In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening ("curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and may be promoted by high pressure, or mixing with a catalyst. Heat is not necessarily applied externally, but is often generated by the reaction of the resin with a curing agent. Curing results in chemical reactions that create extensive cross-linking between polymer chains to produce an infusible and insoluble polymer network.

Injection moulding is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals, glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed, and injected into a mould cavity, where it cools and hardens to the configuration of the cavity. After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mould-maker from metal, usually either steel or aluminium, and precision-machined to form the features of the desired part. Injection moulding is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars. Advances in 3D printing technology, using photopolymers that do not melt during the injection moulding of some lower-temperature thermoplastics, can be used for some simple injection moulds.

Molding or moulding is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix. This itself may have been made using a pattern or model of the final object.

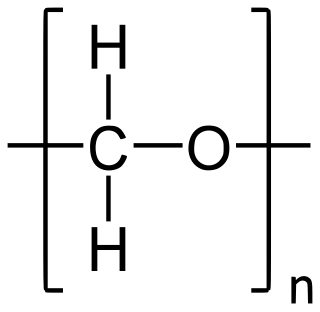

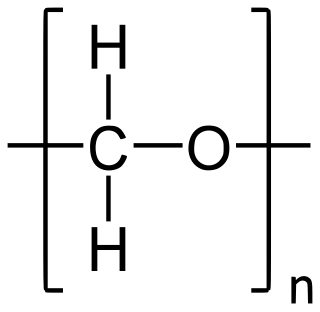

Polyoxymethylene (POM), also known as acetal, polyacetal, and polyformaldehyde, is an engineering thermoplastic used in precision parts requiring high stiffness, low friction, and excellent dimensional stability. As with many other synthetic polymers, it is produced by different chemical firms with slightly different formulas and sold variously by such names as Delrin, Kocetal, Ultraform, Celcon, Ramtal, Duracon, Kepital, Polypenco, Tenac and Hostaform.

Wood-plastic composites (WPCs) are composite materials made of wood fiber/wood flour and thermoplastic(s) such as polythene (PE), polypropylene (PP), polyvinyl chloride (PVC), or polylactic acid (PLA).

Blow molding is a manufacturing process for forming hollow plastic parts. It is also used for forming glass bottles or other hollow shapes.

Rotational molding involves a heated mold which is filled with a charge or shot weight of material. It is then slowly rotated, causing the softened material to disperse and stick to the walls of the mold forming a hollow part. In order to form an even thickness throughout the part, the mold rotates at all times during the heating phase, and then continues to rotate during the cooling phase to avoid sagging or deformation. The process was applied to plastics in the 1950s but in the early years was little used because it was a slow process restricted to a small number of plastics. Over time, improvements in process control and developments with plastic powders have resulted in increased use.

A hot runner system is an assembly of heated components used in plastic injection molds that inject molten plastic into the cavities of the mold.

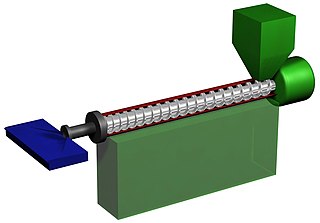

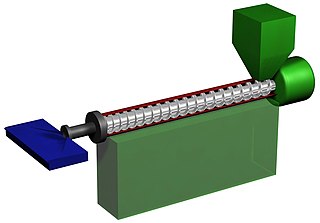

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

Masterbatch (MB) is a solid additive used for coloring or imparting other properties to plastic. Masterbatch is a concentrated mixture of pigments and/or additives which is manufactured by encapsulation during a heat process or twin screw extrusion into a carrier matrix resin, which is then cooled and further cut into a granular shape. Masterbatch allows the processor to color raw polymer economically.

The term liquid color or liquid color concentrate describes to a system consisting of a liquid binder (carrier), dyes or pigments and other additives such as process additives, stabilisers or similar. The liquid colors are mixed into the plastic for coloring or changing the properties.

Thin wall injection molding is a specialized form of conventional injection molding that focuses on mass-producing plastic parts that are thin and light so that material cost savings can be made and cycle times can be as short as possible. Shorter cycle times means higher productivity and lower costs per part.

Shut-off nozzles are used in the manufacturing process of plastic injection molding. Machine shut-off nozzles serve as the connection between the plasticizing barrel and the mold. They are mounted on the machineside of the plastic injection molding process, unlike hot runner nozzles which are mounted on the moldside of the process. Machine shut-off nozzles differ from open nozzles because of their closable melt channel.

Transfer molding is a manufacturing process in which casting material is forced into a mold. Transfer molding is different from compression molding in that the mold is enclosed rather than open to the fill plunger resulting in higher dimensional tolerances and less environmental impact. Compared to injection molding, transfer molding uses higher pressures to uniformly fill the mold cavity. This allows thicker reinforcing fiber matrices to be more completely saturated by resin. Furthermore, unlike injection molding the transfer mold casting material may start the process as a solid. This can reduce equipment costs and time dependency. The transfer process may have a slower fill rate than an equivalent injection molding process.

Plastic colorants are chemical compounds used to color plastic. Those compounds come in a form of dyes and pigments. The type of a colorant is chosen based on the type of a polymeric resin, that needs to be colored. Dyes are usually used with polycarbonates, polystyrene and acrylic polymers. Pigments are better suited for use with polyolefins.

Material extrusion-based additive manufacturing (EAM) represents one of the seven categories of 3d printing processes, defined by the ISO international standard 17296-2. While it is mostly used for plastics, under the name of FDM or FFF, it can also be used for metals and ceramics. In this AM process category, the feedstock materials are mixtures of a polymeric binder and a fine grain solid powder of metal or ceramic materials. Similar type of feedstock is also used in the Metal Injection Molding (MIM) and in the Ceramic Injection Molding (CIM) processes. The extruder pushes the material towards a heated nozzle thanks to

UBQ Materials is an Israeli cleantech company created to convert unsorted household waste into a thermoplastic composite. The company's primary product, UBQ, is a thermoplastic, sold in the form of pellets, that can be used to substitute for wood, concrete, or oil based plastics in the manufacturing of durable products. In 2018, UBQ Materials Ltd. became a Certified B Corporation.

Gas-assisted injection molding is a molding process where an inert gas is injected into the melted plastic pushing it further into the mold and resulting in hollow parts.

Micro injection molding is a molding process for the manufacture of plastics components for shot weights of 1 to 0.1 grams with tolerances in the range of 10 to 100 microns. This molding process permits the manufacture of complicated small geometries with maximum possible accuracy and precision.

Cube mold technology is a molding process for the manufacture of plastics components. This molding process allows to manufacture circular parts. This technology was introduced by Foboha and Arburg.