Related Research Articles

Spinning is a twisting technique to form yarn from fibers. The fiber intended is drawn out, twisted, and wound onto a bobbin. Originally done by hand using a spindle whorl, the spinning wheel became across Asia and Europe. The spinning jenny and spinning mule, invented in the late 1700s, made mechanical spinning far more efficient than spinning by hand, and made cotton manufacturing one of the centers of the Industrial Revolution.

Wool is the textile fibre obtained from sheep and other animals, including cashmere and mohair from goats, qiviut from muskoxen, hide and fur clothing from bison, angora from rabbits, and other types of wool from camelids.

Yarn is a long continuous length of interlocked fibres, suitable for use in the production of textiles, sewing, crocheting, knitting, weaving, embroidery, or ropemaking. Thread is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or other lubricants to withstand the stresses involved in sewing. Embroidery threads are yarns specifically designed for needlework.

Worsted is a high-quality type of wool yarn, the fabric made from this yarn, and a yarn weight category. The name derives from Worstead, a village in the English county of Norfolk. That village, together with North Walsham and Aylsham, formed a manufacturing centre for yarn and cloth in the 12th century, when pasture enclosure and liming rendered the East Anglian soil too rich for the older agrarian sheep breeds. In the same period, many weavers from the County of Flanders moved to Norfolk. "Worsted" yarns/fabrics are distinct from woollens : the former is considered stronger, finer, smoother, and harder than the latter.

Wool classing is the production of uniform, predictable, low-risk lines of wool, carried out by examining the characteristics of the wool in its raw state and classing (grading) it accordingly. Wool classing is done by a wool classer.

Cashmere wool, usually simply known as cashmere, is a fiber obtained from cashmere goats, pashmina goats, and some other breeds of goat. It has been used to make yarn, textiles and clothing for hundreds of years. Cashmere is closely associated with the Kashmir shawl, the word "cashmere" deriving from an anglicisation of Kashmir, when the Kashmir shawl reached Europe in the 19th century. Both the soft undercoat and the guard hairs may be used; the softer hair is reserved for textiles, while the coarse guard hair is used for brushes and other non-apparel purposes.

Pashmina refers to a fine variant of spun cashmere, the animal-hair fibre forming the downy undercoat of the Changthangi goat. The word pashm means "wool" in Persian, but in Kashmir, pashm referred to the raw unspun wool of domesticated Changthangi goats. In common parlance today, pashmina may refer either to the material or to the variant of the Kashmir shawl that is made from it. Both generic cashmere and pashmina come from the same goat, but generic cashmere ranges from 12 to 21 microns in diameter, whereas pashmina refers only to those fibres that range from 12 to 16 microns.

A shawl is an Indian simple item of clothing, loosely worn over the shoulders, upper body and arms, and sometimes also over the head. It is usually a rectangular or square piece of cloth, which is often folded to make a triangle, but can also be triangular in shape. Other shapes include oblong shawls.

A sheep shearer is a worker who uses (hand-powered)-blade or machine shears to remove wool from domestic sheep during crutching or shearing.

Sheep shearing is the process by which the woollen fleece of a sheep is cut off. The person who removes the sheep's wool is called a shearer. Typically each adult sheep is shorn once each year. The annual shearing most often occurs in a shearing shed, a facility especially designed to process often hundreds and sometimes more than 3,000 sheep per day.

Textile manufacturing is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products. Overall, many things can be made with cotton, not just clothing.

A wool staple is a cluster or lock of wool fibres and not a single fibre.

Alpaca fleece is the natural fiber harvested from an alpaca. There are two different types of alpaca fleece. The most common fleece type comes from a Huacaya. Huacaya fiber grows and looks similar to sheep wool in that the animal looks "fluffy". The second type of alpaca is Suri and makes up less than 10% of the South American alpaca population. Suri fiber is more similar to natural silk and hangs off the body in locks that have a dreadlock appearance. While both fibers can be used in the worsted milling process using light weight yarn or thread, Huacaya fiber can also be used in a woolen process and spun into various weight yarns. It is a soft, durable, luxurious and silky natural fiber.

Minnesota's Shepherd's Harvest Festival is the largest sheep and wool festival in Minnesota.

The Beulah Speckled Face is a breed of domestic sheep originating in the United Kingdom. Having been bred in the uplands of Wales for more than a hundred years, a breed society was officially formed in 1958. This breed is most common in Eppynt, Llanafan Fawr, Abergwesyn, and Llanwrtyd Wells, and it is little known outside Wales. The origins of the breed are unclear; it may be a truly native breed that has been selected to suit the local environment for centuries. The breed is named for its distinctly patterned black and white face, which is free from wool. The ewes, which are naturally polled, are often crossed with lowland rams such as the Suffolk, Texel or Bluefaced Leicester to breed mules, and to produce market lambs for meat. When bred pure, the lambs do not meet today's export demand for lean, fast-growing sheep. However, the ewes make good mothers and produce plenty of milk.

Textile manufacturing is one of the oldest human activities. The oldest known textiles date back to about 5000 B.C. In order to make textiles, the first requirement is a source of fibre from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving to create cloth. The machine used for weaving is the loom. Cloth is finished by what are described as wet process to become fabric. The fabric may be dyed, printed or decorated by embroidering with coloured yarns.

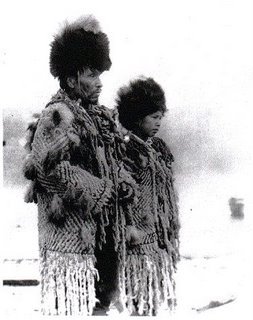

Salish are skilled weavers and knitters of the Pacific Northwest. They are most noted for their beautiful twill blankets many of which are very old. The adoption of new fabrics, dyes, and weaving techniques allow us to study a wide variety of Salish weavings today.

Cowichan knitting is a form of knitting characteristic of the Cowichan people of southeastern Vancouver Island, British Columbia. The distinctively patterned, heavy-knit Cowichan sweaters, popular among British Columbians and tourists, are produced using this method. Cowichan knitting is an acculturated art form, a combination of European textile techniques and Salish spinning and weaving methods. From this union, new tools, techniques and designs developed over the years.

The woollen industry in Wales was at times the country's most important industry, though it often struggled to compete with the better-funded woollen mills in the north of England, and almost disappeared during the 20th century. There is continued demand for quality Welsh woollen products.

Rock Mill Llandysul, in Capel Dewi, Llandysul, Ceredigion, is the last woollen mill in Wales to be powered by a water wheel.

References

- ↑ Jennifer Szweda Jordan (February 3, 2009). "Extreme Crafts: Sheep To Shawl". National Public Radio . Retrieved 2010-05-03.

At a 'Sheep to Shawl' competition teams shear a sheep, spin the fleece and weave it into a shawl...all in just a couple hours. The fastest team wins.

- ↑ International Back to Back Wool Challenge