This article needs additional citations for verification .(December 2009) (Learn how and when to remove this template message) |

Radial stress is stress towards or away from the central axis of a component.

This article needs additional citations for verification .(December 2009) (Learn how and when to remove this template message) |

Radial stress is stress towards or away from the central axis of a component.

The walls of pressure vessels generally undergo triaxial loading. For cylindrical pressure vessels, the normal loads on a wall element are:

The radial stress for a thick-walled cylinder is equal and opposite to the gauge pressure on the inside surface, and zero on the outside surface. The circumferential stress and longitudinal stresses are usually much larger for pressure vessels, and so for thin-walled instances, radial stress is usually neglected.

The radial stress for a thick walled pipe at a point from the central axis is given by

where is the inner radius, is the outer radius, is the inner absolute pressure and is the outer absolute pressure. [1] Maximum radial stress occurs when (at the inside surface) and is equal to gauge pressure, or . [2]

Isaac Newton's rotating bucket argument was designed to demonstrate that true rotational motion cannot be defined as the relative rotation of the body with respect to the immediately surrounding bodies. It is one of five arguments from the "properties, causes, and effects" of "true motion and rest" that support his contention that, in general, true motion and rest cannot be defined as special instances of motion or rest relative to other bodies, but instead can be defined only by reference to absolute space. Alternatively, these experiments provide an operational definition of what is meant by "absolute rotation", and do not pretend to address the question of "rotation relative to what?" General relativity dispenses with absolute space and with physics whose cause is external to the system, with the concept of geodesics of spacetime.

Pressure is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure is the pressure relative to the ambient pressure.

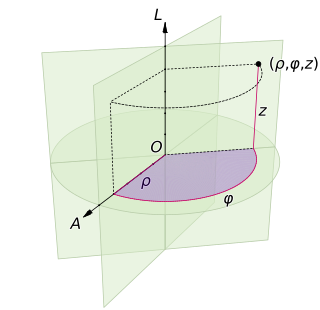

A cylindrical coordinate system is a three-dimensional coordinate system that specifies point positions by the distance from a chosen reference axis, the direction from the axis relative to a chosen reference direction, and the distance from a chosen reference plane perpendicular to the axis. The latter distance is given as a positive or negative number depending on which side of the reference plane faces the point.

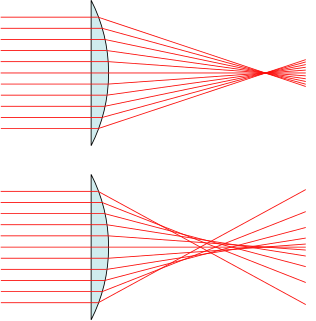

Spherical aberration (SA) is a type of aberration found in optical systems that use elements with spherical surfaces. Lenses and curved mirrors are most often made with surfaces that are spherical, because this shape is easier to form than non-spherical curved surfaces. Light rays that strike a spherical surface off-centre are refracted or reflected more or less than those that strike close to the centre. This deviation reduces the quality of images produced by optical systems.

Hemodynamics or haemodynamics are the dynamics of blood flow. The circulatory system is controlled by homeostatic mechanisms of autoregulation, just as hydraulic circuits are controlled by control systems. The haemodynamic response continuously monitors and adjusts to conditions in the body and its environment. Thus, haemodynamics explains the physical laws that govern the flow of blood in the blood vessels.

In mathematics, engineering, and manufacturing, a solid of revolution is a solid figure obtained by rotating a plane curve around some straight line that lies on the same plane.

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.

Vascular resistance is the resistance that must be overcome to push blood through the circulatory system and create flow.The resistance offered by the systemic circulation is known as the systemic vascular resistance (SVR) or may sometimes be called by the older term total peripheral resistance (TPR), while the resistance offered by the pulmonary circulation is known as the pulmonary vascular resistance (PVR). Systemic vascular resistance is used in calculations of blood pressure, blood flow, and cardiac function. Vasoconstriction increases SVR, whereas vasodilation decreases SVR.

In structural engineering, buckling is the sudden change in shape (deformation) of a structural component under load, such as the bowing of a column under compression or the wrinkling of a plate under shear. If a structure is subjected to a gradually increasing load, when the load reaches a critical level, a member may suddenly change shape and the structure and component is said to have buckled. Euler's critical load and Johnson's parabolic formula are used to determine the buckling stress in slender columns.

In mechanics, a cylinder stress is a stress distribution with rotational symmetry; that is, which remains unchanged if the stressed object is rotated about some fixed axis.

In classical geometry, a radius of a circle or sphere is any of the line segments from its center to its perimeter, and in more modern usage, it is also their length. The name comes from the Latin radius, meaning ray but also the spoke of a chariot wheel. The plural of radius can be either radii or the conventional English plural radiuses. The typical abbreviation and mathematical variable name for radius is r. By extension, the diameter d is defined as twice the radius:

A spherometer is an instrument for the precise measurement of the radius of curvature of a sphere or a curved surface. Originally, these instruments were primarily used by opticians to measure the curvature of the surface of a lens.

In the field of solid mechanics, torsion is the twisting of an object due to an applied torque. Torsion is expressed in either the Pascal (Pa), an SI unit for newtons per square metre, or in pounds per square inch (psi) while torque is expressed in newton metres (N·m) or foot-pound force (ft·lbf). In sections perpendicular to the torque axis, the resultant shear stress in this section is perpendicular to the radius.

Roundness is the measure of how closely the shape of an object approaches that of a mathematically perfect circle. Roundness applies in two dimensions, such as the cross sectional circles along a cylindrical object such as a shaft or a cylindrical roller for a bearing. In geometric dimensioning and tolerancing, control of a cylinder can also include its fidelity to the longitudinal axis, yielding cylindricity. The analogue of roundness in three dimensions is sphericity.

A head is one of the end caps on a cylindrically shaped pressure vessel.

Toroidal inductors and transformers are inductors and transformers which use magnetic cores with a toroidal shape. They are passive electronic components, consisting of a circular ring or donut shaped magnetic core of ferromagnetic material such as laminated iron, iron powder, or ferrite, around which wire is wound.

In the design of fluid bearings, the Sommerfeld number (S) is a dimensionless quantity used extensively in hydrodynamic lubrication analysis. The Sommerfeld number is very important in lubrication analysis because it contains all the variables normally specified by the designer.

Rotary piercing is a hot working metalworking process for forming thick-walled seamless tubing. There are two types: the Mannesmann process and the Stiefel process.

Bearing pressure is a particular case of contact mechanics often occurring in cases where a convex surface contacts a concave surface. Excessive contact pressure can lead to a typical bearing failure such as a plastic deformation similar to peening. This problem is also referred to as bearing resistance.