Stainless steel, also known as inox, corrosion-resistant steel (CRES), and rustless steel, is an alloy of iron that is resistant to rusting and corrosion. It contains iron with chromium and other elements such as molybdenum, carbon, nickel and nitrogen depending on its specific use and cost. Stainless steel's resistance to corrosion results from the 10.5%, or more, chromium content which forms a passive film that can protect the material and self-heal in the presence of oxygen.

Heat treating is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. Although the term heat treatment applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding.

Martensite is a very hard form of steel crystalline structure. It is named after German metallurgist Adolf Martens. By analogy the term can also refer to any crystal structure that is formed by diffusionless transformation.

Brazing is a metal-joining process in which two or more metal items are joined by melting and flowing a filler metal into the joint, with the filler metal having a lower melting point than the adjoining metal.

In metallurgy, a shape-memory alloy (SMA) is an alloy that can be deformed when cold but returns to its pre-deformed ("remembered") shape when heated. It is also known in other names such as memory metal, memory alloy, smart metal, smart alloy, and muscle wire. The "memorized geometry" can be modified by fixating the desired geometry and subjecting it to a thermal treatment, for example a wire can be taught to memorize the shape of a coil spring.

A magnetic shape-memory alloy (MSMA) is a type of smart material that can undergo significant and reversible changes in shape in response to a magnetic field. This behavior arises due to a combination of magnetic and shape-memory properties within the alloy, allowing it to produce mechanical motion or force under magnetic actuation. MSMAs are commonly made from ferromagnetic materials, particularly nickel-manganese-gallium (Ni-Mn-Ga), and are useful in applications requiring rapid, controllable, and repeatable movement.

In modern Western body piercing, a wide variety of materials are used. Some cannot be autoclaved, and others may induce allergic reactions, or harbour bacteria. Certain countries, such as those belonging to the EU, have legal regulations specifying which materials can be used in new piercings.

Maraging steels are steels that are known for possessing superior strength and toughness without losing ductility. Aging refers to the extended heat-treatment process. These steels are a special class of very-low-carbon ultra-high-strength steels that derive their strength not from carbon, but from precipitation of intermetallic compounds. The principal alloying element is 15 to 25 wt% nickel. Secondary alloying elements, which include cobalt, molybdenum and titanium, are added to produce intermetallic precipitates.

Tumbaga is the name given by Spanish Conquistadors for a non-specific alloy of gold and copper, and metals composed of these elements. Pieces made of tumbaga were widely found in pre-Columbian Mesoamerica in North America and South America.

Hardening is a metallurgical metalworking process used to increase the hardness of a metal. The hardness of a metal is directly proportional to the uniaxial yield stress at the location of the imposed strain. A harder metal will have a higher resistance to plastic deformation than a less hard metal.

An archwire in orthodontics is a wire conforming to the alveolar or dental arch that can be used with dental braces as a source of force in correcting irregularities in the position of the teeth. An archwire can also be used to maintain existing dental positions; in this case it has a retentive purpose.

In metallurgy and materials science, annealing is a heat treatment that alters the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness, making it more workable. It involves heating a material above its recrystallization temperature, maintaining a suitable temperature for an appropriate amount of time and then cooling.

Alloy steel is steel that is alloyed with a variety of elements in amounts between 1.0% and 50% by weight, typically to improve its mechanical properties.

An aluminium alloy (UK/IUPAC) or aluminum alloy is an alloy in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to the low melting point, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.

In materials science, pseudoelasticity, sometimes called superelasticity, is an elastic (reversible) response to an applied stress, caused by a phase transformation between the austenitic and martensitic phases of a crystal. It is exhibited in shape-memory alloys.

Nickel titanium, also known as nitinol, is a metal alloy of nickel and titanium, where the two elements are present in roughly equal atomic percentages. Different alloys are named according to the weight percentage of nickel; e.g., nitinol 55 and nitinol 60.

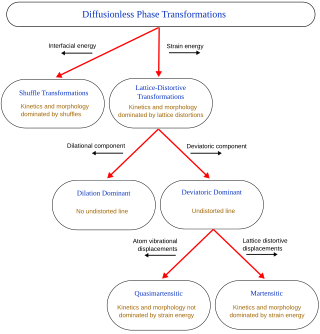

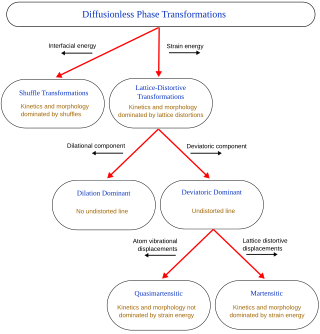

A diffusionless transformation, commonly known as displacive transformation, denotes solid-state alterations in crystal structures that do not hinge on the diffusion of atoms across extensive distances. Rather, these transformations manifest as a result of synchronized shifts in atomic positions, wherein atoms undergo displacements of distances smaller than the spacing between adjacent atoms, all while preserving their relative arrangement. An example of such a phenomenon is the martensitic transformation, a notable occurrence observed in the context of steel materials.

Colored gold is the name given to any gold that has been treated using techniques to change its natural color. Pure gold is slightly reddish yellow in color, but colored gold can come in a variety of different colors by alloying it with different elements.

The R-phase is a phase found in nitinol, a shape-memory alloy. It is a martensitic phase in nature, but is not the martensite that is responsible for the shape memory and superelastic effect.