Related Research Articles

Natural-gas condensate, also called natural gas liquids, is a low-density mixture of hydrocarbon liquids that are present as gaseous components in the raw natural gas produced from many natural gas fields. Some gas species within the raw natural gas will condense to a liquid state if the temperature is reduced to below the hydrocarbon dew point temperature at a set pressure.

An oil terminal is an industrial facility for the storage of oil, petroleum and petrochemical products, and from which these products are transported to end users or other storage facilities. An oil terminal typically has a variety of above or below ground tankage; facilities for inter-tank transfer; pumping facilities; loading gantries for filling road tankers or barges; ship loading/unloading equipment at marine terminals; and pipeline connections.

In the upstream oil industry, a gas–oil separation plant (GOSP) is temporary or permanent facilities that separate wellhead fluids into constituent vapor (gas) and liquid components.

The oil and gas industry is usually divided into three major components: upstream, midstream and downstream. The midstream sector involves the transportation, storage, and wholesale marketing of crude or refined petroleum products. Pipelines and other transport systems can be used to move crude oil from production sites to refineries and deliver the various refined products to downstream distributors. Natural gas pipeline networks aggregate gas from natural gas purification plants and deliver it to downstream customers, such as local utilities.

A coalescer is a device which induces coalescence in a medium. They are primarily used to separate emulsions into their components via various processes, operating in reverse to an emulsifier.

Canada's natural gas liquids industry dates back to the discovery of wet natural gas at Turner Valley, Alberta in 1914. The gas was less important than the natural gasoline - "skunk gas" it was called, because of its distinctive odour - that early producers extracted from it. That natural gas liquid (NGL) could be poured directly into an automobile's fuel tank.

Natural-gas processing is a range of industrial processes designed to purify raw natural gas by removing contaminants such as solids, water, carbon dioxide (CO2), hydrogen sulfide (H2S), mercury and higher molecular mass hydrocarbons (condensate) to produce pipeline quality dry natural gas for pipeline distribution and final use. Some of the substances which contaminate natural gas have economic value and are further processed or sold. Hydrocarbons that are liquid at ambient conditions: temperature and pressure (i.e., pentane and heavier) are called natural-gas condensate (sometimes also called natural gasoline or simply condensate).

The Schiehallion oilfield is a deepwater offshore oilfield approximately 175 kilometres (110 mi) west of the Shetland Islands in the North Atlantic Ocean. The Schiehallion and adjacent Loyal field were jointly developed by BP on behalf of the Schiehallion field partners; BP, Shell, Amerada Hess, Murphy Oil, Statoil and OMV, and the Loyal field partners; BP and Shell.

An oil production plant is a facility which processes production fluids from oil wells in order to separate out key components and prepare them for export. Typical oil well production fluids are a mixture of oil, gas and produced water. An oil production plant is distinct from an oil depot, which does not have processing facilities.

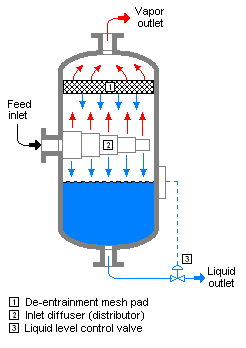

The term separator in oilfield terminology designates a pressure vessel used for separating well fluids produced from oil and gas wells into gaseous and liquid components. A separator for petroleum production is a large vessel designed to separate production fluids into their constituent components of oil, gas and water. A separating vessel may be referred to in the following ways: Oil and gas separator, Separator, Stage separator, Trap, Knockout vessel, Flash chamber, Expansion separator or expansion vessel, Scrubber, Filter. These separating vessels are normally used on a producing lease or platform near the wellhead, manifold, or tank battery to separate fluids produced from oil and gas wells into oil and gas or liquid and gas. An oil and gas separator generally includes the following essential components and features:

- A vessel that includes (a) primary separation device and/or section, (b) secondary "gravity" settling (separating) section, (c) mist extractor to remove small liquid particles from the gas, (d) gas outlet, (e) liquid settling (separating) section to remove gas or vapor from oil, (f) oil outlet, and (g) water outlet.

- Adequate volumetric liquid capacity to handle liquid surges (slugs) from the wells and/or flowlines.

- Adequate vessel diameter and height or length to allow most of the liquid to separate from the gas so that the mist extractor will not be flooded.

- A means of controlling an oil level in the separator, which usually includes a liquid-level controller and a diaphragm motor valve on the oil outlet.

- A back pressure valve on the gas outlet to maintain a steady pressure in the vessel.

- Pressure relief devices.

"Offshore", when used in relation to hydrocarbons, refers to operations undertaken at, or under the, sea in association with an oil, natural gas or condensate field that is under the seabed, or to activities carried out in relation to such a field. Offshore is part of the upstream sector of the oil and gas industry.

In chemical engineering, a vapor–liquid separator is a device used to separate a vapor–liquid mixture into its constituent phases. It can be a vertical or horizontal vessel, and can act as a 2-phase or 3-phase separator.

The Central Area Transmission System is a natural gas transportation and processing system that transports natural gas through a 404 kilometre pipeline from the Central North Sea to a reception and processing terminal at Teesside in the North East of England.

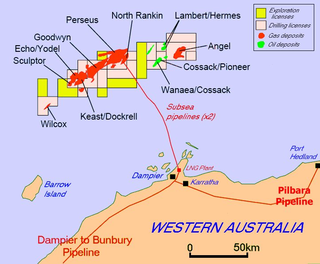

The North West Shelf Venture, situated in the north-west of Western Australia, is Australia's largest resource development project. It involves the extraction of petroleum at offshore production platforms, onshore processing and export of liquefied natural gas, and production of natural gas for industrial, commercial and domestic use within the state.

The petroleum industry in Western Australia is the largest contributor to the country's petroleum exports. Western Australia's North West Shelf (NWS) is the primary location from which production originates. Oil exports are shipped from Port Hedland.

In an oil and gas production, flash-gas is a spontaneous vapor that is produced from the heating or depressurization of the extracted oil mixture during different phases of production. Flash evaporation, or flashing, is the process of volatile components suddenly vaporizing from their liquid state. This often happens during the transportation of petroleum products through pipelines and into vessels, such as when the stream from a common separation unit flows into an on-site atmospheric storage tank. Vessels that are used to intentionally “flash” a mixture of gas and saturated liquids are aptly named "flash drums." A type of vapor-liquid separator. A venting apparatus is used in these vessels to prevent damage due to increasing pressure, extreme cases of this are referred to as boiling liquid expanding vapor explosion (BLEVE).

SNOC is an Oil and Gas producer based in Sharjah, UAE. Established by Emiri decree in 2010, SNOC is a corporation wholly owned by the government of the Emirate of Sharjah. SNOC is the operator of the Sajaa Assets located in Sharjah, UAE. The Sajaa Assets consist of four gas fields, a hydrocarbon processing complex and two marine terminals.

The Flotta oil terminal is a major crude oil reception, processing, storage and export facility on the island of Flotta, in the south of Scapa Flow in the Orkney Islands. It receives and processes crude oil delivered by a subsea pipeline from the Piper, Claymore, Tartan and Golden Eagle platforms and associated fields. The terminal includes facilities for exporting stabilised crude oil by tanker.

Crude oil stabilisation is a partial distillation process that renders crude oil suitable for storage in atmospheric tanks, or of a quality suitable for sales or pipeline transportation. Stabilization is achieved by subjecting ‘live’ crude to temperature and pressure conditions in a fractionation vessel, which drives off light hydrocarbon components to form a ‘dead’ or stabilized crude oil with a lower vapor pressure.

The Teesside oil terminal is a major crude oil reception, processing, storage and export facility at Seal Sands, Middlesbrough. It receives and processes crude oil delivered by the subsea NORPIPE pipeline from the Norwegian Ekofisk field and the UK Fulmar and J-Block fields. The terminal includes facilities for exporting stabilised crude oil and liquefied petroleum gases (LPG) by tanker and pipeline.

References

- 1 2 Gas Processors Suppliers Association (2004). Engineering Data Book. Tulsa, Oklahoma: Gas Processors Suppliers Association.

- ↑ Stewart, Maurice (2008). "Surface Production Operations: Design of Oil Handling Systems and Facilities, Volume One, Third Edition". globalspec.com. Retrieved 13 June 2020.

- ↑ "Technical Information (Kinneil terminal)". Ineos. Retrieved 13 June 2020.

- ↑ Typical Reid Vapor Pressure requirements for crude oil range from 10 to 12 psi (70 to 82 kPa) RVP.

- ↑ The Institute of Petroleum (1978). A Guide to North Sea oil and gas technology. London: Heyden & son Ltd. p. 133. ISBN 0855013168.