 were also offered with the OM 138 as an alternative to the standard Otto engine.

Stuart Turner Ltd is a British engineering company, based in Henley-on-Thames, Oxfordshire, England, founded by engineer Sidney Marmaduke Stuart Turner in 1906.