A flange is a protruded ridge, lip or rim, either external or internal, that serves to increase strength ; for easy attachment/transfer of contact force with another object ; or for stabilizing and guiding the movements of a machine or its parts. The term "flange" is also used for a kind of tool used to form flanges.

In metalworking and jewelry making, casting is a process in which a liquid metal is delivered into a mold that contains a negative impression of the intended shape. The metal is poured into the mold through a hollow channel called a sprue. The metal and mold are then cooled, and the metal part is extracted. Casting is most often used for making complex shapes that would be difficult or uneconomical to make by other methods.

An engineering drawing is a type of technical drawing that is used to convey information about an object. A common use is to specify the geometry necessary for the construction of a component and is called a detail drawing. Usually, a number of drawings are necessary to completely specify even a simple component. The drawings are linked together by a master drawing or assembly drawing which gives the drawing numbers of the subsequent detailed components, quantities required, construction materials and possibly 3D images that can be used to locate individual items. Although mostly consisting of pictographic representations, abbreviations and symbols are used for brevity and additional textual explanations may also be provided to convey the necessary information.

A boiler is a closed vessel in which fluid is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.

Geometric Dimensioning and Tolerancing (GD&T) is a system for defining and communicating engineering tolerances. It uses a symbolic language on engineering drawings and computer-generated three-dimensional solid models that explicitly describe nominal geometry and its allowable variation. It tells the manufacturing staff and machines what degree of accuracy and precision is needed on each controlled feature of the part. GD&T is used to define the nominal geometry of parts and assemblies, to define the allowable variation in form and possible size of individual features, and to define the allowable variation between features.

The American Society of Mechanical Engineers (ASME) is an American professional association that, in its own words, "promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe" via "continuing education, training and professional development, codes and standards, research, conferences and publications, government relations, and other forms of outreach." ASME is thus an engineering society, a standards organization, a research and development organization, an advocacy organization, a provider of training and education, and a nonprofit organization. Founded as an engineering society focused on mechanical engineering in North America, ASME is today multidisciplinary and global.

Within industry, piping is a system of pipes used to convey fluids from one location to another. The engineering discipline of piping design studies the efficient transport of fluid.

Adrian Bejan is a Romanian-American professor who has made contributions to modern thermodynamics and developed his constructal law. He is J. A. Jones Distinguished Professor of Mechanical Engineering at Duke University and author of the books The Physics of Life: The Evolution of Everything and Freedom and Evolution: Hierarchy in Nature, Society and Science.

Compression molding is a method of molding in which the molding material, generally preheated, is first placed in an open, heated mold cavity. The mold is closed with a top force or plug member, pressure is applied to force the material into contact with all mold areas, while heat and pressure are maintained until the molding material has cured; this process is known as compression molding method and in case of rubber it is also known as 'Vulcanisation'. The process employs thermosetting resins in a partially cured stage, either in the form of granules, putty-like masses, or preforms.

Lost-foam casting (LFC) is a type of evaporative-pattern casting process that is similar to investment casting except foam is used for the pattern instead of wax. This process takes advantage of the low boiling point of polymer foams to simplify the investment casting process by removing the need to melt the wax out of the mold.

John Edson Sweet was an American mechanical engineer, inventor, professor, businessman and president of the American Society of Mechanical Engineers from 1884-1885. He is known for building the first micrometer caliper in 1873, for making tools, and for inventing the “straight line” engine.

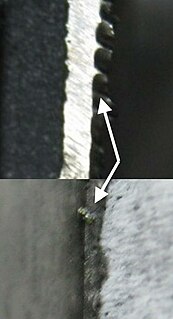

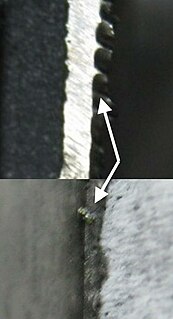

A burr is a raised edge or small piece of material that remains attached to a workpiece after a modification process.

Flash, also known as flashing, is excess material attached to a molded, forged, or cast product, which must usually be removed. This is typically caused by leakage of the material between the two surfaces of a mold or between the base material and the mold in the case of overmolding.

In engineering, draft is the amount of taper for molded or cast parts perpendicular to the parting line. It can be measured in degrees or mm/mm (in/in).

Full-mold casting is an evaporative-pattern casting process which is a combination of sand casting and lost-foam casting. It uses an expanded polystyrene foam pattern which is then surrounded by sand, much like sand casting. The metal is then poured directly into the mold, which vaporizes the foam upon contact.

Cryogenic deflashing is a deflashing process that uses cryogenic temperatures to aid in the removal of flash on cast or molded workpieces. These temperatures cause the flash to become stiff or brittle and to break away cleanly. Cryogenic deflashing is the preferred process when removing excess material from oddly shaped, custom molded products.

Engineering drawing abbreviations and symbols are used to communicate and detail the characteristics of an engineering drawing. This list includes abbreviations common to the vocabulary of people who work with engineering drawings in the manufacture and inspection of parts and assemblies.

Plaster mold casting is a metalworking casting process similar to sand casting except the molding material is plaster of Paris instead of sand. Like sand casting, plaster mold casting is an expendable mold process, however it can only be used with non-ferrous materials. It is used for castings as small as 30 g (1 oz) to as large as 7–10 kg (15–22 lb). Generally, the form takes less than a week to prepare. Production rates of 1–10 units/hr can be achieved with plaster molds.

A liquid nitrogen vehicle is powered by liquid nitrogen, which is stored in a tank. Traditional nitrogen engine designs work by heating the liquid nitrogen in a heat exchanger, extracting heat from the ambient air and using the resulting pressurized gas to operate a piston or rotary motor. Vehicles propelled by liquid nitrogen have been demonstrated, but are not used commercially. One such vehicle, Liquid Air was demonstrated in 1902.

Laser ignition is an alternative method for igniting mixtures of fuel and oxidiser. The phase of the mixture can be gaseous or liquid. The method is based on laser ignition devices that produce short but powerful flashes regardless of the pressure in the combustion chamber. Usually, high voltage spark plugs are good enough for automotive use, as the typical compression ratio of an Otto cycle internal combustion engine is around 10:1 and in some rare cases reach 14:1. However, fuels such as natural gas or methanol can withstand high compression without self ignition. This allows higher compression ratios, because it is economically reasonable, as the fuel efficiency of such engines is high. Using high compression ratio and high pressure requires special spark plugs that are expensive and their electrodes still wear out. Thus, even expensive laser ignition systems could be economical, because they would last longer.