In meteorology, an anemometer is a device that measures wind speed and direction. It is a common instrument used in weather stations. The earliest known description of an anemometer was by Italian architect and author Leon Battista Alberti (1404–1472) in 1450.

A viscometer is an instrument used to measure the viscosity of a fluid. For liquids with viscosities which vary with flow conditions, an instrument called a rheometer is used. Thus, a rheometer can be considered as a special type of viscometer. Viscometers can measure only constant viscosity, that is, viscosity that does not change with flow conditions.

Flow measurement is the quantification of bulk fluid movement. Flow can be measured using devices called flowmeters in various ways. The common types of flowmeters with industrial applications are listed below:

Time of flight (ToF) is the measurement of the time taken by an object, particle or wave to travel a distance through a medium. This information can then be used to measure velocity or path length, or as a way to learn about the particle or medium's properties. The traveling object may be detected directly or indirectly. Time of flight technology has found valuable applications in the monitoring and characterization of material and biomaterials, hydrogels included.

A rheometer is a laboratory device used to measure the way in which a viscous fluid flows in response to applied forces. It is used for those fluids which cannot be defined by a single value of viscosity and therefore require more parameters to be set and measured than is the case for a viscometer. It measures the rheology of the fluid.

Elastic recoil detection analysis (ERDA), also referred to as forward recoil scattering, is an ion beam analysis technique in materials science to obtain elemental concentration depth profiles in thin films. This technique is known by several different names. These names are listed below. In the technique of ERDA, an energetic ion beam is directed at a sample to be characterized and there is an elastic nuclear interaction between the ions of beam and the atoms of the target sample. Such interactions are commonly of Coulomb nature. Depending on the kinetics of the ions, cross section area, and the loss of energy of the ions in the matter, ERDA helps determine the quantification of the elemental analysis. It also provides information about the depth profile of the sample.

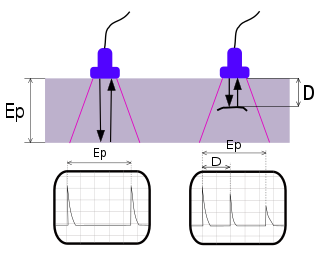

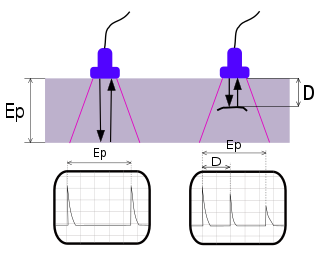

An ultrasonic flow meter is a type of flow meter that measures the velocity of a fluid with ultrasound to calculate volume flow. Using ultrasonic transducers, the flow meter can measure the average velocity along the path of an emitted beam of ultrasound, by averaging the difference in measured transit time between the pulses of ultrasound propagating into and against the direction of the flow or by measuring the frequency shift from the Doppler effect. Ultrasonic flow meters are affected by the acoustic properties of the fluid and can be impacted by temperature, density, viscosity and suspended particulates depending on the exact flow meter. They vary greatly in purchase price but are often inexpensive to use and maintain because they do not use moving parts, unlike mechanical flow meters.

Laser-ultrasonics uses lasers to generate and detect ultrasonic waves. It is a non-contact technique used to measure materials thickness, detect flaws and carry out materials characterization. The basic components of a laser-ultrasonic system are a generation laser, a detection laser and a detector.

Ultrasonic testing (UT) is a family of non-destructive testing techniques based on the propagation of ultrasonic waves in the object or material tested. In most common UT applications, very short ultrasonic pulse waves with centre frequencies ranging from 0.1-15 MHz and occasionally up to 50 MHz, are transmitted into materials to detect internal flaws or to characterize materials. A common example is ultrasonic thickness measurement, which tests the thickness of the test object, for example, to monitor pipework corrosion and erosion. Ultrasonic testing is extensively used to detect flaws in welds.

Doppler echocardiography is a procedure that uses Doppler ultrasonography to examine the heart. An echocardiogram uses high frequency sound waves to create an image of the heart while the use of Doppler technology allows determination of the speed and direction of blood flow by utilizing the Doppler effect.

Curing is a chemical process employed in polymer chemistry and process engineering that produces the toughening or hardening of a polymer material by cross-linking of polymer chains. Even if it is strongly associated with the production of thermosetting polymers, the term "curing" can be used for all the processes where a solid product is obtained from a liquid solution, such as with PVC plastisols.

A scanning acoustic microscope (SAM) is a device which uses focused sound to investigate, measure, or image an object. It is commonly used in failure analysis and non-destructive evaluation. It also has applications in biological and medical research. The semiconductor industry has found the SAM useful in detecting voids, cracks, and delaminations within microelectronic packages.

In granulometry, the particle-size distribution (PSD) of a powder, or granular material, or particles dispersed in fluid, is a list of values or a mathematical function that defines the relative amount, typically by mass, of particles present according to size. Significant energy is usually required to disintegrate soil, etc. particles into the PSD that is then called a grain size distribution.

Picosecond ultrasonics is a type of ultrasonics that uses ultra-high frequency ultrasound generated by ultrashort light pulses. It is a non-destructive technique in which picosecond acoustic pulses penetrate into thin films or nanostructures to reveal internal features such as film thickness as well as cracks, delaminations and voids. It can also be used to probe liquids. The technique is also referred to as picosecond laser ultrasonics or laser picosecond acoustics.

Helium atom scattering (HAS) is a surface analysis technique used in materials science. It provides information about the surface structure and lattice dynamics of a material by measuring the diffracted atoms from a monochromatic helium beam incident on the sample.

SRAS a non-destructive acoustic microscopy microstructural-crystallographic characterization technique commonly used in the study of crystalline or polycrystalline materials. The technique can provide information about the structure and crystallographic orientation of the material. Traditionally, the information provided by SRAS has been acquired by using diffraction techniques in electron microscopy - such as EBSD. The technique was patented in 2005, EP patent 1910815.

Length measurement, distance measurement, or range measurement (ranging) refers to the many ways in which length, distance, or range can be measured. The most commonly used approaches are the rulers, followed by transit-time methods and the interferometer methods based upon the speed of light.

Atomic force acoustic microscopy (AFAM) is a type of scanning probe microscopy (SPM). It is a combination of acoustics and atomic force microscopy. The principal difference between AFAM and other forms of SPM is the addition of a transducer at the bottom of the sample which induces longitudinal out-of-plane vibrations in the specimen. These vibrations are sensed by a cantilever and tip called a probe. The figure shown here is the clear schematic of AFAM principle here B is the magnified version of the tip and sample placed on the transducer and tip having some optical coating generally gold coating to reflect the laser light on to the photodiode.

Resonant ultrasound spectroscopy (RUS) is a laboratory technique used in geology and material science to measure fundamental material properties involving elasticity. This technique relies on the fact that solid objects have natural frequencies at which they vibrate when mechanically excited. The natural frequency depends on the elasticity, size, and shape of the object—RUS exploits this property of solids to determine the elastic tensor of the material. The great advantage of this technique is that the entire elastic tensor is obtained from a single crystal sample in a single rapid measurement. At lower or more general frequencies, this method is known as acoustic resonance spectroscopy.

Active thermography is an advanced nondestructive testing procedure, which uses a thermography measurement of a tested material thermal response after its external excitation. This principle can be used also for non-contact infrared non-destructive testing (IRNDT) of materials.