Related Research Articles

In commerce, supply chain management (SCM) deals with a system of procurement, operations management, logistics and marketing channels so that the raw materials can be converted into a finished product and delivered to the end customer. A more narrow definition of the supply chain management is the "design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronising supply with demand and measuring performance globally".This can include the movement and storage of raw materials, work-in-process inventory, finished goods, and end to end order fulfilment from the point of origin to the point of consumption. Interconnected, interrelated or interlinked networks, channels and node businesses combine in the provision of products and services required by end customers in a supply chain.

A business model describes how an organization creates, delivers, and captures value, in economic, social, cultural or other contexts. The process of business model construction and modification is also called business model innovation and forms a part of business strategy.

A supply chain is a complex logistics system that consists of facilities that convert raw materials into finished products which are later distributed to end consumers or end customers. Meanwhile, supply chain management deals with the flow of goods within the supply chain in the most efficient manner.

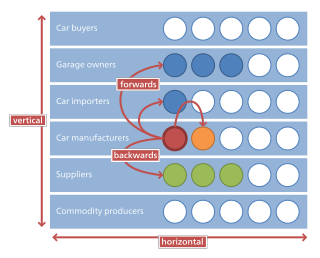

In microeconomics, management and international political economy, vertical integration is a term that describes the arrangement in which the supply chain of a company is integrated and owned by that company. Usually each member of the supply chain produces a different product or (market-specific) service, and the products combine to satisfy a common need. It contrasts with horizontal integration, wherein a company produces several items that are related to one another. Vertical integration has also described management styles that bring large portions of the supply chain not only under a common ownership but also into one corporation.

Collaboration is the process of two or more people, entities or organizations working together to complete a task or achieve a goal. Collaboration is similar to cooperation. Most collaboration requires leadership, although the form of leadership can be social within a decentralized and egalitarian group. Teams that work collaboratively often access greater resources, recognition and rewards when facing competition for finite resources.

Procurement is the method of discovering and agreeing to terms and purchasing goods, services, or other works from an external source, often with the use of a tendering or competitive bidding process. The term may also refer to a contractual obligation to "procure", i.e. to "ensure" that something is done. When a government agency buys goods or services through this practice, it is referred to as government procurement or public procurement.

A business alliance is an agreement between businesses, usually motivated by cost reduction and improved service for the customer. Alliances are often bounded by a single agreement with equitable risk and opportunity share for all parties involved and are typically managed by an integrated project team. An example of this is code sharing in airline alliances.

A strategic partnership is a relationship between two commercial enterprises, usually formalized by one or more business contracts. A strategic partnership will usually fall short of a legal partnership entity, agency, or corporate affiliate relationship. Strategic partnerships can take on various forms from shake hand agreements, contractual cooperation's all the way to equity alliances, either the formation of a joint venture or cross-holdings in each other.

Reverse logistics encompasses all operations related to the upstream movement of products and materials. It is "the process of moving goods from their typical final destination for the purpose of capturing value, or proper disposal. Remanufacturing and refurbishing activities also may be included in the definition of reverse logistics." Growing green concerns and advancement of green supply chain management concepts and practices make it all the more relevant. The number of publications on the topic of reverse logistics have increased significantly over the past two decades. The first use of the term "reverse logistics" in a publication was by James R. Stock in a White Paper titled "Reverse Logistics," published by the Council of Logistics Management in 1992. The concept was further refined in subsequent publications by Stock (1998) in another Council of Logistics Management book, titled Development and Implementation of Reverse Logistics Programs, and by Rogers and Tibben-Lembke (1999) in a book published by the Reverse Logistics Association titled Going Backwards: Reverse Logistics Trends and Practices. The reverse logistics process includes the management and the sale of surplus as well as returned equipment and machines from the hardware leasing business. Normally, logistics deal with events that bring the product towards the customer. In the case of reverse logistics, the resource goes at least one step back in the supply chain. For instance, goods move from the customer to the distributor or to the manufacturer.

Supplier relationship management (SRM) is the systematic, enterprise-wide assessment of suppliers’ strengths, performance and capabilities with respect to overall business strategy, determination of what activities to engage in with different suppliers, and planning and execution of all interactions with suppliers, in a coordinated fashion across the relationship life cycle, to maximize the value realized through those interactions. The focus of SRM is to develop two-way, mutually beneficial relationships with strategic supply partners to deliver greater levels of innovation and competitive advantage than could be achieved by operating independently or through a traditional, transaction purchasing arrangement. Underpinning disciplines which support effective SRM includes supplier information management, compliance, risk management and performance management.

Open innovation is a term used to promote an information age mindset toward innovation that runs counter to the secrecy and silo mentality of traditional corporate research labs. The benefits and driving forces behind increased openness have been noted and discussed as far back as the 1960s, especially as it pertains to interfirm cooperation in R&D. Use of the term 'open innovation' in reference to the increasing embrace of external cooperation in a complex world has been promoted in particular by Henry Chesbrough, adjunct professor and faculty director of the Center for Open Innovation of the Haas School of Business at the University of California, and Maire Tecnimont Chair of Open Innovation at Luiss.

Sales and operations planning (S&OP) is an integrated business management process through which the executive/leadership team continually achieves focus, alignment, and synchronization among all organization functions. The S&OP process includes an updated forecast that leads to a sales plan, production plan, inventory plan, customer lead time (backlog) plan, new product development plan, strategic initiative plan, and resulting financial plan. Plan frequency and planning horizon depend on the specifics of the context. Short product life cycles and high demand volatility require a tighter S&OP than steadily consumed products. Done well, the S&OP process also enables effective supply chain management.

Netchain analysis is a theoretical concept integrating supply chain management and network analysis which was introduced by Lazzarini, Chaddad and Cook in 2001. While supply chain analysis focuses on vertical and network analysis on horizontal interdependencies across companies, netchain analysis incorporates both type of interdependencies into one concept. Netchain analysis emphasizes value creation and coordination mechanism sources corresponding to different kind of interdependencies. In practice, netchain analysis is often used in a more general way referring to the perspective that takes into account chain and network characteristics as well. However, it differs in the focus and in the tools used from network science.

This article outlines the evolution of management systems. A management system is the framework of processes and procedures used to ensure that an organization can fulfill all tasks required to achieve its objectives.

Co-opetition or coopetition – simultaneous competition and cooperation – is an important philosophy or strategy that goes beyond the conventional rules of competition and cooperation to achieve advantages of both. Global co-opetition, an application of co-opetition in a global context, is first systematically addressed in Luo’s (2004) book “Coopetition in international business”. According to this book, global co-opetition refers to the simultaneous competition and cooperation between multinational enterprises (MNEs) and their geographically dispersed business stakeholders such as global rivals, global suppliers, global distributors, global alliance partners, and foreign governments as well as among foreign subsidiaries within an MNE.

In commerce, global supply-chain management is defined as the distribution of goods and services throughout a trans-national companies' global network to maximize profit and minimize waste. Essentially, global supply chain-management is the same as supply-chain management, but it focuses on companies and organizations that are trans-national.

Process Risk is considered to be a sub-component of operational risk. It exists when the process that supports a business activity lacks both efficiency and effectiveness, which may then lead to financial, customer, and reputational loss. This form of risk may be present within any stage of a business transaction. For instance, an error in pricing may be seen as loss in sales revenue, while a disruption in the fulfillment process may cause financial losses in terms of production quality and customer relationships. The majority of operational risk events occur due to losses from ineffective processing of business transactions or process management, and from inadequate relations with trade counter parties and vendors.

Panos (Panagiotis) Kouvelis is the Emerson Distinguished Professor of Supply Chain, Operations, and Technology and director of The Boeing Center for Supply Chain Innovation at the Olin Business School at Washington University in St. Louis. He is best known for his work on supply chain management, supply chain finance, operational excellence, and risk management.

Robert Sroufe is a scholar of sustainability, integrated management, high-performance buildings, supply chain management and operations. He is the Murrin Chair of Global Competitiveness at Duquesne University and the Palumbo-Donahue Graduate School of Business. His research utilizes a systemic outlook to understand the triple bottom line performance metrics reported to internal and external stakeholders. More specifically, he focuses on what the most successful systems and tools for measuring and managing the relationship between performance and environmental, social and financial practices of businesses. His list of publications are primarily about: how firms can create productive management systems, integrate them across business functions, and measure and manage their performance; the main drivers of sustainability; the process and importance of existing buildings becoming high-performance buildings; UN Sustainable Development Goals; and the strategic change process that occurs during a firms sustainable development. His Ph.D. was conferred by Michigan State University.

In business administration, desorptive capacity has been defined as "an organization’s ability to identify technology transfer opportunities based on a firm’s outward technology transfer strategy and to facilitate the technology’s application at the recipient". It is considered as a complement to absorptive capacity, and it may be a driver of a successful knowledge transfer.

References

- ↑ Cao, Mei; Zhang, Qingyu (2011-03-01). "Supply chain collaboration: Impact on collaborative advantage and firm performance". Journal of Operations Management. 29 (3): 163–180. doi:10.1016/j.jom.2010.12.008.

- ↑ Togar M. Simatupang; Ramaswami Sridharan (2008-06-06). "Design for supply chain collaboration". Business Process Management Journal. 14 (3): 401–418. doi:10.1108/14637150810876698. ISSN 1463-7154.

- ↑ Chan, Felix T. S.; Prakash, Anuj (2012-08-15). "Inventory management in a lateral collaborative manufacturing supply chain: a simulation study". International Journal of Production Research. 50 (16): 4670–4685. doi:10.1080/00207543.2011.628709. hdl: 10397/25934 . ISSN 0020-7543. S2CID 108465493.

- ↑ "Vizibl | What Is Supplier Collaboration?". www.vizibl.co. Retrieved 2022-06-07.

- 1 2 Goffin, Keith; Lemke, Fred; Szwejczewski, Marek (2006-01-01). "An exploratory study of 'close' supplier–manufacturer relationships". Journal of Operations Management. 24 (2): 189–209. doi:10.1016/j.jom.2005.05.003. hdl: 1826/2117 .

- ↑ Solaimani, S. and van der Veen, J. (2021), "Open supply chain innovation: an extended view on supply chain collaboration", Supply Chain Management, Vol. ahead-of-print No. ahead-of-print. https://doi.org/10.1108/SCM-09-2020-0433

- ↑ Tsay, Andy A. (1999-10-01). "The Quantity Flexibility Contract and Supplier-Customer Incentives". Management Science. 45 (10): 1339–1358. doi:10.1287/mnsc.45.10.1339. ISSN 0025-1909.

- 1 2 Cao, Mei; Vonderembse, Mark A.; Zhang, Qingyu; Ragu-Nathan, T. S. (2010-11-15). "Supply chain collaboration: conceptualisation and instrument development". International Journal of Production Research. 48 (22): 6613–6635. doi:10.1080/00207540903349039. ISSN 0020-7543. S2CID 110513173.

- ↑ Togar M. Simatupang; Ramaswami Sridharan (2005-12-01). "An integrative framework for supply chain collaboration". The International Journal of Logistics Management. 16 (2): 257–274. doi:10.1108/09574090510634548. ISSN 0957-4093.

- ↑ Malhotra, Arvind; Gosain, Sanjay; Sawy, Omar A. El (2005-01-01). "Absorptive Capacity Configurations in Supply Chains: Gearing for Partner-Enabled Market Knowledge Creation". MIS Quarterly. 29 (1): 145–187. doi:10.2307/25148671. JSTOR 25148671.