Recycling is the process of converting waste materials into new materials and objects. This concept often includes the recovery of energy from waste materials. The recyclability of a material depends on its ability to reacquire the properties it had in its original state. It is an alternative to "conventional" waste disposal that can save material and help lower greenhouse gas emissions. It can also prevent the waste of potentially useful materials and reduce the consumption of fresh raw materials, reducing energy use, air pollution and water pollution.

Product stewardship is an approach to managing the environmental impacts of different products and materials and at different stages in their production, use and disposal. It acknowledges that those involved in producing, selling, using and disposing of products have a shared responsibility to ensure that those products or materials are managed in a way that reduces their impact, throughout their lifecycle, on the environment and on human health and safety. This approach focusses on the product itself, and everyone involved in the lifespan of the product is called upon to take up responsibility to reduce its environmental, health, and safety impacts.

The Waste Electrical and Electronic Equipment Directive is a European Community Directive, numbered 2012/19/EU, concerned with waste electrical and electronic equipment (WEEE). Together with the RoHS Directive 2011/65/EU, it became European Law in February 2003. The WEEE Directive set collection, recycling and recovery targets for all types of electrical goods, with a minimum rate of 4 kilograms (9 lb) per head of population per annum recovered for recycling by 2009. The RoHS Directive set restrictions upon European manufacturers as to the material content of new electronic equipment placed on the market.

Extended producer responsibility (EPR) is a strategy to add all of the estimated environmental costs associated with a product throughout the product life cycle to the market price of that product, contemporarily mainly applied in the field of waste management. Such societal costs are typically externalities to market mechanisms, with a common example being the impact of cars.

Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) is a European Union regulation dating from 18 December 2006. REACH addresses the production and use of chemical substances, and their potential impacts on both human health and the environment. Its 849 pages took seven years to pass, and it has been described as the most complex legislation in the Union's history and the most important in 20 years. It is the strictest law to date regulating chemical substances and will affect industries throughout the world. REACH entered into force on 1 June 2007, with a phased implementation over the next decade. The regulation also established the European Chemicals Agency, which manages the technical, scientific and administrative aspects of REACH.

Electronic waste recycling, electronics recycling, or e-waste recycling is the disassembly and separation of components and raw materials of waste electronics; when referring to specific types of e-waste, the terms like computer recycling or mobile phone recycling may be used. Like other waste streams, reuse, donation, and repair are common sustainable ways to dispose of IT waste.

An Electronic Waste Recycling Fee is a fee imposed by government on new purchases of electronic products. The fees are used to pay for the future recycling of these products, as many contain hazardous materials. Locations that have such fees include the European Union, the US State of California and the province of Ontario, Canada.

Reuse is the action or practice of using an item, whether for its original purpose or to fulfill a different function. It should be distinguished from recycling, which is the breaking down of used items to make raw materials for the manufacture of new products. Reuse—by taking, but not reprocessing, previously used items—helps save time, money, energy and resources. In broader economic terms, it can make quality products available to people and organizations with limited means, while generating jobs and business activity that contribute to the economy.

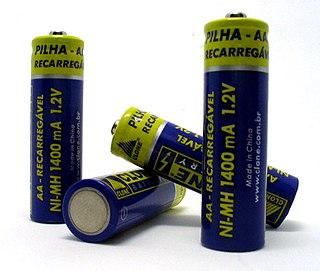

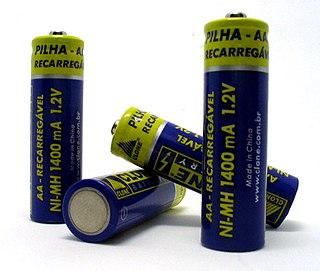

The Directive 2006/66/EC of the European Parliament and of the Council of 6 September 2006 on batteries and accumulators and waste batteries and accumulators and repealing Directive 91/157/EEC, commonly known as the Battery Directive, regulates the manufacture and disposal of batteries in the European Union with the aim of "improving the environmental performance of batteries and accumulators".

In 2015, 43.5% of the United Kingdom's municipal waste was recycled, composted or broken down by anaerobic digestion. The majority of recycling undertaken in the United Kingdom is done by statutory authorities, although commercial and industrial waste is chiefly processed by private companies. Local Authorities are responsible for the collection of municipal waste and operate contracts which are usually kerbside collection schemes. The Household Waste Recycling Act 2003 required local authorities in England to provide every household with a separate collection of at least two types of recyclable materials by 2010. Recycling policy is devolved to the administrations of Scotland, Northern Ireland and Wales who set their own targets, but all statistics are reported to Eurostat.

The Green Dot is the financing symbol of a European network of industry-funded systems for recycling the packaging materials of consumer goods. The logo is a trademark protected worldwide—it is not a recycling logo.

The End of Life Vehicles Directive is a Directive of the European Union addressing the end of life for automotive products. Every year, motor vehicles which have reached the end of their useful lives create between 8 and 9 million tonnes of waste in the European Union. In 1997, the European Commission adopted a Proposal for a Directive to tackle this problem.

In a similar vein to packaging, electronic equipment and vehicles, the concept of extended producer responsibility was applied to battery regulations in the UK through the transposition of the EU Battery Directive into UK legislation. The Directive required member states to have put regulations in place by 26 September 2008. Although the UK managed to introduce the single market requirements by that date, they failed to implement the collection and recycling requirements. Following a consultation, the government laid the new Regulations before Parliament on 16 April 2009, which came into force on 5 May 2009. Responsibility for the financing of waste battery collection and treatment was applied to producers from 1 January 2010, whilst retailers were obliged to offer free take back of portable batteries to consumers from 1 February 2010.

Electronic waste is a significant part of today's global, post-consumer waste stream. Efforts are being made to recycle and reduce this waste.

Waste management laws govern the transport, treatment, storage, and disposal of all manner of waste, including municipal solid waste, hazardous waste, and nuclear waste, among many other types. Waste laws are generally designed to minimize or eliminate the uncontrolled dispersal of waste materials into the environment in a manner that may cause ecological or biological harm, and include laws designed to reduce the generation of waste and promote or mandate waste recycling. Regulatory efforts include identifying and categorizing waste types and mandating transport, treatment, storage, and disposal practices.

A Packaging Recovery Note (PRN) is a type of document that provides evidence waste packaging material has been recycled into a new product. They form a key part of the Producer Responsibility Obligations Regulations 2007 which covers Great Britain.

Electronic waste in New Zealand is an environmental issue being addressed by community and government initiatives.

Appliance recycling is the process of dismantling scrapped home appliances to recover their parts or materials for reuse. Recycling appliances for their original or other purposes, involves disassembly, removal of hazardous components and destruction of the equipment to recover materials, generally by shredding, sorting and grading. The rate at which appliances are discarded has increased due in part to obsolescence due to technological advancement, and in part to not being designed to be repairable. The main types of appliances that are recycled are televisions, refrigerators, air conditioners, washing machines, and computers. When appliances are recycled, they can be looked upon as a valuable resources; if disposed of improperly, they can be environmentally harmful and poison ecosystems.

A take-back system or simply takeback is one of the primary channels of waste collection, especially for e-waste, besides municipal sites. Take-back is the idea that manufacturers and sellers "take back" the products that are at the end of their lives. Take-back is aimed to reduce a business' environmental impacts on the earth and also increase efficiency and lower costs for their business models. "Take-back regulations have targeted a wide array of products including packaging, batteries, automobiles, and electronics", and economic value can be found from recycling or re-manufacturing such products. "The programs benefit municipalities by lowering their overall waste disposal costs and reducing the burden on landfill sites". Although for certain companies, the take-back system is mandatory under legislation, many do it voluntarily.