Related Research Articles

The technical meaning of maintenance involves functional checks, servicing, repairing or replacing of necessary devices, equipment, machinery, building infrastructure, and supporting utilities in industrial, business, and residential installations. Over time, this has come to include multiple wordings that describe various cost-effective practices to keep equipment operational; these activities occur either before or after a failure.

A power take-off or power takeoff (PTO) is one of several methods for taking power from a power source, such as a running engine, and transmitting it to an application such as an attached implement or separate machine.

An inspection is, most generally, an organized examination or formal evaluation exercise. In engineering activities inspection involves the measurements, tests, and gauges applied to certain characteristics in regard to an object or activity. The results are usually compared to specified requirements and standards for determining whether the item or activity is in line with these targets, often with a Standard Inspection Procedure in place to ensure consistent checking. Inspections are usually non-destructive.

Professional diving is underwater diving where the divers are paid for their work. The procedures are often regulated by legislation and codes of practice as it is an inherently hazardous occupation and the diver works as a member of a team. Due to the dangerous nature of some professional diving operations, specialized equipment such as an on-site hyperbaric chamber and diver-to-surface communication system is often required by law, and the mode of diving for some applications may be regulated.

The Driver and Mechanic Badge is a military special skill badge of the United States Army which was first created in July 1942. The badge is awarded to drivers, mechanics, and special equipment operators to denote the attainment of a high degree of skill in the operation and maintenance of motor vehicles. The badge was originally referred to as the “Motor Vehicle Badge” and adopted its current title of Driver and Mechanic Badge during the Korean War.

A feller buncher is a type of harvester used in logging. It is a motorized vehicle with an attachment that can rapidly gather and cut a tree before felling it.

An aerial work platform (AWP), also known as an aerial device, elevating work platform (EWP), cherry picker, bucket truck or mobile elevating work platform (MEWP) is a mechanical device used to provide temporary access for people or equipment to inaccessible areas, usually at height. There are distinct types of mechanized access platforms and the individual types may also be known as a "cherry picker", "boom lift" or "scissor lift".

In the US, an aircraft maintenance technician (AMT) is a tradesperson and also refers to a licensed technical qualification for carrying out aircraft maintenance. AMTs inspect and perform or supervise maintenance, preventive maintenance, repairs and alteration of aircraft and aircraft systems.

The MOT test is an annual test of vehicle safety, roadworthiness aspects and exhaust emissions required in the United Kingdom for most vehicles over three years old. In Northern Ireland the equivalent requirement applies after four years. The requirement does not apply to vehicles used only on various small islands with no convenient connection "to a road in any part of Great Britain"; no similar exemption is listed at the beginning of 2014 for Northern Ireland, which has a single inhabited island, Rathlin. The MOT test was first introduced in 1960 as a few basic tests of a vehicle and now covers twenty different parts or systems on or in the car.

Historically, an armourer is a person who makes personal armour, especially plate armour.

An auto mechanic is a mechanic who services and repairs automobiles, sometimes specializing in one or more automobile brands or sometimes working with any brand. In fixing cars, their main role is to diagnose and repair the problem accurately and quickly. Seasoned auto repair shops start with a (Digital) Inspection to determine the vehicle conditions, independent of the customers concern. Based on the concern, the inspection results and preventative maintenance needs, the mechanic/technician returns the findings to the service advisor who then gets approval for any or all of the proposed work. The approved work will be assigned to the mechanic on a work order. Their work may involve the repair of a specific part or the replacement of one or more parts as assemblies. Basic vehicle maintenance is a fundamental part of a mechanic's work in modern industrialized countries, while in others they are only consulted when a vehicle is already showing signs of malfunction.

Predictive maintenance techniques are designed to help determine the condition of in-service equipment in order to estimate when maintenance should be performed. This approach promises cost savings over routine or time-based preventive maintenance, because tasks are performed only when warranted. Thus, it is regarded as condition-based maintenance carried out as suggested by estimations of the degradation state of an item.

The M9 Armored Combat Earthmover (ACE) is a highly mobile armored tracked vehicle that provides combat engineer support to front-line forces. Fielded by the United States Army, its tasks include eliminating enemy obstacles, maintenance and repair of roads and supply routes, and construction of fighting positions.

Reliability-centered maintenance (RCM) is a concept of maintenance planning to ensure that systems continue to do what their user require in their present operating context. Successful implementation of RCM will lead to increase in cost effectiveness, reliability, machine uptime, and a greater understanding of the level of risk that the organization is managing.

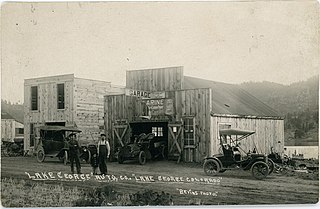

An automobile repair shop is an establishment where automobiles are repaired by auto mechanics and technicians. The customer interface is typically a service advisor, traditionally called a service writer.

Aircraft maintenance is the performance of tasks required to ensure the continuing airworthiness of an aircraft or aircraft part, including overhaul, inspection, replacement, defect rectification, and the embodiment of modifications, compliance with airworthiness directives and repair.

Material handling equipment (MHE) is mechanical equipment used for the movement, storage, control, and protection of materials, goods and products throughout the process of manufacturing, distribution, consumption, and disposal. The different types of equipment can be classified into four major categories: transport equipment, positioning equipment, unit load formation equipment, and storage equipment.

Equipment rental, also called plant hire in some countries, is a service industry providing machinery, equipment and tools of all kinds and sizes for a limited period of time to final users, mainly to construction contractors but also to industry and individual consumers. Renting can be defined as paying someone for the use of something for temporary or short-term purposes.

Operational maintenance is the care and minor maintenance of equipment using procedures that do not require detailed technical knowledge of the equipment’s or system’s function and design. This category of operational maintenance normally consists of inspecting, cleaning, servicing, preserving, lubricating, and adjusting, as required. Such maintenance may also include minor parts replacement that does not require the person performing the work to have highly technical skills or to perform internal alignment.

Workplace robotics safety is an aspect of occupational safety and health when robots are used in the workplace. This includes traditional industrial robots as well as emerging technologies such as drone aircraft and wearable robotic exoskeletons. Types of accidents include collisions, crushing, and injuries from mechanical parts. Hazard controls include physical barriers, good work practices, and proper maintenance.