A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge used to cut through material. Various terms are used to describe toothed and abrasive saws.

Drill bits are cutting tools used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the shank in the chuck.

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.

A cage nut or caged nut consists of a nut in a spring steel cage which wraps around the nut. The cage has two wings that when compressed allow the cage to be inserted into the square holes, for example, in the mounting rails of equipment racks. When the wings are released, they hold the nut in position behind the hole. Cage nuts conforming to this description were patented in 1952 and 1953. The original design requires an insertion tool to install a cage nut into a hole. Newer designs featuring squeeze-and-release tabs allow for tool-less installation.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

A Howe truss is a truss bridge consisting of chords, verticals, and diagonals whose vertical members are in tension and whose diagonal members are in compression. The Howe truss was invented by William Howe in 1840, and was widely used as a bridge in the mid to late 1800s.

Mechanical screening, often just called screening, is the practice of taking granulated or crushed ore material and separating it into multiple grades by particle size.

Pallet rack is a material handling storage aid system designed to store materials on pallets. Although there are many varieties of pallet racking, all types allow for the storage of palletized materials in horizontal rows with multiple levels. Forklift trucks are usually required to place the loaded pallets onto the racks for storage. Since the Second World War, pallet racks have become a ubiquitous element of most modern warehouses, manufacturing facilities, retail centers, and other storage and distribution facilities. All types of pallet racking increase storage density of the stored goods. Costs associated with the racking increases with increasing storage density.

Notching is a metal-cutting process used on sheet-metal or thin bar-stock, sometimes on angle sections or tube. A shearing or punching process is used in a press, so as to cut vertically down and perpendicular to the surface, working from the edge of a work-piece. Sometimes the goal is merely the notch itself, but usually this is a precursor to some other process: such as bending a corner in sheet or joining two tubes at a tee joint, notching one to fit closely to the other.

A screw is an externally helical threaded fastener capable of being tightened or released by a twisting force (torque) to the head. The most common uses of screws are to hold objects together and there are many forms for a variety of materials. Screws might be inserted into holes in assembled parts or a screw may form its own thread.

A nut is a type of fastener with a threaded hole. Nuts are almost always used in conjunction with a mating bolt to fasten multiple parts together. The two partners are kept together by a combination of their threads' friction, a slight stretching of the bolt, and compression of the parts to be held together.

An ironworker is a tradesman who works in the iron-working industry. Ironworkers assemble the structural framework in accordance with engineered drawings and install the metal support pieces for new buildings. They also repair and renovate old structures using reinforced concrete and steel. Ironworkers may work on factories, steel mills, and utility plants.

Strut channel, often referred to colloquially by one of several manufacturer trade names, is a standardized formed structural system used in the construction and electrical industries for light structural support, often for supporting wiring, plumbing, or mechanical components such as air conditioning or ventilation systems.

A bolt is an externally helical threaded fastener capable of being tightened or released by a twisting force (torque) to a matching nut. The bolt has an external male thread requiring a matching nut with a pre-formed female thread.

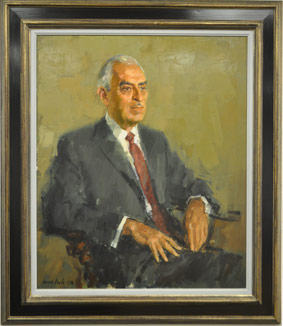

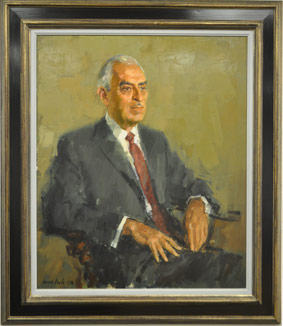

Demetrius Comino OBE was an Australian engineer, inventor, entrepreneur and philanthropist during the 20th century. He invented the slotted angle steel construction system, Dexion, which became widely used internationally for commercial shelving, storage racking, exhibition stands, accommodation, and for domestic purposes. In 1971 he founded the Comino Foundation, an educational charity.

Adjustable shelving allows more flexible use of shelves to hold items of value for storage, display or sale. Like fixed shelves, the horizontal planes are normally made of strong materials such as wood or steel, but their exact vertical positioning can be varied - usually through the use of uprights into which supporting brackets or the shelves themselves can be fixed at different heights.

Dexion is a company name and brand particularly associated with the development of the "Dexion" slotted angle steel strip construction system, widely used since the 1950s for domestic and commercial shelving, storage racking, exhibition stands and accommodation purposes.

Constructor Group AS is a Norwegian-registered international company, with headquarters in Oslo, that specialises in the manufacture and supply of shelving, mobile shelving, pallet racking and similar storage systems, primarily for commercial use in offices, factories, warehouses, museums, archives, libraries and retail outlets.

In library science and architecture, a stack or bookstack is a book storage area, as opposed to a reading area. More specifically, this term refers to a narrow-aisled, multilevel system of iron or steel shelving that evolved in the 19th century to meet increasing demands for storage space. An "open-stack" library allows its patrons to enter the stacks to browse for themselves; "closed stacks" means library staff retrieve books for patrons on request.