Computer-aided design (CAD) is the use of computers to aid in the creation, modification, analysis, or optimization of a design. CAD software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The term CADD is also used.

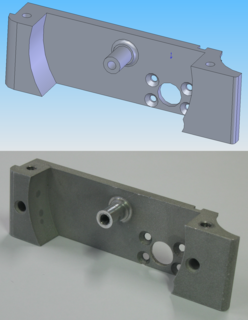

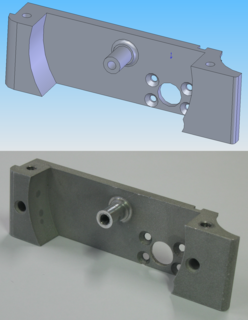

Computer-aided manufacturing (CAM) also known as Computer-aided Modeling or Computer-aided Machining is the use of software to control machine tools and related ones in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common; CAM may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material, while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the machine tool. CAM is used in many schools alongside Computer-Aided Design (CAD) to create objects.

Mastercam is a suite of Computer-Aided Manufacturing (CAM) and CAD/CAM software applications. Founded in MA in 1983, CNC Software, Inc. is one of the oldest developers of PC-based computer-aided design / computer-aided manufacturing (CAD/CAM) software. They are one of the first to introduce CAD/CAM software designed for both machinists and engineers. Mastercam, CNC Software’s main product, started as a 2D CAM system with CAD tools that let machinists design virtual parts on a computer screen and also guided computer numerical controlled (CNC) machine tools in the manufacture of parts. Since then, Mastercam has grown into the most widely used CAD/CAM package in the world. CNC Software, Inc. is now located in Tolland, Connecticut.

A machinist is a tradesperson who machines using hand tools and machine tools to create or modify a part that is made of metal, plastics, or wood, although plastics or wood machining is rarely manufactured by machinists as those materials require lesser skill and almost all the work performed by a machinist is done on metal. A machinist is to metal what a carpenter or cabinet maker is to wood.

Numerical control is the automated control of machining tools and 3D printers by means of a computer. A CNC machine processes a piece of material to meet specifications by following a coded programmed instruction and without a manual operator.

G-code, which has many variants, is the common name for the most widely used computer numerical control (CNC) programming language. It is used mainly in computer-aided manufacturing to control automated machine tools.

Diamond turning is turning using a cutting tool with a diamond tip. It is a process of mechanical machining of precision elements using lathes or derivative machine tools equipped with natural or synthetic diamond-tipped tool bits. The term single-point diamond turning (SPDT) is sometimes applied, although as with other lathe work, the "single-point" label is sometimes only nominal. The process of diamond turning is widely used to manufacture high-quality aspheric optical elements from crystals, metals, acrylic, and other materials. Plastic optics are frequently molded using diamond turned mold inserts. Optical elements produced by the means of diamond turning are used in optical assemblies in telescopes, video projectors, missile guidance systems, lasers, scientific research instruments, and numerous other systems and devices. Most SPDT today is done with computer numerical control (CNC) machine tools. Diamonds also serve in other machining processes, such as milling, grinding, and honing. Diamond turned surfaces have a high specular brightness and require no additional polishing or buffing, unlike other conventionally machined surfaces.

Tebis is a CAD/CAM program supplied by Tebis Technische Informationssysteme AG headquartered in Martinsried near Munich/Germany.

A tool and cutter grinder is used to sharpen milling cutters and tool bits along with a host of other cutting tools.

A metal lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of applications, and a broad range of materials. In machining jargon, where the larger context is already understood, they are usually simply called lathes, or else referred to by more-specific subtype names. These rigid machine tools remove material from a rotating workpiece via the movements of various cutting tools, such as tool bits and drill bits.

Claris CAD was a two-dimensional computer-aided design program for Apple Inc. Macintosh.

BricsCAD is a software application for computer-aided design (CAD), developed by Bricsys nv. The company was founded in 2002 by Erik de Keyser, a longtime CAD entrepreneur. In 2011 Bricsys acquired the intellectual property rights from Ledas for constraints-based parametric design tools, permitting the development of applications in the areas of direct modeling and assembly design. Bricsys' headquartered are in Ghent, Belgium, has additional development centers in Nizhny Novgorod and Novosibirsk, Russia; Bucharest, Romania and Singapore. Bricsys is a founding member of the Open Design Alliance, and joined the BuildingSMART International consortium in December 2016.

BobCAD-CAM is a developer of CAD/CAM software for the CNC metalworking and manufacturing industry. Based in Clearwater, FL, BobCAD-CAM has a staff of approximately 85 employees. Since opening in 1985 they've developed a reputation in the industry as having one of the most powerful and affordable CAD-CAM software available.

A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, such as wood, composites, aluminium, steel, plastics, glass, and foams. CNC routers can perform the tasks of many carpentry shop machines such as the panel saw, the spindle moulder, and the boring machine. They can also cut joinery such as mortises and tenons.

WorkNC is a Computer aided manufacturing (CAM) software developed by Sescoi for multi-axis machining.

MEDUSA, is a CAD program used in the areas of mechanical and plant engineering by manufacturers and Engineering, Procurement and Construction (EPC) companies. The system's history is closely tied to the beginnings of mainstream CAD and the research culture fostered by Cambridge University and the UK government as well as the resulting transformation of Cambridge into a world-class tech centre in the 1980s.

SprutCAM is a mid-level CAM program that runs on Microsoft Windows and was developed by SPRUT Technology, LTD. SprutCAM provide off-line CNC programming for cutting, wire EDM, 2, 3 and multi axial machining with support Multi-tasking Turn-Milling centers with live tooling and robots (OLP).

TranslateCAD is a tool for computer-aided translation software designed to extract translatable text from CAD drawings saved in the industry-standard DXF format - regardless of the CAD software used to create such drawings - so that professional translators are able to translate in plain text using a number of CAT tools available.

A Post Processor is a unique "driver" specific to a CNC machine, robot or mechanism; some machines start at different locations or require extra movement between each operation, the Post-Processor works with the CAM software or off-line programming software to make sure the G-Code output or program is correct for a specific Trademark machine Control Cabinet CAM software uses geometry from a CAD model and converts it to G-code. The CAM software analyzes the CAD model, determines what tooling and toolpaths will be used to mill the desired features. Doing so requires a CAM post processor that generates the exact G-code dialect used by the machine Control Module that is being targeted. An instance of such a translation is often referred to as a "post". There will be a different “post” for each G-code dialect the CAM software supports. Post Processors, rather the “post” uses an intermediate format that captures the G-code commands in a dialect-independent form. Most CAM software accomplishes this with an intermediate format called "CL.Data."

ABViewer is multifunctional software for working with AutoCAD DWG, DXF, PLT, STEP, IGES, STL and other 2D and 3D CAD files. The application allows creating and editing drawings as well as saving them to AutoCAD DWG/DXF, PDF, JPG and a number of other vector and raster file formats.