Analytical chemistry studies and uses instruments and methods to separate, identify, and quantify matter. In practice, separation, identification or quantification may constitute the entire analysis or be combined with another method. Separation isolates analytes. Qualitative analysis identifies analytes, while quantitative analysis determines the numerical amount or concentration.

In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. Such a standard could be another measurement device of known accuracy, a device generating the quantity to be measured such as a voltage, a sound tone, or a physical artifact, such as a meter ruler.

Metrology is the scientific study of measurement. It establishes a common understanding of units, crucial in linking human activities. Modern metrology has its roots in the French Revolution's political motivation to standardise units in France when a length standard taken from a natural source was proposed. This led to the creation of the decimal-based metric system in 1795, establishing a set of standards for other types of measurements. Several other countries adopted the metric system between 1795 and 1875; to ensure conformity between the countries, the Bureau International des Poids et Mesures (BIPM) was established by the Metre Convention. This has evolved into the International System of Units (SI) as a result of a resolution at the 11th General Conference on Weights and Measures (CGPM) in 1960.

The ISO 9000 family is a set of five quality management systems (QMS) standards by the International Organization for Standardization (ISO) that help organizations ensure they meet customer and other stakeholder needs within statutory and regulatory requirements related to a product or service. ISO 9000 deals with the fundamentals of QMS, including the seven quality management principles that underlie the family of standards. ISO 9001 deals with the requirements that organizations wishing to meet the standard must fulfill. ISO 9002 is a model for quality assurance in production and installation. ISO 9003 for quality assurance in final inspection and test. ISO 9004 gives guidance on achieving sustained organizational success.

Traceability is the capability to trace something. In some cases, it is interpreted as the ability to verify the history, location, or application of an item by means of documented recorded identification.

Quality assurance (QA) is the term used in both manufacturing and service industries to describe the systematic efforts taken to assure that the product(s) delivered to customer(s) meet with the contractual and other agreed upon performance, design, reliability, and maintainability expectations of that customer. The core purpose of Quality Assurance is to prevent mistakes and defects in the development and production of both manufactured products, such as automobiles and shoes, and delivered services, such as automotive repair and athletic shoe design. Assuring quality and therefore avoiding problems and delays when delivering products or services to customers is what ISO 9000 defines as that "part of quality management focused on providing confidence that quality requirements will be fulfilled". This defect prevention aspect of quality assurance differs from the defect detection aspect of quality control and has been referred to as a shift left since it focuses on quality efforts earlier in product development and production and on avoiding defects in the first place rather than correcting them after the fact.

Chemometrics is the science of extracting information from chemical systems by data-driven means. Chemometrics is inherently interdisciplinary, using methods frequently employed in core data-analytic disciplines such as multivariate statistics, applied mathematics, and computer science, in order to address problems in chemistry, biochemistry, medicine, biology and chemical engineering. In this way, it mirrors other interdisciplinary fields, such as psychometrics and econometrics.

The limit of detection is the lowest signal, or the lowest corresponding quantity to be determined from the signal, that can be observed with a sufficient degree of confidence or statistical significance. However, the exact threshold used to decide when a signal significantly emerges above the continuously fluctuating background noise remains arbitrary and is a matter of policy and often of debate among scientists, statisticians and regulators depending on the stakes in different fields.

Accreditation is the independent, third-party evaluation of a conformity assessment body against recognised standards, conveying formal demonstration of its impartiality and competence to carry out specific conformity assessment tasks.

In metrology, measurement uncertainty is the expression of the statistical dispersion of the values attributed to a measured quantity. All measurements are subject to uncertainty and a measurement result is complete only when it is accompanied by a statement of the associated uncertainty, such as the standard deviation. By international agreement, this uncertainty has a probabilistic basis and reflects incomplete knowledge of the quantity value. It is a non-negative parameter.

ISO/IEC 17025General requirements for the competence of testing and calibration laboratories is the main standard used by testing and calibration laboratories. In most countries, ISO/IEC 17025 is the standard for which most labs must hold accreditation in order to be deemed technically competent. In many cases, suppliers and regulatory authorities will not accept test or calibration results from a lab that is not accredited. Originally known as ISO/IEC Guide 25, ISO/IEC 17025 was initially issued by ISO/IEC in 1999. There are many commonalities with the ISO 9000 standard, but ISO/IEC 17025 is more specific in requirements for competence and applies directly to those organizations that produce testing and calibration results and is based on more technical principles. Laboratories use ISO/IEC 17025 to implement a quality system aimed at improving their ability to consistently produce valid results. Material in the standard also forms the basis for accreditation from an accreditation body.

Similarly, the activity of qualifying systems and equipment is divided into a number of subsections including the following:

ISO 15189 Medical laboratories — Requirements for quality and competence is an international standard that specifies the quality management system requirements particular to medical laboratories. The standard was developed by the International Organisation for Standardization's Technical Committee 212. ISO/TC 212 assigned ISO 15189 to a working group to prepare the standard based on the details of ISO/IEC 17025:1999 General requirements for the competence of testing and calibration laboratories. This working group included provision of advice to medical laboratory users, including specifics on the collection of patient samples, the interpretation of test results, acceptable turnaround times, how testing is to be provided in a medical emergency, and the lab's role in the education and training of health care staff. While the standard is based on ISO/IEC 17025 and ISO 9001, it is a unique document that takes into consideration the specific requirements of the medical environment and the importance of the medical laboratory to patient care.

Certified reference materials (CRMs) are 'controls' or standards used to check the quality and metrological traceability of products, to validate analytical measurement methods, or for the calibration of instruments. A certified reference material is a particular form of measurement standard.

A test method is a method for a test in science or engineering, such as a physical test, chemical test, or statistical test. It is a definitive procedure that produces a test result. In order to ensure accurate and relevant test results, a test method should be "explicit, unambiguous, and experimentally feasible.", as well as effective and reproducible.

The South African National Accreditation System (SANAS) is the official accreditation body for South Africa. Founded in 1996, SANAS is headquartered in Pretoria, South Africa. SANAS accreditation certificates are a formal recognition by the Government of South Africa that an organisation is competent to perform specific tasks.

Verification and validation are independent procedures that are used together for checking that a product, service, or system meets requirements and specifications and that it fulfills its intended purpose. These are critical components of a quality management system such as ISO 9000. The words "verification" and "validation" are sometimes preceded with "independent", indicating that the verification and validation is to be performed by a disinterested third party. "Integration verification and validation" can be abbreviated as "IV&V".

ISO 10012:2003, Measurement management systems - Requirements for measurement processes and measuring equipment is the ISO standard that specifies generic requirements and provides guidance for the management of measurement processes and metrological confirmation of measuring equipment used to support and demonstrate compliance with metrological requirements. It specifies quality management requirements of a measurement management system that can be used by an organization performing measurements as part of the overall management system, and to ensure metrological requirements are met.

Analytical quality control, commonly shortened to AQC, refers to all those processes and procedures designed to ensure that the results of laboratory analysis are consistent, comparable, accurate and within specified limits of precision. Constituents submitted to the analytical laboratory must be accurately described to avoid faulty interpretations, approximations, or incorrect results. The qualitative and quantitative data generated from the laboratory can then be used for decision making. In the chemical sense, quantitative analysis refers to the measurement of the amount or concentration of an element or chemical compound in a matrix that differs from the element or compound. Fields such as industry, medicine, and law enforcement can make use of AQC.

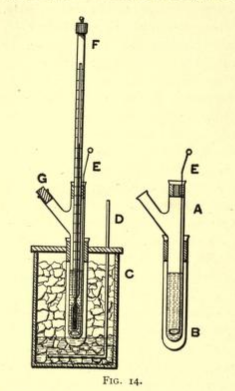

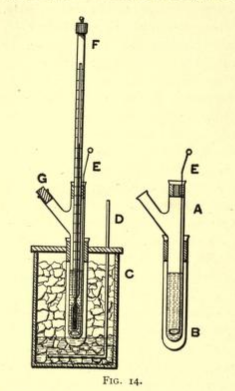

The freezing point depression osmometer is an osmometer that is used in determining a solution's osmotic concentration as its osmotically active aspects depress its freezing point.