Related Research Articles

Amine gas treating, also known as amine scrubbing, gas sweetening and acid gas removal, refers to a group of processes that use aqueous solutions of various alkylamines (commonly referred to simply as amines) to remove hydrogen sulfide (H2S) and carbon dioxide (CO2) from gases. It is a common unit process used in refineries, and is also used in petrochemical plants, natural gas processing plants and other industries.

JMP is a suite of computer programs for statistical analysis and machine learning developed by JMP, a subsidiary of SAS Institute. The program was launched in 1989 to take advantage of the graphical user interface introduced by the Macintosh operating systems. It has since been significantly rewritten and made available for the Windows operating system.

Ansys, Inc. is an American multinational company with its headquarters based in Canonsburg, Pennsylvania. It develops and markets CAE/multiphysics engineering simulation software for product design, testing and operation and offers its products and services to customers worldwide.

A process flow diagram (PFD) is a diagram commonly used in chemical and process engineering to indicate the general flow of plant processes and equipment. The PFD displays the relationship between major equipment of a plant facility and does not show minor details such as piping details and designations. Another commonly used term for a PFD is processflowsheet. It is the key document in process design.

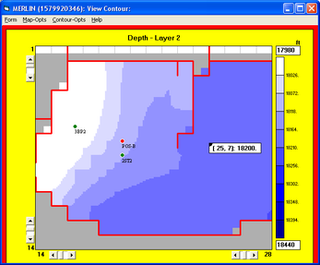

Reservoir simulation is an area of reservoir engineering in which computer models are used to predict the flow of fluids through porous media.

Natural-gas processing is a range of industrial processes designed to purify raw natural gas by removing contaminants such as solids, water, carbon dioxide (CO2), hydrogen sulfide (H2S), mercury and higher molecular mass hydrocarbons (condensate) to produce pipeline quality dry natural gas for pipeline distribution and final use. Some of the substances which contaminate natural gas have economic value and are further processed or sold. Hydrocarbons that are liquid at ambient conditions: temperature and pressure (i.e., pentane and heavier) are called natural-gas condensate (sometimes also called natural gasoline or simply condensate).

Selexol is the trade name for an acid gas removal solvent that can separate acid gases such as hydrogen sulfide and carbon dioxide from feed gas streams such as synthesis gas produced by gasification of coal, coke, or heavy hydrocarbon oils. By doing so, the feed gas is made more suitable for combustion and/or further processing. It is made up of dimethyl ethers of polyethylene glycol.

The COCO Simulator is a free-of-charge, non-commercial, graphical, modular and CAPE-OPEN compliant, steady-state, sequential simulation process modeling environment. It was originally intended as a test environment for CAPE-OPEN modeling tools but now provides free chemical process simulation for students. It is an open flowsheet modeling environment allowing anyone to add new unit operations or thermodynamics packages.

Simulation software is based on the process of modeling a real phenomenon with a set of mathematical formulas. It is, essentially, a program that allows the user to observe an operation through simulation without actually performing that operation. Simulation software is used widely to design equipment so that the final product will be as close to design specs as possible without expensive in process modification. Simulation software with real-time response is often used in gaming, but it also has important industrial applications. When the penalty for improper operation is costly, such as airplane pilots, nuclear power plant operators, or chemical plant operators, a mock up of the actual control panel is connected to a real-time simulation of the physical response, giving valuable training experience without fear of a disastrous outcome.

Symbolic Analysis Program for Windows (SAPWIN) is a proprietary symbolic circuit simulator written in C++ for the Microsoft Windows operating systems Vista, 7.0 and 8.1. Unlike more common numerical circuit simulators, SAPWIN can generate analytical Laplace domain expressions for arbitrary network functions of linear analog circuits. The SAPWIN package also includes tools for schematic capture and graphic post-processing.

SimulationX is a CAE software application running on Microsoft Windows for the physical simulation of technical systems. It is developed and sold by ESI Group.

Crosslight Software Inc. is an international company headquartered in greater Vancouver, British Columbia, Canada. Officially spun off from the National Research Council of Canada (NRC) in 1995, it provides Technology Computer Aided Design (TCAD) tools for semiconductor device and process simulations.

EMSO simulator is an equation-oriented process simulator with a graphical interface for modeling complex dynamic or steady-state processes. It is CAPE-OPEN compliant. EMSO stands for Environment for Modeling, Simulation, and Optimization. The ALSOC Project - a Portuguese acronym for Free Environment for Simulation, Optimization and Control of Processes -, which is based at the UFRGS, develops, maintains and distributes this object-oriented software. Pre-built models are available in the EMSO Modeling Library (EML). New models can be written in the EMSO modeling language or a user can embed models coded in C, C++ or Fortran into the simulation environment.

Reaction Design is a San Diego-based developer of combustion simulation software used by engineers to design cleaner burning and fuel-efficient combustors and engines, found in everything from automobiles to turbines for power generation and aircraft propulsion to large diesel engines that use pistons the size of rooms to propel ships locomotives. The technology is also used to model spray vaporization in electronic materials processing applications and predict mixing reactions in chemical plants. Ansys, a leader in engineering simulation software, acquired Reaction Design in January 2014.

20-sim is a commercial modeling and simulation program for multi-domain dynamic systems, which is developed by Controllab. With 20-sim, models can be entered as equations, block diagrams, bond graphs and physical components. 20-sim is used for modeling complex multi-domain systems and for the development of control systems.

Simcenter Amesim is a commercial simulation software for the modeling and analysis of multi-domain systems. It is part of systems engineering domain and falls into the mechatronic engineering field.

Aspen Plus, Aspen HYSYS, ChemCad and MATLAB, PRO are the commonly used process simulators for modeling, simulation and optimization of a distillation process in the chemical industries. Distillation is the technique of preferential separation of the more volatile components from the less volatile ones in a feed followed by condensation. The vapor produced is richer in the more volatile components. The distribution of the component in the two phase is governed by the vapour-liquid equilibrium relationship. In practice, distillation may be carried out by either two principal methods. The first method is based on the production of vapor boiling the liquid mixture to be separated and condensing the vapors without allowing any liquid to return to the still. There is no reflux. The second method is based on the return of part of the condensate to still under such conditions that this returning liquid is brought into intimate contact with the vapors on their way to condenser.

The CAPE-OPEN Interface Standard consists of a series of specifications to expand the range of application of process simulation technologies. The CAPE-OPEN specifications define a set of software interfaces that allow plug and play inter-operability between a given Process Modelling Environment and a third-party Process Modelling Component.

References

- ↑ "AspenTech Press Release". Archived from the original on 2007-10-11. Retrieved 2007-12-21.

- ↑ BR&E Material Archived 2007-08-31 at the Wayback Machine