Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing. Just-in-time manufacturing tries to match production to demand by only supplying goods which have been ordered and focuses on efficiency, productivity, and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow, and throughput times by further eliminating activities which do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service.

Kaizen is a concept referring to business activities that continuously improve all functions and involve all employees from the CEO to the assembly line workers. Kaizen also applies to processes, such as purchasing and logistics, that cross organizational boundaries into the supply chain. It has been applied in healthcare, psychotherapy, life coaching, government, manufacturing, and banking.

The Toyota Production System (TPS) is an integrated socio-technical system, developed by Toyota, that comprises its management philosophy and practices. The TPS is a management system that organizes manufacturing and logistics for the automobile manufacturer, including interaction with suppliers and customers. The system is a major precursor of the more generic "lean manufacturing". Taiichi Ohno and Eiji Toyoda, Japanese industrial engineers, developed the system between 1948 and 1975.

Experiential education is a philosophy of education that describes the process that occurs between a teacher and student that infuses direct experience with the learning environment and content. The term is not interchangeable with experiential learning; however experiential learning is a sub-field and operates under the methodologies of experiential education. The Association for Experiential Education regards experiential education as "a philosophy that informs many methodologies in which educators purposefully engage with learners in direct experience and focused reflection in order to increase knowledge, develop skills, clarify values, and develop people's capacity to contribute to their communities". Experiential education is the term for the philosophy and educational progressivism is the movement which it informed. The Journal of Experiential Education publishes peer-reviewed empirical and theoretical academic research within the field.

PDCA or plan–do–check–act is an iterative design and management method used in business for the control and continual improvement of processes and products. It is also known as the Shewhart cycle, or the control circle/cycle. Another version of this PDCA cycle is OPDCA. The added "O" stands for observation or as some versions say: "Observe the current condition." This emphasis on observation and current condition has currency with the literature on lean manufacturing and the Toyota Production System. The PDCA cycle, with Ishikawa's changes, can be traced back to S. Mizuno of the Tokyo Institute of Technology in 1959.

Lean thinking is a management framework made up of a philosophy, practices and principles which aim to help practitioners improve efficiency and the quality of work. Lean thinking encourages whole organisation participation. The goal is to organise human activities to deliver more benefits to society and value to individuals while eliminating waste.

Reflective practice is the ability to reflect on one's actions so as to take a critical stance or attitude towards one's own practice and that of one's peers, engaging in a process of continuous adaptation and learning. According to one definition it involves "paying critical attention to the practical values and theories which inform everyday actions, by examining practice reflectively and reflexively. This leads to developmental insight". A key rationale for reflective practice is that experience alone does not necessarily lead to learning; deliberate reflection on experience is essential.

Kata is a Japanese word meaning "form". It refers to a detailed choreographed pattern of martial arts movements made to be practiced alone. It can also be reviewed within groups and in unison when training. It is practiced in Japanese martial arts as a way to memorize and perfect the movements being executed. Korean martial arts with Japanese influence use the derived term hyeong and also the term pumsae.

Value-stream mapping, also known as material- and information-flow mapping, is a lean-management method for analyzing the current state and designing a future state for the series of events that take a product or service from the beginning of the specific process until it reaches the customer. A value stream map is a visual tool that displays all critical steps in a specific process and easily quantifies the time and volume taken at each stage. Value stream maps show the flow of both materials and information as they progress through the process.

Practice is the act of rehearsing a behavior repeatedly, to help learn and eventually master a skill. The word derives from the Greek "πρακτική" (praktike), feminine of "πρακτικός" (praktikos), "fit for or concerned with action, practical", and that from the verb "πράσσω" (prasso), "to achieve, bring about, effect, accomplish".

Lean IT is the extension of lean manufacturing and lean services principles to the development and management of information technology (IT) products and services. Its central concern, applied in the context of IT, is the elimination of waste, where waste is work that adds no value to a product or service.

Mike Rother is an American researcher. He introduced the widespread business practices of Value Stream Mapping and Toyota Kata. He has been affiliated with the Industrial Technology Institute, the University of Michigan College of Engineering, the Fraunhofer Institute for Manufacturing Engineering and Automation (Stuttgart), and the Technical University Dortmund.

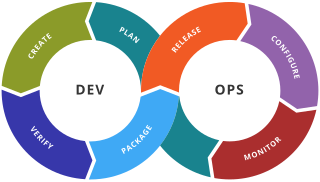

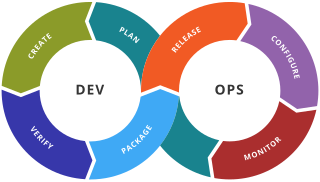

DevOps is a methodology in the software development and IT industry. Used as a set of practices and tools, DevOps integrates and automates the work of software development (Dev) and IT operations (Ops) as a means for improving and shortening the systems development life cycle.

Continuous delivery (CD) is a software engineering approach in which teams produce software in short cycles, ensuring that the software can be reliably released at any time and, following a pipeline through a "production-like environment", without doing so manually. It aims at building, testing, and releasing software with greater speed and frequency. The approach helps reduce the cost, time, and risk of delivering changes by allowing for more incremental updates to applications in production. A straightforward and repeatable deployment process is important for continuous delivery.

Disciplined agile delivery (DAD) is the software development portion of the Disciplined Agile Toolkit. DAD enables teams to make simplified process decisions around incremental and iterative solution delivery. DAD builds on the many practices espoused by advocates of agile software development, including scrum, agile modeling, lean software development, and others.

BuildMaster is an application release automation tool, designed by the software development team Inedo. It combines build management and ARA capabilities to manage and automate processes primarily related to continuous integration, database change scripts, and production deployments, overall releasing applications reliably. The tool is browser-based and able to be used "out-of-the-box". Its feature set and scope puts it in line with the DevOps movement, and is marketed as "more than a release automatigs together the people, processes, and practices that allow teams to deliver software rapidly, reliably, and responsibly.” It's a tool that embodies incremental DevOps adoption.

A DevOps toolchain is a set or combination of tools that aid in the delivery, development, and management of software applications throughout the systems development life cycle, as coordinated by an organisation that uses DevOps practices.

The visual workplace is a continuous improvement paradigm that is closely related to lean manufacturing, the Toyota Production System (TPS), and operational excellence yet offers its own comprehensive methodology that aims for significant financial and cultural improvement gains. Introduced by Gwendolyn Galsworth in her 1997 book Visual Systems, this system integrates and codifies the many iterations of visuality in the world of continuous improvement.

DataOps is a set of practices, processes and technologies that combines an integrated and process-oriented perspective on data with automation and methods from agile software engineering to improve quality, speed, and collaboration and promote a culture of continuous improvement in the area of data analytics. While DataOps began as a set of best practices, it has now matured to become a new and independent approach to data analytics. DataOps applies to the entire data lifecycle from data preparation to reporting, and recognizes the interconnected nature of the data analytics team and information technology operations.

Management System (Open Source) is a socio-technical system that leverages the cumulative knowledge of management practitioners and evidenced based research from the past 130 years. The system was developed by DoD components in partnership with industry experts and academic researchers and builds off of the US Department of Wars version 1.0 open source management system - Training Within Industry.