A water turbine is a rotary machine that converts kinetic energy and potential energy of water into mechanical work.

A windmill is a structure that converts wind power into rotational energy using vanes called sails or blades, by tradition specifically to mill grain (gristmills), but in some parts of the English-speaking world, the term has also been extended to encompass windpumps, wind turbines, and other applications. The term wind engine is also sometimes used to describe such devices.

George Westinghouse Jr. was an American entrepreneur and engineer based in Pittsburgh, Pennsylvania who created the railway air brake and was a pioneer of the electrical industry, receiving his first patent at the age of 19. Westinghouse saw the potential of using alternating current for electric power distribution in the early 1880s and put all his resources into developing and marketing it. This put Westinghouse's business in direct competition with Thomas Edison, who marketed direct current for electric power distribution. In 1911 Westinghouse received the American Institute of Electrical Engineers's (AIEE) Edison Medal "For meritorious achievement in connection with the development of the alternating current system". He founded the Westinghouse Electric Corporation in 1886.

A windpump is a wind-driven device which is used for pumping water.

A power station, also referred to as a power plant and sometimes generating station or generating plant, is an industrial facility for the generation of electric power. Power stations are generally connected to an electrical grid.

The Korea General Machinery Trading Corporation (Korean: 조선기계무역총회사) is a North Korean machine company. It is headquartered in the Tongdaewon District near the capital, Pyongyang.

Turbomachinery, in mechanical engineering, describes machines that transfer energy between a rotor and a fluid, including both turbines and compressors. While a turbine transfers energy from a fluid to a rotor, a compressor transfers energy from a rotor to a fluid. It is an important application of fluid mechanics.

The Voith Group is a German manufacturer of machines for the pulp and paper industry, technical equipment for hydropower plants and drive and braking systems. Founded in 1867, the company today has around 22,479 employees, sales of €5.5 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

Airborne wind energy (AWE) is the direct use or generation of wind energy by the use of aerodynamic or aerostatic lift devices. AWE technology is able to harvest high altitude winds, in contrast to wind turbines, which use a rotor mounted on a tower.

Wind power has been used as long as humans have put sails into the wind. Wind-powered machines used to grind grain and pump water — the windmill and wind pump — were developed in what is now Iran, Afghanistan, and Pakistan by the 9th century. Wind power was widely available and not confined to the banks of fast-flowing streams, or later, requiring sources of fuel. Wind-powered pumps drained the polders of the Netherlands, and in arid regions such as the American midwest or the Australian outback, wind pumps provided water for livestock and steam engines.

The following outline is provided as an overview of and topical guide to machines:

A black start is the process of restoring an electric power station, a part of an electric grid or an industrial plant, to operation without relying on the external electric power transmission network to recover from a total or partial shutdown.

The Siemens Energy Sector was one of the four sectors of German industrial conglomerate Siemens. Founded on January 1, 2009, it generated and delivered power from numerous sources including the extraction, conversion and transport of oil and natural gas in addition to renewable and alternative energy sources. As of October 1, 2014, the sector level has been eliminated, including the Siemens Energy Sector.

Croton Dam is an earth-filled embankment dam and powerplant complex on the Muskegon River in Croton Township, Newaygo County, Michigan. It was built in 1907 under the direction of William D. Fargo by the Grand Rapids - Muskegon Power Company, a predecessor of Consumers Energy. The 40-foot-high (12 m) dam impounds 7.2 billion U.S. gallons (6 billion imp. gal/27 billion L) of water in its 1,209-acre (489 ha) reservoir and is capable of producing 8,850 kilowatts at peak outflow. It was listed on the National Register of Historic Places in 1979.

Hydroelectricity is, as of 2019, the second-largest renewable source of energy in both generation and nominal capacity in the United States. In 2021, hydroelectric power produced 31.5% of the total renewable electricity, and 6.3% of the total U.S. electricity.

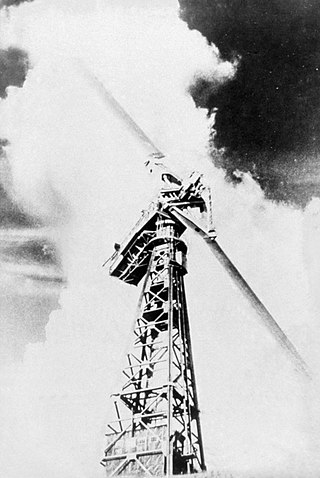

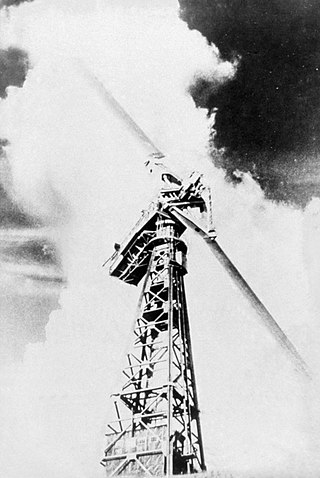

The Smith–Putnam wind turbine was the world's first megawatt-size wind turbine. In 1941 it was connected to the local electrical distribution system on Grandpa's Knob in Castleton, Vermont, US. It was designed by Palmer Cosslett Putnam and manufactured by the S. Morgan Smith Company. The 1.25 MW turbine operated for 1100 hours before a blade failed at a known weak point, which had not been reinforced due to wartime material shortages. It would be the largest wind turbine ever built until 1979.

GE Wind is a division of GE Vernova. The company manufactures and sells wind turbines to the international market. In 2018, GE Wind was the fourth largest wind turbine manufacturer in the world. Vic Abate is the CEO of GE Vernova’s Wind businesses.

Mechanicville Hydroelectric Plant is a 18.3-acre (7.4 ha) national historic district located at Mechanicville in Saratoga County, New York. The listing included one contributing building and three contributing structures. The district dates to 1897 and includes notable Queen Anne architecture.

Ukrainian Energy Machines Joint Stock Company "Turboatom", commonly known as just Turboatom, is a state enterprise responsible for power engineering in Ukraine. The company specializes in the production and maintenance of steam and other turbines for thermal power stations; nuclear power plants and cogeneration plants; hydraulic turbines for hydroelectric power stations and pumped storage power plants; gas turbines and combined cycle turbines for thermal power plants; and other power equipment.

GE Renewable Energy is a manufacturing and services division of the American company General Electric. It is headquartered in Boulogne-Billancourt, near Paris, France and focuses on the production of energy systems that use renewable sources. Its products include wind, hydroelectric and solar power generating facilities.