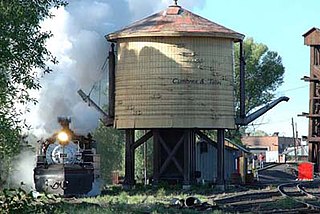

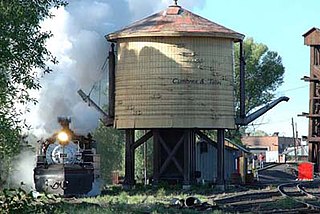

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be transformed, by a connecting rod and crank, into rotational force for work. The term "steam engine" is generally applied only to reciprocating engines as just described, not to the steam turbine. Steam engines are external combustion engines, where the working fluid is separated from the combustion products. The ideal thermodynamic cycle used to analyze this process is called the Rankine cycle. In general usage, the term steam engine can refer to either complete steam plants, such as railway steam locomotives and portable engines, or may refer to the piston or turbine machinery alone, as in the beam engine and stationary steam engine.

Sodium hydroxide, also known as lye and caustic soda, is an inorganic compound with the formula NaOH. It is a white solid ionic compound consisting of sodium cations Na+ and hydroxide anions OH−.

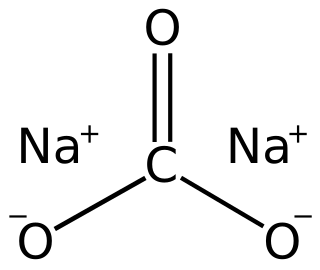

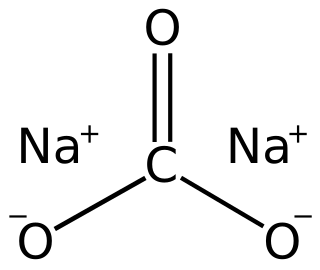

Sodium carbonate, Na2CO3, (also known as washing soda, soda ash and soda crystals) is the inorganic compound with the formula Na2CO3 and its various hydrates. All forms are white, odourless, water-soluble salts that yield moderately alkaline solutions in water. Historically, it was extracted from the ashes of plants growing in sodium-rich soils. Because the ashes of these sodium-rich plants were noticeably different from ashes of wood (once used to produce potash), sodium carbonate became known as "soda ash". It is produced in large quantities from sodium chloride and limestone by the Solvay process.

A boiler is a closed vessel in which fluid is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.

Superheated steam is steam at a temperature higher than its vaporization point at the absolute pressure where the temperature is measured.

The chloralkali process is an industrial process for the electrolysis of sodium chloride (NaCl) solutions. It is the technology used to produce chlorine and sodium hydroxide, which are commodity chemicals required by industry. Thirty five million tons of chlorine were prepared by this process in 1987. The chlorine and sodium hydroxide produced in this process are widely used in the chemical industry.

A high pressure watertube boiler is a type of boiler in which water circulates in tubes heated externally by the fire. Fuel is burned inside the furnace, creating hot gas which boils water in the steam-generating tubes. In smaller boilers, additional generating tubes are separate in the furnace, while larger utility boilers rely on the water-filled tubes that make up the walls of the furnace to generate steam.

Kipp's apparatus, also called Kipp generator, is an apparatus designed for preparation of small volumes of gases. It was invented around 1844 by the Dutch pharmacist Petrus Jacobus Kipp and widely used in chemical laboratories and for demonstrations in schools into the second half of the 20th century.

Alkali manufacture is the process by which an alkali is made. Typical alkalis, produced commercially, include sodium hydroxide, sodium carbonate, potassium hydroxide and potassium carbonate.

Boiler water is liquid water within a boiler, or in associated piping, pumps and other equipment, that is intended for evaporation into steam. The term may also be applied to raw water intended for use in boilers, treated boiler feedwater, steam condensate being returned to a boiler, or boiler blowdown being removed from a boiler.

Boiler feedwater is an essential part of boiler operations. The feed water is put into the steam drum from a feed pump. In the steam drum the feed water is then turned into steam from the heat. After the steam is used it is then dumped to the main condenser. From the condenser it is then pumped to the deaerated feed tank. From this tank it then goes back to the steam drum to complete its cycle. The feed water is never open to the atmosphere. This cycle is known as a closed system or Rankine cycle.

A boiler or steam generator is a device used to create steam by applying heat energy to water. Although the definitions are somewhat flexible, it can be said that older steam generators were commonly termed boilers and worked at low to medium pressure but, at pressures above this, it is more usual to speak of a steam generator.

Chlorine gas can be produced by extracting from natural materials, including the electrolysis of a sodium chloride solution (brine) and other ways.

The dealkalization of water refers to the removal of alkalinity ions from water. Chloride cycle anion ion-exchange dealkalizers remove alkalinity from water.

Steam is a substance containing water in the gas phase, and sometimes also an aerosol of liquid water droplets, or air. This may occur due to evaporation or due to boiling, where heat is applied until water reaches the enthalpy of vaporization. Steam that is saturated or superheated is invisible; however, "steam" often refers to wet steam, the visible mist or aerosol of water droplets formed as water vapor condenses.

The 5 megawatt (MW) Kimberlina Solar Thermal Energy Plant in Bakersfield, California is the first commercial solar thermal power plant to be built by Areva Solar. Completed in 2008, the Kimberlina renewable energy solar boiler uses Compact Linear Fresnel Reflector (CLFR) technology to generate superheated steam. Each solar boiler has a group of 13 narrow, flat mirrors, that individually track and focus the sun's heat onto overhead pipes carrying water. The water boils directly into steam. The steam can then spin a turbine to generate electricity or be used as industrial steam for food, oil and desalination processes. The Kimberlina solar boiler currently achieves 750-degree F superheated steam. The next generation solar boiler under construction is designed to achieve 900-degree F superheated steam.

Caustic embrittlement is the phenomenon in which the material of a boiler becomes brittle due to the accumulation of caustic substances.

Liquid bleach, often called just bleach, is a common chemical household product that consists of a dilute solution of sodium hypochlorite and other secondary ingredients. It is a chlorine releasing bleaching agent widely used to whiten clothes and remove stains, as a disinfectant to kill germs, and for several other uses.

Red Scar Works was built in 1939 by Courtaulds and produced rayon. It was located in Ribbleton Preston off Longridge Road. The closure of the works was announced in November 1979 and the issue raised in the UK Parliament House of Commons by the constituency MP. At the time of closure approximately 2,600 people were employed there but there were approximately 4,000 at its peak. It was the largest rayon producing site in Britain. Two main products were manufactured with one being tyre cord by a process known as CSPT - Continuous Spinning Process Tenasco. Two main denier of this product were manufactured. The other product was a general textile called Bright. A range of deniers of this were produced in a range of colours. The trade name for the coloured product was Duracol. At the time of closure, one reason given by management for the closure was the rising popularity of steel belt radial tires thus reducing demand for tyre cord.