Engine configuration is an engineering term for the layout of the major components of a reciprocating piston internal combustion engine. These components are the cylinders and crankshafts in particular but also, sometimes, the camshaft(s).

In an internal combustion engine, the cylinder head sits above the cylinders on top of the cylinder block. It closes in the top of the cylinder, forming the combustion chamber. This joint is sealed by a head gasket. In most engines, the head also provides space for the passages that feed air and fuel to the cylinder, and that allow the exhaust to escape. The head can also be a place to mount the valves, spark plugs, and fuel injectors.

Engine tuning is the adjustment or modification of the internal combustion engine or Engine Control Unit (ECU) to yield optimal performance and increase the engine's power output, economy, or durability. These goals may be mutually exclusive; an engine may be de-tuned with respect to output power in exchange for better economy or longer engine life due to lessened stress on engine components.

A timing belt, timing chain, or cambelt is a part of an internal combustion engine that synchronizes the rotation of the crankshaft and the camshaft(s) so that the engine's valves open and close at the proper times during each cylinder's intake and exhaust strokes. In an interference engine the timing belt or chain is also critical to preventing the piston from striking the valves. A timing belt is usually a toothed belt—a drive belt with teeth on the inside surface. A timing chain is a roller chain.

A cylinder is the central working part of a reciprocating engine or pump, the space in which a piston travels. Multiple cylinders are commonly arranged side by side in a bank, or engine block, which is typically cast from aluminum or cast iron before receiving precision machine work. Cylinders may be sleeved or sleeveless. A sleeveless engine may also be referred to as a "parent-bore engine".

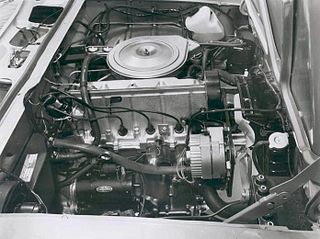

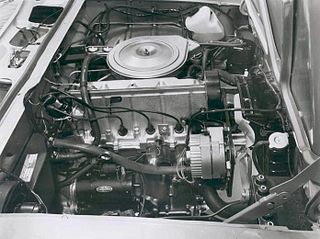

The 2300 is a 2.3 L; 139.6 cu in (2,287 cc) inline-four engine produced by the Chevrolet division of General Motors for the 1971 to 1977 model years of the Chevrolet Vega and Chevrolet Monza. It featured a die-cast aluminum alloy cylinder block. The high-tech block features an alloy with 17 percent silicon. During the machining process, the cylinders were etched leaving the pure silicon particles exposed providing the piston wear surface, eliminating the need for iron cylinder liners. The block has cast iron main caps and a cast iron crankshaft. The engine's cylinder head is cast iron for lower cost, structural integrity and longer camshaft bearing life. The valvetrain features a direct-acting single overhead camshaft design.

An overhead valve engine, or pushrod engine, is a reciprocating piston engine whose poppet valves are situated in the cylinder head. An OHV engine's valvetrain operates its valves via a camshaft within the cylinder block, cam followers, pushrods, and rocker arms.

The powerplant used in Saturn S-series automobiles was a straight-4 aluminum piston engine produced by Saturn, a subsidiary of General Motors. The engine was only used in the Saturn S-series line of vehicles from 1991 through 2002. It was available in chain-driven SOHC or DOHC variants.

The Ford flathead V8 is a V8 engine of the valve-in-block type designed by the Ford Motor Company and built by Ford and various licensees. During the engine's first decade of production, when overhead-valve engines were rare, it was usually known simply as the Ford V‑8, and the first car model in which it was installed, the Model 18, was often called simply the "Ford V‑8", after its new engine. Although the V8 configuration was not new when the Ford V8 was introduced in 1932, the latter was a market first in the respect that it made an 8-cylinder affordable and a V engine affordable to the emerging mass market consumer for the first time. It was the first independently designed and built V8 engine produced by Ford for mass production, and it ranks as one of the company's most important developments. A fascination with ever-more-powerful engines was perhaps the most salient aspect of the American car and truck market for a half century, from 1923 until 1973. The engine was intended to be used for big passenger cars and trucks; it was installed in such until 1953, making the engine's 21-year production run for the U.S. consumer market longer than the 19-year run of the Ford Model T engine for that market. The engine was on Ward's list of the 10 best engines of the 20th century. It was a staple of hot rodders in the 1950s, and it remains famous in the classic car hobbies even today, despite the huge variety of other popular V8s that followed.

Austin Motor Company's small straight-4 automobile engine, the A series, is one of the most common in the world. Launched in 1951 with the Austin A30, production lasted until 2000 in the Mini. It used a cast-iron block and cylinder head, and a steel crankshaft with 3 main bearings. The camshaft ran in the cylinder block, driven by a single-row chain for most applications, and with tappets sliding in the block, accessible through pressed steel side covers for most applications, and with overhead valves operated through rockers. The cylinder head for the overhead-valve version of the A-series engine was designed by Harry Weslake – a cylinder head specialist famed for his involvement in SS (Jaguar) engines and several F1-title winning engines. Although a 'clean sheet' design the A series owed much to established Austin engine design practise, resembling in general design and overall appearance a scaled-down version of the 1200cc overhead-valve engine first seen in the Austin A40 Devon which would form the basis of the later B-series engine.

The BMC C-Series was a straight-6 automobile engine produced from 1954 to 1971. Unlike the Austin-designed A-Series and B-Series engines, it came from the Morris Engines drawing office in Coventry and therefore differed significantly in its layout and design from the two other designs which were closely related. This was due to the C-Series being in essence an enlarged overhead valve development of the earlier 2.2 L Straight-6 overhead camshaft engine used in the post-war Morris Six MS and Wolseley 6/80 from 1948 until 1954, which itself also formed the basis of a related 1.5 L 4-cylinder engine for the Morris Oxford MO in side-valve form and the Wolseley 4/50 in overhead camshaft form. Displacement was 2.6 to 2.9 L with an undersquare stroke of 88.9 mm (3.50 in), bored out to increase capacity.

A tappet is a projection that imparts a linear motion to some other component within a mechanism.

The cam-in-block valvetrain layout of piston engines is one where the camshaft is placed within the cylinder block, usually beside and slightly above the crankshaft in a straight engine or directly above the crankshaft in the V of a V engine. This contrasts with an overhead camshaft (OHC) design which places the camshafts within the cylinder head and drives the valves directly or through short rocker arms.

The Volkswagen wasserboxer is a four cylinder horizontally opposed pushrod overhead-valve (OHV) petrol engine developed by Volkswagen. The engine is water-cooled, and takes its name from the German: "wasserboxer" ("Water-boxer"); with "boxer" being another term for horizontally opposed engines. It was available in two displacements - either a 1.9-litre or a 2.1-litre; the 2.1-litre being a longer stroke version of the 1.9-litre, both variants sharing the same cylinder bore. This engine was unique to the Volkswagen Type 2 (T3), having never been used in any other vehicle. Volkswagen contracted Oettinger to develop a six-cylinder version of this engine. Volkswagen decided not to use it, but Oettinger sold a Volkswagen Type 2 (T3) equipped with this engine.

The Green D.4 was a four-cylinder watercooled inline piston engine produced by the Green Engine Co in the UK in 1909. It produced about 60 hp (45 kW) and played an important role in the development of British aviation before World War I.

The term power assembly refers to an Electro-Motive Diesel (EMD) engine sub-assembly designed to be "easily" removed and replaced in order to restore engine performance lost to wear or engine failure. Typical of heavy-duty internal combustion engines used in industrial applications, EMD engines are designed to allow the cylinder liners, pistons, piston rings and connecting rods to be replaced at overhaul without removing the entire engine assembly from its application location. This increases engine value, reduces downtime and allows the engine to be returned to true new engine performance. Other terms such as cylinder pack, liner pack, cylinder assembly and cylinder kit are used in the engine industry to describe similar assemblies. In the large-engine industry, the term "power assembly" has also become generic and is often used to refer to the assemblies used in non-EMD engines where "power pack" may be the preferred term, although both terms are functionally the same.