Polyurethane refers to a class of polymers composed of organic units joined by carbamate (urethane) links. In contrast to other common polymers such as polyethylene and polystyrene, polyurethane is produced from a wide range of starting materials. This chemical variety produces polyurethanes with different chemical structures leading to many different applications. These include rigid and flexible foams, and coatings, adhesives, electrical potting compounds, and fibers such as spandex and polyurethane laminate (PUL). Foams are the largest application accounting for 67% of all polyurethane produced in 2016.

Epoxy is the family of basic components or cured end products of epoxy resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also collectively called epoxy. The IUPAC name for an epoxide group is an oxirane.

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening ("curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and may be promoted by high pressure or mixing with a catalyst. Heat is not necessarily applied externally, and is often generated by the reaction of the resin with a curing agent. Curing results in chemical reactions that create extensive cross-linking between polymer chains to produce an infusible and insoluble polymer network.

In organic chemistry, a polyol is an organic compound containing multiple hydroxyl groups. The term "polyol" can have slightly different meanings depending on whether it is used in food science or polymer chemistry. Polyols containing two, three and four hydroxyl groups are diols, triols, and tetrols, respectively.

Gelcoat or gel coat is a material used to provide a high-quality finish on the visible surface of a fibre-reinforced composite. The most common gelcoats are thermosetting polymers based on epoxy or unsaturated polyester resin chemistry. Gelcoats are modified resins which are applied to moulds in the liquid state. They are cured to form crosslinked polymers and are subsequently backed with thermoset polymer matrix composites which are often mixtures of polyester resin and fiberglass, or epoxy resin which is most commonly used with carbon fibre for higher specific strength.

Teijin Limited is a Japanese chemical, pharmaceutical and information technology company. Its main fields of operation are high-performance fibers such as aramid, carbon fibers & composites, healthcare, films, resin & plastic processing, polyester fibers, products converting and IT products.

Powder coating is a type of coating that is applied as a free-flowing, dry powder. Unlike conventional liquid paint, which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light. The powder may be a thermoplastic or a thermoset polymer. It is usually used to create a thick, tough finish that is more durable than conventional paint. Powder coating is mainly used for coating of metal objects, particularly those subject to rough use. Advancements in powder coating technology like UV-curable powder coatings allow for other materials such as plastics, composites, carbon fiber, and MDF to be powder coated, as little heat or oven dwell time is required to process them.

Vinyl ester resin, or often just vinyl ester, is a resin produced by the esterification of an epoxy resin with acrylic or methacrylic acids. The "vinyl" groups refer to these ester substituents, which are prone to polymerize and thus an inhibitor is usually added. The diester product is then dissolved in a reactive solvent, such as styrene, to approximately 35–45 percent content by weight. Polymerization is initiated by free radicals, which are generated by UV-irradiation or peroxides.

Polyester is a category of polymers that contain the ester functional group in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include naturally occurring chemicals, such as in plants and insects, as well as synthetics such as polybutyrate. Natural polyesters and a few synthetic ones are biodegradable, but most synthetic polyesters are not. Synthetic polyesters are used extensively in clothing.

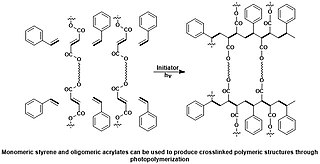

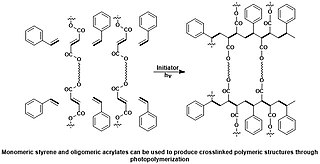

A photopolymer or light-activated resin is a polymer that changes its properties when exposed to light, often in the ultraviolet or visible region of the electromagnetic spectrum. These changes are often manifested structurally, for example hardening of the material occurs as a result of cross-linking when exposed to light. An example is shown below depicting a mixture of monomers, oligomers, and photoinitiators that conform into a hardened polymeric material through a process called curing.

Pultrusion is a continuous process for manufacture of fibre-reinforced plastics with constant cross-section. The term is a portmanteau word, combining "pull" and "extrusion". As opposed to extrusion, which pushes the material, pultrusion pulls the material.

Polyester resins are synthetic resins formed by the reaction of dibasic organic acids and polyhydric alcohols. Maleic anhydride is a commonly used raw material with diacid functionality in unsaturated polyester resins. Unsaturated polyester resins are used in sheet moulding compound, bulk moulding compound and the toner of laser printers. Wall panels fabricated from polyester resins reinforced with fiberglass—so-called fiberglass reinforced plastic (FRP)—are typically used in restaurants, kitchens, restrooms and other areas that require washable low-maintenance walls. They are also used extensively in cured-in-place pipe applications. Departments of Transportation in the USA also specify them for use as overlays on roads and bridges. In this application they are known AS Polyester Concrete Overlays (PCO). These are usually based on isophthalic acid and cut with styrene at high levels—usually up to 50%. Polyesters are also used in anchor bolt adhesives though epoxy based materials are also used. Many companies have and continue to introduce styrene free systems mainly due to odor issues, but also over concerns that styrene is a potential carcinogen. Drinking water applications also prefer styrene free. Most polyester resins are viscous, pale coloured liquids consisting of a solution of a polyester in a reactive diluent which is usually styrene, but can also include vinyl toluene and various acrylates.

Sheet moulding compound (SMC) or sheet moulding composite is a ready to mould glass-fibre reinforced polyester material primarily used in compression moulding. The sheet is provided in rolls weighing up to 1000 kg. Alternatively the resin and related materials may be mixed on site when a producer wants greater control over the chemistry and filler.

Epoxy granite, also known as synthetic granite, is a polymer matrix composite and is a mixture of epoxy and granite commonly used as an alternative material for machine tool bases. Epoxy granite is used instead of cast iron and steel for improved vibration damping, longer tool life, and lower assembly cost, and thus better properties for stabilizing and housing machines.

A thermoset polymer matrix is a synthetic polymer reinforcement where polymers act as binder or matrix to secure in place incorporated particulates, fibres or other reinforcements. They were first developed for structural applications, such as glass-reinforced plastic radar domes on aircraft and graphite-epoxy payload bay doors on the Space Shuttle.

Carbon fiber-reinforced polymers, carbon-fibre-reinforced polymers, carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic, also known as carbon fiber, carbon composite, or just carbon, are extremely strong and light fiber-reinforced plastics that contain carbon fibers. CFRPs can be expensive to produce, but are commonly used wherever high strength-to-weight ratio and stiffness (rigidity) are required, such as aerospace, superstructures of ships, automotive, civil engineering, sports equipment, and an increasing number of consumer and technical applications.

In polymer chemistry, the term prepolymer or pre-polymer, refers to a monomer or system of monomers that have been reacted to an intermediate-molecular mass state. This material is capable of further polymerization by reactive groups to a fully cured, high-molecular-mass state. As such, mixtures of reactive polymers with un-reacted monomers may also be referred to as pre-polymers. The term "pre-polymer" and "polymer precursor" may be interchanged.

Zyvex Technologies is a molecular engineering company headquartered in Columbus, Ohio. Zyvex Technologies focuses on developing advanced materials, including prepreg, epoxy resins, and adhesives.

The wet strength of paper and paperboard is a measure of how well the web of fibers holding the paper together can resist a force of rupture when the paper is wet. Wet strength is routinely expressed as the ratio of wet to dry tensile force at break.

Glass-filled polymer, is a mouldable composite material. It comprises short glass fibers in a matrix of a polymer material. It is used to manufacture a wide range of structural components by injection or compression moulding. It is an ideal glass alternative that offers flexibility in the part, chemical resistance, shatter resistance and overall better durability.