Liquefied petroleum gas is a fuel gas which contains a flammable mixture of hydrocarbon gases, specifically propane, propylene, butylene, isobutane, and n-butane.

A diving cylinder or diving gas cylinder is a gas cylinder used to store and transport high pressure gas used in diving operations. This may be breathing gas used with a scuba set, in which case the cylinder may also be referred to as a scuba cylinder, scuba tank or diving tank. When used for an emergency gas supply for surface supplied diving or scuba, it may be referred to as a bailout cylinder or bailout bottle. It may also be used for surface-supplied diving or as decompression gas. A diving cylinder may also be used to supply inflation gas for a dry suit or buoyancy compensator. Cylinders provide gas to the diver through the demand valve of a diving regulator or the breathing loop of a diving rebreather.

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.

A gas cylinder is a pressure vessel for storage and containment of gases at above atmospheric pressure. High-pressure gas cylinders are also called bottles. Inside the cylinder the stored contents may be in a state of compressed gas, vapor over liquid, supercritical fluid, or dissolved in a substrate material, depending on the physical characteristics of the contents. A typical gas cylinder design is elongated, standing upright on a flattened bottom end, with the valve and fitting at the top for connecting to the receiving apparatus.

Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurized according to the resistance present. The fluid is controlled directly or automatically by control valves and distributed through hoses, tubes, or pipes.

A compression fitting is a fitting used in plumbing and electrical conduit systems to join two tubes or thin-walled pipes together. In instances where two pipes made of dissimilar materials are to be joined, the fittings will be made of one or more compatible materials appropriate for the connection. Compression fittings for attaching tubing (piping) commonly have ferrules in them, and are sometimes referred to as flareless fittings. There are also flare fittings that do not require ferrules/olives.

A collet is a segmented sleeve, band or collar. One of the two radial surfaces of a collet is usually tapered and the other is cylindrical. The term collet commonly refers to a type of chuck that uses collets to hold either a workpiece or a tool but has other mechanical applications.

In plumbing and piping, a nipple is a fitting, consisting of a short piece of pipe, usually provided with a male pipe thread at each end, for connecting two other fittings.

A hose coupling is a connector on the end of a hose to connect it with another hose or with a tap or a hose appliance, such as an irrigation sprinkler. It is usually made of steel, brass, stainless steel, aluminium or plastic.

Flare fittings are a type of compression fitting used with metal tubing, usually soft steel, ductile (soft) copper and aluminum, though other materials are also used. In a flare fitting the tube itself is "flared" i.e. expanded and deformed at the end. The flare is then pressed against the fitting it connects to and is secured by a close-fitting nut that ensures that no leakage happens. Tube flaring is a type of forging operation, and is usually a cold working procedure. During assembly, a flare nut is used to secure the flared tubing's tapered end to the also tapered fitting, producing a pressure-resistant, leak-tight seal. Flared connections offer a high degree of long-term reliability and for this reason are often used in mission-critical and inaccessible locations.

The Compressed Gas Association (CGA) is an American trade association for the industrial and medical gas supply industries.

A scuba manifold is a device incorporating one or more valves and one or more gas outlets with scuba regulator connections, used to connect two or more diving cylinders containing breathing gas, providing a greater amount of gas for longer dive times or deeper dives. An isolation manifold allows the connection between the cylinders to be closed in the case of a leak from one of the cylinders or its valve or regulator, conserving the gas in the other cylinder. Diving with two or more cylinders is often associated with technical diving. Almost all manifold assemblies include one cylinder valve for each cylinder, and the overwhelming majority are for two cylinders.

The Pin Index Safety System (PISS) is a means of connecting high pressure cylinders containing medical gases to a regulator or other utilization equipment. It uses geometric features on the valve and yoke to prevent mistaken use of the wrong gas. This system is widely used worldwide for anesthesia machines, portable oxygen administration sets, and inflation gases used in surgery.

A fitting or adapter is used in pipe systems to connect straight sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating fluid flow. These fittings are used in plumbing to manipulate the conveyance of water, gas, or liquid waste in domestic or commercial environments, within a system of pipes or tubes.

A cam and groove coupling, also called a camlock fitting, is a form of hose coupling. This kind of coupling is popular because it is a simple and reliable means of connecting and disconnecting hoses quickly and without tools.

A gas cabinet is a metallic enclosure which is used to provide local exhaust ventilation system for virtually all of the gases used or generated in the semiconductor, solar, MEMS, NANO, solar PV, manufacturing and other advanced technologies.

Transportable pressure vessels for high-pressure gases are routinely inspected and tested as part of the manufacturing process. They are generally marked as evidence of passing the tests, either individually or as part of a batch, and certified as meeting the standard of manufacture by the authorised testing agency, making them legal for import and sale. When a cylinder is manufactured, its specification, including manufacturer, working pressure, test pressure, date of manufacture, capacity and weight are stamped on the cylinder.

Several types of valve connections for propane, butane, and LPG containers exist for transport and storage, sometimes with overlapping usage and applications, and there are major differences in usage between different countries. Even within a single country more than one type can be in use for a specific application. This requires adequate tooling and adapters for replenishment in multiple countries. For example for overlanders and users of autogas traveling with a container originating in one country to other parts of the world this is a major concern. This article describes existing standards and the standards in use for a number of countries. For disposable containers the availability per country is described. Filling stations may be able and allowed to fill foreign containers if adequate adapters are available. Adapters are provided by, amongst others, camping stores. The iOverlander database maintained by travelers, My LPG and the Facebook group "Cooking Gas Around the World" provide more information about individual sources per country. Much general information about global LPG use and standardization is available from the World LPG Association and the AEGPL

A scuba cylinder valve or pillar valve is a high pressure manually operated screw-down shut off valve fitted to the neck of a scuba cylinder to control breathing gas flow to and from the pressure vessel and to provide a connection with the scuba regulator or filling whip. Cylinder valves are usually machined from brass and finished with a protective and decorative layer of chrome plating. A metal or plastic dip tube or valve snorkel screwed into the bottom of the valve extends into the cylinder to reduce the risk of liquid or particulate contaminants in the cylinder getting into the gas passages when the cylinder is inverted, and blocking or jamming the regulator.

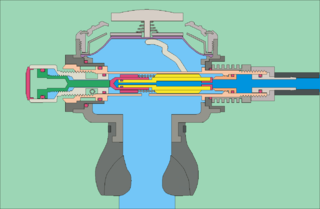

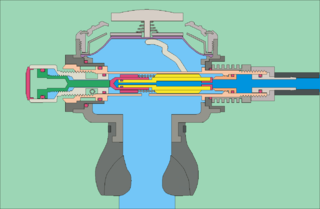

The mechanism of diving regulators is the arrangement of components and function of gas pressure regulators used in the systems which supply breathing gases for underwater diving. Both free-flow and demand regulators use mechanical feedback of the downstream pressure to control the opening of a valve which controls gas flow from the upstream, high-pressure side, to the downstream, low-pressure side of each stage. Flow capacity must be sufficient to allow the downstream pressure to be maintained at maximum demand, and sensitivity must be appropriate to deliver maximum required flow rate with a small variation in downstream pressure, and for a large variation in supply pressure, without instability of flow. Open circuit scuba regulators must also deliver against a variable ambient pressure. They must be robust and reliable, as they are life-support equipment which must function in the relatively hostile seawater environment, and the human interface must be comfortable over periods of several hours.