A jet engine is a type of reaction engine, discharging a fast-moving jet of heated gas that generates thrust by jet propulsion. While this broad definition may include rocket, water jet, and hybrid propulsion, the term jet engine typically refers to an internal combustion air-breathing jet engine such as a turbojet, turbofan, ramjet, pulse jet, or scramjet. In general, jet engines are internal combustion engines.

A rocket is a vehicle that uses jet propulsion to accelerate without using the surrounding air. A rocket engine produces thrust by reaction to exhaust expelled at high speed. Rocket engines work entirely from propellant carried within the vehicle; therefore a rocket can fly in the vacuum of space. Rockets work more efficiently in a vacuum and incur a loss of thrust due to the opposing pressure of the atmosphere.

A ramjet is a form of airbreathing jet engine that requires forward motion of the engine to provide air for combustion. Ramjets work most efficiently at supersonic speeds around Mach 3 and can operate up to Mach 6.

A turbofan or fanjet is a type of airbreathing jet engine that is widely used in aircraft propulsion. The word "turbofan" is a combination of the preceding generation engine technology of the turbojet, and a reference to the additional fan stage added. It consists of a gas turbine engine which achieves mechanical energy from combustion, and a ducted fan that uses the mechanical energy from the gas turbine to force air rearwards. Thus, whereas all the air taken in by a turbojet passes through the combustion chamber and turbines, in a turbofan some of that air bypasses these components. A turbofan thus can be thought of as a turbojet being used to drive a ducted fan, with both of these contributing to the thrust.

The aerospike engine is a type of rocket engine that maintains its aerodynamic efficiency across a wide range of altitudes. It belongs to the class of altitude compensating nozzle engines. Aerospike engines were proposed for many single-stage-to-orbit (SSTO) designs. They were a contender for the Space Shuttle main engine. However, as of 2023 no such engine was in commercial production, although some large-scale aerospikes were in testing phases.

The plug nozzle is a type of nozzle which includes a centerbody or plug around which the working fluid flows. Plug nozzles have applications in aircraft, rockets, and numerous other fluid flow devices.

The expanding nozzle is a type of rocket nozzle that, unlike traditional designs, maintains its efficiency at a wide range of altitudes. It is a member of the class of altitude compensating nozzles, a class that also includes the plug nozzle and aerospike. While the expanding nozzle is the least technically advanced and simplest to understand from a modeling point of view, it also appears to be the most difficult design to build.

The turbojet is an airbreathing jet engine which is typically used in aircraft. It consists of a gas turbine with a propelling nozzle. The gas turbine has an air inlet which includes inlet guide vanes, a compressor, a combustion chamber, and a turbine. The compressed air from the compressor is heated by burning fuel in the combustion chamber and then allowed to expand through the turbine. The turbine exhaust is then expanded in the propelling nozzle where it is accelerated to high speed to provide thrust. Two engineers, Frank Whittle in the United Kingdom and Hans von Ohain in Germany, developed the concept independently into practical engines during the late 1930s.

A scramjet is a variant of a ramjet airbreathing jet engine in which combustion takes place in supersonic airflow. As in ramjets, a scramjet relies on high vehicle speed to compress the incoming air forcefully before combustion, but where as a ramjet decelerates the air to subsonic velocities before combustion using shock cones, a scramjet has no shock cone and slows the airflow using shockwaves produced by its ignition source in place of a shock cone. This allows the scramjet to operate efficiently at extremely high speeds.

A rocket engine uses stored rocket propellants as the reaction mass for forming a high-speed propulsive jet of fluid, usually high-temperature gas. Rocket engines are reaction engines, producing thrust by ejecting mass rearward, in accordance with Newton's third law. Most rocket engines use the combustion of reactive chemicals to supply the necessary energy, but non-combusting forms such as cold gas thrusters and nuclear thermal rockets also exist. Vehicles propelled by rocket engines are commonly used by ballistic missiles and rockets. Rocket vehicles carry their own oxidiser, unlike most combustion engines, so rocket engines can be used in a vacuum to propel spacecraft and ballistic missiles.

An afterburner is an additional combustion component used on some jet engines, mostly those on military supersonic aircraft. Its purpose is to increase thrust, usually for supersonic flight, takeoff, and combat. The afterburning process injects additional fuel into a combustor in the jet pipe behind the turbine, "reheating" the exhaust gas. Afterburning significantly increases thrust as an alternative to using a bigger engine with its attendant weight penalty, but at the cost of increased fuel consumption which limits its use to short periods. This aircraft application of "reheat" contrasts with the meaning and implementation of "reheat" applicable to gas turbines driving electrical generators and which reduces fuel consumption.

Thrust vectoring, also known as thrust vector control (TVC), is the ability of an aircraft, rocket or other vehicle to manipulate the direction of the thrust from its engine(s) or motor(s) to control the attitude or angular velocity of the vehicle.

SABRE is a concept under development by Reaction Engines Limited for a hypersonic precooled hybrid air-breathing rocket engine. The engine is being designed to achieve single-stage-to-orbit capability, propelling the proposed Skylon spaceplane to low Earth orbit. SABRE is an evolution of Alan Bond's series of LACE-like designs that started in the early/mid-1980s for the HOTOL project.

A jet pack, rocket belt, rocket pack or flight pack is a device worn as a backpack which uses jets to propel the wearer through the air. The concept has been present in science fiction for almost a century and the first working experimental devices were demonstrated in the 1960s.

The Pratt & Whitney J58 is an American jet engine that powered the Lockheed A-12, and subsequently the YF-12 and the SR-71 aircraft. It was an afterburning turbojet engine with a unique compressor bleed to the afterburner that gave increased thrust at high speeds. Because of the wide speed range of the aircraft, the engine needed two modes of operation to take it from stationary on the ground to 2,000 mph (3,200 km/h) at altitude. It was a conventional afterburning turbojet for take-off and acceleration to Mach 2 and then used permanent compressor bleed to the afterburner above Mach 2. The way the engine worked at cruise led it to be described as "acting like a turboramjet". It has also been described as a turboramjet based on incorrect statements describing the turbomachinery as being completely bypassed.

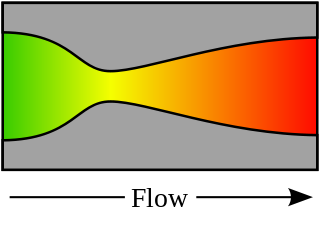

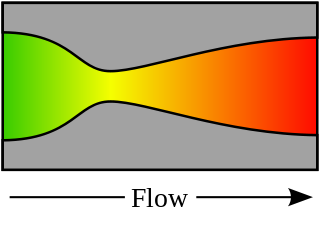

A propelling nozzle is a nozzle that converts the internal energy of a working gas into propulsive force; it is the nozzle, which forms a jet, that separates a gas turbine, or gas generator, from a jet engine.

A compressor map is a chart which shows the performance of a turbomachinery compressor. This type of compressor is used in gas turbine engines, for supercharging reciprocating engines and for industrial processes, where it is known as a dynamic compressor. A map is created from compressor rig test results or predicted by a special computer program. Alternatively the map of a similar compressor can be suitably scaled. This article is an overview of compressor maps and their different applications and also has detailed explanations of maps for a fan and intermediate and high-pressure compressors from a three-shaft aero-engine as specific examples.

A rocket engine nozzle is a propelling nozzle used in a rocket engine to expand and accelerate combustion products to high supersonic velocities.

An altitude compensating nozzle is a class of rocket engine nozzles that are designed to operate efficiently across a wide range of altitudes.

The expansion-deflection nozzle is a rocket nozzle which achieves altitude compensation through interaction of the exhaust gas with the atmosphere, much like the plug and aerospike nozzles.