A scuba set, originally just scuba, is any breathing apparatus that is entirely carried by an underwater diver and provides the diver with breathing gas at the ambient pressure. Scuba is an anacronym for self-contained underwater breathing apparatus. Although strictly speaking the scuba set is only the diving equipment that is required for providing breathing gas to the diver, general usage includes the harness or rigging by which it is carried, and those accessories which are integral parts of the harness and breathing apparatus assembly, such as a jacket or wing style buoyancy compensator and instruments mounted in a combined housing with the pressure gauge, and in the looser sense, it has been used to refer to all the diving equipment used by the scuba diver, though this would more commonly and accurately be termed scuba equipment or scuba gear. Scuba is overwhelmingly the most common underwater breathing system used by recreational divers and is also used in professional diving when it provides advantages, usually of mobility and range, over surface-supplied diving systems, and is allowed by the relevant legislation and code of practice.

A self-contained breathing apparatus (SCBA) is a device worn to provide an autonomous supply of breathable gas in an atmosphere that is immediately dangerous to life or health. They are typically used in firefighting and industry. The term self-contained means that the SCBA is not dependent on a remote supply of breathing gas. If designed for use under water, it is also known as a scuba set. When not used underwater, they are sometimes called industrial breathing sets. Some types are also referred to as a compressed air breathing apparatus (CABA) or simply breathing apparatus (BA). Unofficial names include air pack, air tank, oxygen cylinder or simply pack, which are mostly used in firefighting.

Liquefied petroleum gas is a fuel gas which contains a flammable mixture of hydrocarbon gases, specifically propane, propylene, butylene, isobutane, and n-butane.

A diving cylinder or diving gas cylinder is a gas cylinder used to store and transport high pressure gas used in diving operations. This may be breathing gas used with a scuba set, in which case the cylinder may also be referred to as a scuba cylinder, scuba tank or diving tank. When used for an emergency gas supply for surface supplied diving or scuba, it may be referred to as a bailout cylinder or bailout bottle. It may also be used for surface-supplied diving or as decompression gas. A diving cylinder may also be used to supply inflation gas for a dry suit or buoyancy compensator. Cylinders provide gas to the diver through the demand valve of a diving regulator or the breathing loop of a diving rebreather.

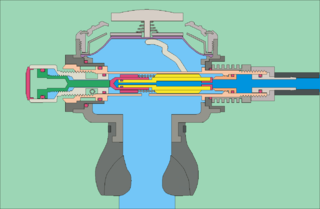

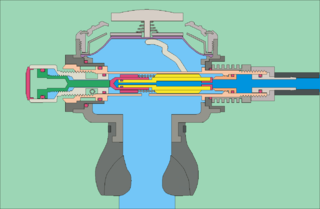

A diving regulator is a pressure regulator that controls the pressure of breathing gas for diving. The most commonly recognised application is to reduce pressurized breathing gas to ambient pressure and deliver it to the diver, but there are also other types of gas pressure regulator used for diving applications. The gas may be air or one of a variety of specially blended breathing gases. The gas may be supplied from a scuba cylinder carried by the diver, in which case it is called a scuba regulator, or via a hose from a compressor or high-pressure storage cylinders at the surface in surface-supplied diving. A gas pressure regulator has one or more valves in series which reduce pressure from the source, and use the downstream pressure as feedback to control the delivered pressure, or the upstream pressure as feedback to prevent excessive flow rates, lowering the pressure at each stage.

A diving air compressor is a gas compressor that can provide breathing air directly to a surface-supplied diver, or fill diving cylinders with high-pressure air pure enough to be used as a breathing gas. A low pressure diving air compressor usually has a delivery pressure of up to 30 bar, which is regulated to suit the depth of the dive. A high pressure diving compressor has a delivery pressure which is usually over 150 bar, and is commonly between 200 and 300 bar. The pressure is limited by an overpressure valve which may be adjustable.

A gas cylinder is a pressure vessel for storage and containment of gases at above atmospheric pressure. High-pressure gas cylinders are also called bottles. Inside the cylinder the stored contents may be in a state of compressed gas, vapor over liquid, supercritical fluid, or dissolved in a substrate material, depending on the physical characteristics of the contents. A typical gas cylinder design is elongated, standing upright on a flattened bottom end, with the valve and fitting at the top for connecting to the receiving apparatus.

Autogas or LPG is liquefied petroleum gas (LPG) used as a fuel in internal combustion engines in vehicles as well as in stationary applications such as generators. It is a mixture of propane and butane.

Industrial gases are the gaseous materials that are manufactured for use in industry. The principal gases provided are nitrogen, oxygen, carbon dioxide, argon, hydrogen, helium and acetylene, although many other gases and mixtures are also available in gas cylinders. The industry producing these gases is also known as industrial gas, which is seen as also encompassing the supply of equipment and technology to produce and use the gases. Their production is a part of the wider chemical Industry.

Worthington Industries, Inc. is a global diversified metals manufacturing company based in Columbus, Ohio. It is a steel processor and manufacturer of pressure vessels, such as propane, oxygen and helium tanks, hand torches, refrigerant and industrial cylinders, camping cylinders, exploration, recovery and production products for global energy markets; water system tanks for storage, treatment, heating, expansion and flow control, and compressed natural gas storage cylinders. The company also manufactures framing systems for mid-rise buildings and steel pallets and racks for shipping. It is the largest independent processor of flat-rolled steel in the United States. The company takes steel from steel producers and processes it for customers in industries including automotive, lawn and garden, construction, hardware, office furniture, electrical control, leisure and recreation, appliance, agriculture and HVAC.

A scuba manifold is a device incorporating one or more valves and one or more gas outlets with scuba regulator connections, used to connect two or more diving cylinders containing breathing gas, providing a greater amount of gas for longer dive times or deeper dives. An isolation manifold allows the connection between the cylinders to be closed in the case of a leak from one of the cylinders or its valve or regulator, conserving the gas in the other cylinder. Diving with two or more cylinders is often associated with technical diving. Almost all manifold assemblies include one cylinder valve for each cylinder, and the overwhelming majority are for two cylinders.

A pressure regulator is a valve that controls the pressure of a fluid to a desired value, using negative feedback from the controlled pressure. Regulators are used for gases and liquids, and can be an integral device with a pressure setting, a restrictor and a sensor all in the one body, or consist of a separate pressure sensor, controller and flow valve.

Oxy-fuel welding and oxy-fuel cutting are processes that use fuel gases and oxygen to weld or cut metals. French engineers Edmond Fouché and Charles Picard became the first to develop oxygen-acetylene welding in 1903. Pure oxygen, instead of air, is used to increase the flame temperature to allow localised melting of the workpiece material in a room environment. A common propane/air flame burns at about 2,250 K, a propane/oxygen flame burns at about 2,526 K, an oxyhydrogen flame burns at 3,073 K and an acetylene/oxygen flame burns at about 3,773 K.

Orbital welding is a specialized area of welding whereby the arc is rotated mechanically through 360° around a static workpiece, an object such as a pipe, in a continuous process. The process was developed to address the issue of operator error in gas tungsten arc welding processes (GTAW), to support uniform welding around a pipe that would be significantly more difficult using a manual welding process, and to ensure high quality repeatable welds that would meet more stringent weld criteria set by ASME. In orbital welding, computer-controlled process runs with little intervention from the operator.

Nitrogen generators and stations are stationary or mobile air-to-nitrogen production complexes.

A cryogenic gas plant is an industrial facility that creates molecular oxygen, molecular nitrogen, argon, krypton, helium, and xenon at relatively high purity. As air is made up of nitrogen, the most common gas in the atmosphere, at 78%, with oxygen at 19%, and argon at 1%, with trace gasses making up the rest, cryogenic gas plants separate air inside a distillation column at cryogenic temperatures to produce high purity gasses such as argon, nitrogen, oxygen, and many more with 1 ppm or less impurities. The process is based on the general theory of the Hampson-Linde cycle of air separation, which was invented by Carl von Linde in 1895.

A gas cabinet is a metallic enclosure which is used to provide local exhaust ventilation system for virtually all of the gases used or generated in the semiconductor, solar, MEMS, NANO, solar PV, manufacturing and other advanced technologies.

Several types of valve connections for propane, butane, and LPG containers exist for transport and storage, sometimes with overlapping usage and applications, and there are major differences in usage between different countries. Even within a single country more than one type can be in use for a specific application. This requires adequate tooling and adapters for replenishment in multiple countries. For example for overlanders and users of autogas traveling with a container originating in one country to other parts of the world this is a major concern. This article describes existing standards and the standards in use for a number of countries. For disposable containers the availability per country is described. Filling stations may be able and allowed to fill foreign containers if adequate adapters are available. Adapters are provided by, amongst others, camping stores. The iOverlander database maintained by travelers, My LPG and the Facebook group "Cooking Gas Around the World" provide more information about individual sources per country. Much general information about global LPG use and standardization is available from the World LPG Association and the AEGPL

A scuba cylinder valve or pillar valve is a high pressure manually operated screw-down shut off valve fitted to the neck of a scuba cylinder to control breathing gas flow to and from the pressure vessel and to provide a connection with the scuba regulator or filling whip. Cylinder valves are usually machined from brass and finished with a protective and decorative layer of chrome plating. A metal or plastic dip tube or valve snorkel screwed into the bottom of the valve extends into the cylinder to reduce the risk of liquid or particulate contaminants in the cylinder getting into the gas passages when the cylinder is inverted, and blocking or jamming the regulator.

The mechanism of diving regulators is the arrangement of components and function of gas pressure regulators used in the systems which supply breathing gases for underwater diving. Both free-flow and demand regulators use mechanical feedback of the downstream pressure to control the opening of a valve which controls gas flow from the upstream, high-pressure side, to the downstream, low-pressure side of each stage. Flow capacity must be sufficient to allow the downstream pressure to be maintained at maximum demand, and sensitivity must be appropriate to deliver maximum required flow rate with a small variation in downstream pressure, and for a large variation in supply pressure, without instability of flow. Open circuit scuba regulators must also deliver against a variable ambient pressure. They must be robust and reliable, as they are life-support equipment which must function in the relatively hostile seawater environment, and the human interface must be comfortable over periods of several hours.