Atomic absorption spectroscopy (AAS) and atomic emission spectroscopy (AES) is a spectroanalytical procedure for the quantitative determination of chemical elements by free atoms in the gaseous state. Atomic absorption spectroscopy is based on absorption of light by free metallic ions.

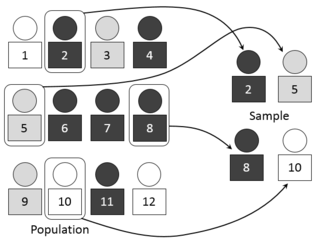

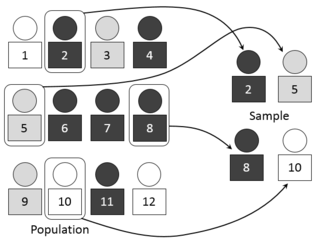

In statistics, quality assurance, and survey methodology, sampling is the selection of a subset or a statistical sample of individuals from within a statistical population to estimate characteristics of the whole population. The subset is meant to reflect the whole population and statisticians attempt to collect samples that are representative of the population. Sampling has lower costs and faster data collection compared to recording data from the entire population, and thus, it can provide insights in cases where it is infeasible to measure an entire population.

A mixture is a material made up of two or more different chemical substances which can be separated by physical method. A mixture is the physical combination of two or more substances in which the identities are retained and are mixed in the form of solutions, suspensions and colloids.

A splitting maul also known as a block buster, block splitter, chop and maul, sledge axe, go-devil or hamaxe is a heavy, long-handled axe used for splitting a piece of wood along its grain. One side of its head is like a sledgehammer, and the other side is like an axe.

A microprobe is an instrument that applies a stable and well-focused beam of charged particles to a sample.

An analytical balance is a class of balance designed to measure small mass in the sub-milligram range. The measuring pan of an analytical balance is inside a transparent enclosure with doors so that dust does not collect and so any air currents in the room do not affect the balance's operation. This enclosure is often called a draft shield. The use of a mechanically vented balance safety enclosure, which has uniquely designed acrylic airfoils, allows a smooth turbulence-free airflow that prevents balance fluctuation and the measure of mass down to 1 μg without fluctuations or loss of product. Also, the sample must be at room temperature to prevent natural convection from forming air currents inside the enclosure from causing an error in reading. Single pan mechanical substitution balance is a method of maintaining consistent response throughout the useful capacity of the balance. This is achieved by maintaining a constant load on the balance beam and thus the fulcrum, by subtracting mass on the same side of the beam as which the sample is added.

An electrostatic precipitator (ESP) is a filterless device that removes fine particles, such as dust and smoke, from a flowing gas using the force of an induced electrostatic charge minimally impeding the flow of gases through the unit.

A wedge is a triangular shaped tool, a portable inclined plane, and one of the six simple machines. It can be used to separate two objects or portions of an object, lift up an object, or hold an object in place. It functions by converting a force applied to its blunt end into forces perpendicular (normal) to its inclined surfaces. The mechanical advantage of a wedge is given by the ratio of the length of its slope to its width. Although a short wedge with a wide angle may do a job faster, it requires more force than a long wedge with a narrow angle.

A Coulter counter is an apparatus for counting and sizing particles suspended in electrolytes. The Coulter counter is the commercial term for the technique known as resistive pulse sensing or electrical zone sensing. The apparatus is based on the Coulter principle named after its inventor, Wallace H. Coulter.

A dust collector is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas. Designed to handle high-volume dust loads, a dust collector system consists of a blower, dust filter, a filter-cleaning system, and a dust receptacle or dust removal system. It is distinguished from air purifiers, which use disposable filters to remove dust.

A coal preparation plant is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or ships.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

In granulometry, the particle-size distribution (PSD) of a powder, or granular material, or particles dispersed in fluid, is a list of values or a mathematical function that defines the relative amount, typically by mass, of particles present according to size. Significant energy is usually required to disintegrate soil, etc. particles into the PSD that is then called a grain size distribution.

In analytical chemistry, sub-sampling is a procedure by which a small, representative sample is taken from a larger sample. Good sub-sampling technique becomes important when the large sample is not homogeneous.

Gy's sampling theory is a theory about the sampling of materials, developed by Pierre Gy from the 1950s to beginning 2000s in articles and books including:

During sampling of granular materials, correct sampling is defined in Gy's sampling theory as a sampling scenario in which all particles in a population have the same probability of ending up in the sample.

Nanofluidic circuitry is a nanotechnology aiming for control of fluids in nanometer scale. Due to the effect of an electrical double layer within the fluid channel, the behavior of nanofluid is observed to be significantly different compared with its microfluidic counterparts. Its typical characteristic dimensions fall within the range of 1–100 nm. At least one dimension of the structure is in nanoscopic scale. Phenomena of fluids in nano-scale structure are discovered to be of different properties in electrochemistry and fluid dynamics.

The clean air delivery rate (CADR) is a figure of merit that is the cubic feet per minute (CFM) of air that has had all the particles of a given size distribution removed. For air filters that have air flowing through them, it is the fraction of particles that have been removed from the air, multiplied by the air flow rate through the device. More precisely, it is the CFM of air in a 1,008-cubic-foot (28.5 m3) room that has had all the particles of a given size distribution removed from the air, over and above the rate at which the particles are naturally falling out of the air. Different filters have different abilities to remove different particle distributions, so three CADR's for a given device are typically measured: smoke, pollen, and dust. By combining the amount of airflow and particle removal efficiency, consumers are less likely to be misled by a high efficiency filter that is filtering a small amount of air, or by a high volume of air that is not being filtered very well.

Sensor-based sorting, is an umbrella term for all applications in which particles are detected using a sensor technique and rejected by an amplified mechanical, hydraulic or pneumatic process.

Workplace exposure monitoring is the monitoring of substances in a workplace that are chemical or biological hazards. It is performed in the context of workplace exposure assessment and risk assessment. Exposure monitoring analyzes hazardous substances in the air or on surfaces of a workplace, and is complementary to biomonitoring, which instead analyzes toxicants or their effects within workers.