A shell, in a Military context, is a projectile whose payload contains an explosive, incendiary, or other chemical filling. Originally it was called a bombshell, but "shell" has come to be unambiguous in a military context. Modern usage sometimes includes large solid kinetic projectiles that is properly termed shot. Solid shot may contain a pyrotechnic compound if a tracer or spotting charge is used.

An anti-tank mine is a type of land mine designed to damage or destroy vehicles including tanks and armored fighting vehicles.

Valmara 69 or V-69 is an Italian bounding anti-personnel mine manufactured by Valsella. The mine was developed from the V-59 mine, and although the mine is no longer produced in Italy, a number of copies were produced in other countries e.g. the "SPM-1" manufactured by Singapore.

The MON-50 is a claymore shaped, plastic bodied, directional type of anti-personnel mine designed and manufactured in the Soviet Union. It is designed to wound or kill by explosive fragmentation. The mine first entered service in 1965 and is similar to the American M18 Claymore with a few differences.

The Tellermine 43 was a German circular steel cased anti-tank blast mine used during the Second World War. It was a simplified version of the Tellermine 42, which enabled simpler production techniques. Between March 1943 and the end of World War II, over 3.6 million Tellermine 43s were produced by Germany. Copies of the mine were produced by several countries including Denmark (M/47), France and Yugoslavia (TMM-1).

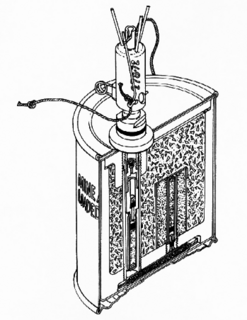

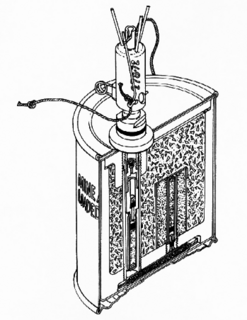

The M16 mine is a United States-made bounding anti-personnel mine. It was based on captured plans of the World War II era German S-mine and has similar performance. The mine consists of a cast iron body in a thin steel sleeve. A central fuze well on the top of the mine is normally fitted with a pronged M605 pressure/tension (tripwire) fuze. Sufficient pressure on the prongs or tension on an attached tripwire causes the release of a striker. The freed striker is forced into a percussion cap which ignites a short pyrotechnic delay. The purpose of this delay is to allow the victim to move off the top of the mine, to prevent its upward movement from being blocked. Once the delay has burned through, a 4.5-gram black powder charge is ignited, which launches the inner iron body of the mine up into the air. The charge also ignites a second pair of pyrotechnic delays.

The TM-57 mine is a large, circular Soviet metal-cased blast anti-tank mine. It can either be triggered by a pressure or a tilt-rod fuze. A development of the TM-46 mine, it is found in Africa, the Middle East, and South East Asia.

The PMN series of blast anti-personnel mines were designed and manufactured in the Soviet Union. They are one of the most widely used and commonly found devices during demining operations. They are sometimes nicknamed "black widow" because of their dark casings.

The M15 mine is a large circular United States anti-tank blast mine, first deployed during the Korean War. Essentially, it is a larger version of the M6A2 anti-tank mine, which it replaced. Although the M15 has been superseded by the M19 mine, the U.S. retains large stocks of M15s because they are still regarded as reliable and effective weapons. When used against main battle tanks the M15 is primarily a "track-breaker" which creates mobility kills, but has a comparatively small likelihood of causing crew fatalities. However, when used against lighter vehicles such as APCs or unarmored vehicles such as trucks the damage inflicted is much more severe.

The VS-50 is a circular plastic cased anti-personnel blast mine that entered production in 1985, formerly manufactured by the now-defunct Valsella Meccanotecnica SpA, an Italian high-tech defence industry specialized in area denial systems which was also the manufacturer of the Valmara 69 and one of the first industries in the world to implement plastic construction for landmines. The design is similar to the TS-50 and VS-MK2 mine. It is blast resistant and can be used in a minimum metal configuration. Though unlikely to kill, the explosive charge contained within a VS-50 is quite sufficient to destroy the victim's foot: the blast is capable of penetrating 5 mm of mild steel leaving an 80 mm-diameter hole.

The M7 is a small, metal-cased United States anti-tank blast mine that was used during the Second World War. It was based on the British Hawkins grenade. Approximately 2.5 million were produced before production ceased, and although it has long since been withdrawn from U.S. service, it can be found in Angola, Burma, Cambodia, Chad, Eritrea, Ethiopia, Korea, Lebanon, Myanmar, Somalia, Thailand, and Zambia.

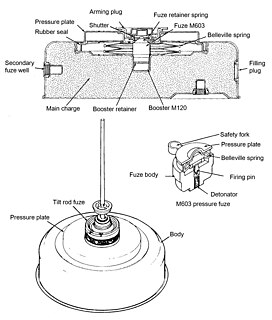

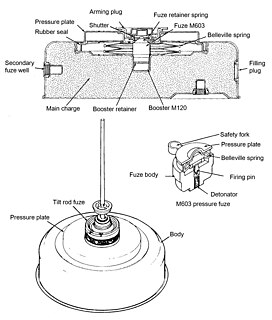

The M21 is a circular United States anti-tank landmine that uses a Misznay Schardin effect warhead. The mine uses an M607 pressure fuse, which can be adapted as a tilt rod fuze. The mine is triggered either by pressure, or by the tilt rod being forced beyond 20 degrees from the vertical by a force of more than 1.7 kg, either of these actions results in pressure being transferred via a bearing cap to a Belleville spring, which inverts, driving the firing pin into the M46 detonator. The M46 charge first ignites a black powder charge, which blows off the mine's cover, and clears any earth or debris that may have been on top of the mine. A fraction of a second later the main warhead detonates, driving and compressing a steel plate upwards, with enough force to penetrate 76 mm of armour at a distance of 530 mm. Approximately 200,000 M21 mines were produced in the U.S. and licensed copies, the K441 and K442, were produced in South Korea.

An anti-handling device is an attachment to or an integral part of a landmine or other munition such as some fuze types found in general-purpose air-dropped bombs, cluster bombs and sea mines. It is designed to prevent tampering or disabling, or to target bomb disposal personnel. When the protected device is disturbed, it detonates, killing or injuring anyone within the blast area. There is a strong functional overlap of booby traps and anti-handling devices.

The FFV 028 is a series of steel cased Swedish anti-tank mines that use electronic fuzes. The mines are circular, with a large Misznay Schardin effect warhead in the center of the mine, with the fuzing and sensor electronics located in the dead space above the main charge. The design of the mine dates from the 1970s and uses a magnetic influence sensor to detonate the mine, making it able to attack the full width of armoured vehicles.

The VS-HCT series of mines are Italian plastic cased anti-tank mines that use Misznay Schardin effect warheads and have a dual seismic and magnetic fuze. The mines are no longer produced and differ in size and shape.

The VAR/40, VAR/100 and VAR/100/SP are Italian anti-personnel blast landmines produced by the Tecnovar italiana S.p.A. company.

The SC 250 was an air-dropped general purpose high-explosive bomb built by Germany during World War II and used extensively during that period. It could be carried by almost all German bomber aircraft, and was used to notable effect by the Junkers Ju 87 Stuka. The bomb's weight was about 250 kg, from which its designation was derived.

A tilt-rod fuze is a device used to trigger anti-vehicle landmines. Typically it consists of a vertical pole, normally around a meter high, which is connected to the top of a landmine. When the track or main body of a vehicle passes over the mine, the rod is tilted, releasing a spring-loaded striker which triggers a pyrotechnic delay of approximately half a second, followed by detonation of the main explosive charge. The small time delay allows the vehicle to continue over the mine before detonating, exposing more of it to the blast. A tilt-rod fuze has a number of advantages over pressure fuzes - it acts across the entire width of a vehicle, rather than just its tracks or tires. This allows it to attack the vehicle's belly and potentially cause a catastrophic kill. Additionally, tilt rod fuzes tend to be resistant to blast overpressure clearing methods, which can trigger most pressure fuzes.

The TMK-2 is a Soviet steel cased anti-tank mine. It uses a tilt-rod fuze combined with a shaped charge to attack the belly of vehicles as they pass over the mine. It was originally designed in 1955, but is now obsolete. The mine consists of a case shaped like two truncated cones joined at the base. The MVK-2 tilt rod assembly is held to one side of the mine. The lower truncated cone contains the main charge, and dished metal charge liner.

In military munitions, a fuze is the part of the device that initiates function. In some applications, such as torpedoes, a fuze may be identified by function as the exploder. The relative complexity of even the earliest fuze designs can be seen in cutaway diagrams.