Guar gum, also called guaran, is a galactomannan polysaccharide extracted from guar beans that has thickening and stabilizing properties useful in food, feed, and industrial applications. The guar seeds are mechanically dehusked, hydrated, milled and screened according to application. It is typically produced as a free-flowing, off-white powder.

In mining, tailings or tails are the materials left over after the process of separating the valuable fraction from the uneconomic fraction (gangue) of an ore. Tailings are different from overburden, which is the waste rock or other material that overlies an ore or mineral body and is displaced during mining without being processed.

Hydrocyclones are a type of cyclonic separators that separate product phases mainly on basis of differences in gravity with aqueous solutions as the primary feed fluid.

Oil sludge or black sludge is a gel-like or semi-solid deposit inside an internal combustion engine, that can create a catastrophic buildup. It is often the result of contaminated engine oil and occurs when moisture and/or high heat is introduced to engine oil.

A slurry is a mixture of denser solids suspended in liquid, usually water. The most common use of slurry is as a means of transporting solids or separating minerals, the liquid being a carrier that is pumped on a device such as a centrifugal pump. The size of solid particles may vary from 1 micrometre up to hundreds of millimetres. The particles may settle below a certain transport velocity and the mixture can behave like a Newtonian or non-Newtonian fluid. Depending on the mixture, the slurry may be abrasive and/or corrosive.

Agricultural wastewater treatment is a farm management agenda for controlling pollution from confined animal operations and from surface runoff that may be contaminated by chemicals in fertilizer, pesticides, animal slurry, crop residues or irrigation water. Agricultural wastewater treatment is required for continuous confined animal operations like milk and egg production. It may be performed in plants using mechanized treatment units similar to those used for industrial wastewater. Where land is available for ponds, settling basins and facultative lagoons may have lower operational costs for seasonal use conditions from breeding or harvest cycles. Animal slurries are usually treated by containment in anaerobic lagoons before disposal by spray or trickle application to grassland. Constructed wetlands are sometimes used to facilitate treatment of animal wastes.

Industrial wastewater treatment describes the processes used for treating wastewater that is produced by industries as an undesirable by-product. After treatment, the treated industrial wastewater may be reused or released to a sanitary sewer or to a surface water in the environment. Some industrial facilities generate wastewater that can be treated in sewage treatment plants. Most industrial processes, such as petroleum refineries, chemical and petrochemical plants have their own specialized facilities to treat their wastewaters so that the pollutant concentrations in the treated wastewater comply with the regulations regarding disposal of wastewaters into sewers or into rivers, lakes or oceans. This applies to industries that generate wastewater with high concentrations of organic matter, toxic pollutants or nutrients such as ammonia. Some industries install a pre-treatment system to remove some pollutants, and then discharge the partially treated wastewater to the municipal sewer system.

In materials science, the sol–gel process is a method for producing solid materials from small molecules. The method is used for the fabrication of metal oxides, especially the oxides of silicon (Si) and titanium (Ti). The process involves conversion of monomers into a colloidal solution (sol) that acts as the precursor for an integrated network of either discrete particles or network polymers. Typical precursors are metal alkoxides. Sol–gel process is used to produce ceramic nanoparticles.

Powdered Activated Carbon Treatment (PACT) is a wastewater technology in which powdered activated carbon is added to an anaerobic or aerobic treatment system. The carbon in the biological treatment process adsorbs recalcitrant compounds that are not readily biodegradable, thereby reducing the chemical oxygen demand of the wastewater and removing toxins. The carbon also acts as a "buffer" against the effects of toxic organics in the wastewater.

The Martin County coal slurry spill was a mining accident that occurred after midnight on October 11, 2000, when the bottom of a coal slurry impoundment owned by Massey Energy in Martin County, Kentucky, broke into an abandoned underground mine below. The slurry came out of the mine openings, sending an estimated 306 million US gallons of slurry down two tributaries of the Tug Fork River. By morning, Wolf Creek was oozing with the black waste; on Coldwater Fork, a 10-foot-wide (3.0 m) stream became a 100-yard (91 m) expanse of thick slurry.

A lamella clarifier or inclined plate settler (IPS) is a type of clarifier designed to remove particulates from liquids.

Coal slurry is a mixture of solids and liquids produced by a coal preparation plant.

The Kingston Fossil Plant coal fly ash slurry spill was an environmental and industrial disaster that occurred on December 22, 2008, when a dike ruptured at a coal ash pond at the Tennessee Valley Authority's Kingston Fossil Plant in Roane County, Tennessee, releasing 1.1 billion US gallons of coal fly ash slurry. The coal-fired power plant, located across the Clinch River from the city of Kingston, used a series of ponds to store and dewater the fly ash, a byproduct of coal combustion. The spill released a slurry of fly ash and water which traveled across the Emory River and its Swan Pond embayment onto the opposite shore, covering up to 300 acres (1.2 km2) of the surrounding land. The spill damaged multiple homes and flowed into nearby waterways including the Emory River and Clinch River, both tributaries of the Tennessee River. It was the largest industrial spill in United States history.

Coal-water slurry fuel is a combustible mixture of fine coal particles suspended in water. It can be used to power boilers, gas turbines, diesel engines and heating and power stations.

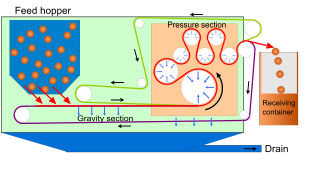

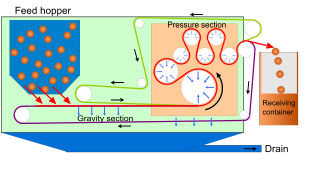

The belt filter is an industrial machine, used for solid/liquid separation processes, particularly the dewatering of sludges in the chemical industry, mining and water treatment. Belt filter presses are also used in the production of apple juice, cider and winemaking. The process of filtration is primarily obtained by passing a pair of filtering cloths and belts through a system of rollers. The system takes a sludge or slurry as a feed, and separates it into a filtrate and a solid cake.

High-density solids pumps are hydrostatically operating machines which displace the medium being pumped and thus create a flow.

A solid bowl centrifuge is a type of centrifuge that uses the principle of sedimentation. A centrifuge is used to separate a mixture that consists of two substances with different densities by using the centrifugal force resulting from continuous rotation. It is normally used to separate solid-liquid, liquid-liquid, and solid-solid mixtures. Solid bowl centrifuges are widely used in various industrial applications, such as wastewater treatment, coal manufacturing, and polymer manufacturing. One advantage of solid bowl centrifuges for industrial uses is the simplicity of installation compared to other types of centrifuge. There are three design types of solid bowl centrifuge, which are conical, cylindrical, and conical-cylindrical.

A conical plate centrifuge is a type of centrifuge that has a series of conical discs which provides a parallel configuration of centrifugation spaces.

Sludge is a semi-solid slurry that can be produced from a range of industrial processes, from water treatment, wastewater treatment or on-site sanitation systems. It can be produced as a settled suspension obtained from conventional drinking water treatment, as sewage sludge from wastewater treatment processes or as fecal sludge from pit latrines and septic tanks. The term is also sometimes used as a generic term for solids separated from suspension in a liquid; this soupy material usually contains significant quantities of interstitial water. Sludge can consist of a variety of particles, such as animal manure.

A water-gel explosive is a fuel sensitized explosive mixture consisting of an aqueous ammonium nitrate solution that acts as the oxidizer. Water gels that are cap-insensitive are referred to under United States safety regulations as blasting agents. Water gel explosives have a jelly-like consistency and come in sausage-like packing stapled shut on both sides.