A jet engine is a type of reaction engine discharging a fast-moving jet that generates thrust by jet propulsion. While this broad definition can include rocket, water jet, and hybrid propulsion, the term jet engine typically refers to an airbreathing jet engine such as a turbojet, turbofan, ramjet, or pulse jet. In general, jet engines are combustion engines.

The turbofan or fanjet is a type of airbreathing jet engine that is widely used in aircraft propulsion. The word "turbofan" is a portmanteau of "turbine" and "fan": the turbo portion refers to a gas turbine engine which achieves mechanical energy from combustion, and the fan, a ducted fan that uses the mechanical energy from the gas turbine to accelerate air rearwards. Thus, whereas all the air taken in by a turbojet passes through the turbine, in a turbofan some of that air bypasses the turbine. A turbofan thus can be thought of as a turbojet being used to drive a ducted fan, with both of these contributing to the thrust.

The aerospike engine is a type of rocket engine that maintains its aerodynamic efficiency across a wide range of altitudes. It belongs to the class of altitude compensating nozzle engines. A vehicle with an aerospike engine uses 25–30% less fuel at low altitudes, where most missions have the greatest need for thrust. Aerospike engines have been studied for a number of years and are the baseline engines for many single-stage-to-orbit (SSTO) designs and were also a strong contender for the Space Shuttle main engine. However, no such engine is in commercial production, although some large-scale aerospikes are in testing phases.

The turbojet is an airbreathing jet engine, typically used in aircraft. It consists of a gas turbine with a propelling nozzle. The gas turbine has an air inlet, a compressor, a combustion chamber, and a turbine. The compressed air from the compressor is heated by burning fuel in the combustion chamber and then allowed to expand through the turbine. The turbine exhaust is then expanded in the propelling nozzle where it is accelerated to high speed to provide thrust. Two engineers, Frank Whittle in the United Kingdom and Hans von Ohain in Germany, developed the concept independently into practical engines during the late 1930s.

The engine configuration describe the fundamental operating principles by which internal combustion engines are categorised.

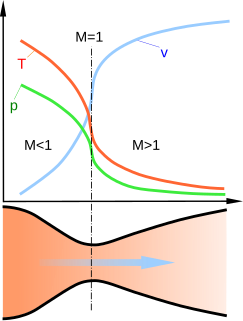

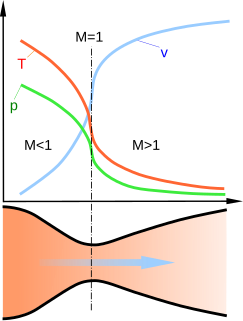

Compressible flow is the branch of fluid mechanics that deals with flows having significant changes in fluid density. While all flows are compressible, flows are usually treated as being incompressible when the Mach number is less than 0.3. The study of compressible flow is relevant to high-speed aircraft, jet engines, rocket motors, high-speed entry into a planetary atmosphere, gas pipelines, commercial applications such as abrasive blasting, and many other fields.

A rocket engine uses stored rocket propellants as the reaction mass for forming a high-speed propulsive jet of fluid, usually high-temperature gas. Rocket engines are reaction engines, producing thrust by ejecting mass rearward, in accordance with Newton's third law. Most rocket engines use the combustion of reactive chemicals to supply the necessary energy, but non-combusting forms such as cold gas thrusters and nuclear thermal rockets also exist. Vehicles propelled by rocket engines are commonly called rockets. Rocket vehicles carry their own oxidizer, unlike most combustion engines, so rocket engines can be used in a vacuum to propel spacecraft and ballistic missiles.

A nozzle is a device designed to control the direction or characteristics of a fluid flow as it exits an enclosed chamber or pipe.

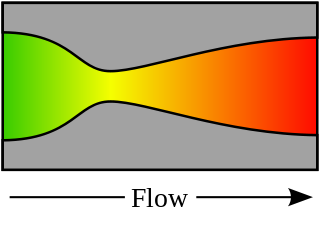

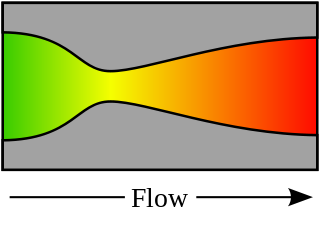

A de Laval nozzle is a tube that is pinched in the middle, making a carefully balanced, asymmetric hourglass shape. It is used to accelerate a hot, pressurized gas passing through it to a higher supersonic speed in the axial (thrust) direction, by converting the heat energy of the flow into kinetic energy. Because of this, the nozzle is widely used in some types of steam turbines and rocket engine nozzles. It also sees use in supersonic jet engines.

Thrust vectoring, also thrust vector control or TVC, is the ability of an aircraft, rocket, or other vehicle to manipulate the direction of the thrust from its engine(s) or motor(s) to control the attitude or angular velocity of the vehicle.

The J-2 was a liquid-fuel cryogenic rocket engine used on NASA's Saturn IB and Saturn V launch vehicles. Built in the U.S. by Rocketdyne, the J-2 burned cryogenic liquid hydrogen (LH2) and liquid oxygen (LOX) propellants, with each engine producing 1,033.1 kN (232,250 lbf) of thrust in vacuum. The engine's preliminary design dates back to recommendations of the 1959 Silverstein Committee. Rocketdyne won approval to develop the J-2 in June 1960 and the first flight, AS-201, occurred on 26 February 1966. The J-2 underwent several minor upgrades over its operational history to improve the engine's performance, with two major upgrade programs, the de Laval nozzle-type J-2S and aerospike-type J-2T, which were cancelled after the conclusion of the Apollo program.

Inlet cones are a component of some supersonic aircraft and missiles. They are primarily used on ramjets, such as the D-21 Tagboard and Lockheed X-7. Some turbojet aircraft including the Su-7, MiG-21, English Electric Lightning, and SR-71 also use an inlet cone.

A propelling nozzle is a nozzle that converts the internal energy of a working gas into propulsive force; it is the nozzle, which forms a jet, that separates a gas turbine, being gas generator, from a jet engine.

A rocket engine nozzle is a propelling nozzle used in a rocket engine to expand and accelerate the combustion gases produced by burning propellants so that the exhaust gases exit the nozzle at hypersonic velocities.

The bell-shaped or contour nozzle is probably the most commonly used shaped rocket engine nozzle. It has a high angle expansion section right behind the nozzle throat; this is followed by a gradual reversal of nozzle contour slope so that at the nozzle exit the divergence angle is small, usually less than a 10 degree half angle.

An altitude compensating nozzle is a class of rocket engine nozzles that are designed to operate efficiently across a wide range of altitudes.

This article briefly describes the components and systems found in jet engines.

An axial turbine is a turbine in which the flow of the working fluid is parallel to the shaft, as opposed to radial turbines, where the fluid runs around a shaft, as in a watermill. An axial turbine has a similar construction as an axial compressor, but it operates in the reverse, converting flow of the fluid into rotating mechanical energy.

The Power Jets WU was a series of three very different experimental jet engines produced and tested by Frank Whittle and his small team in the late 1930s.

Sern or variant may refer to: