Related Research Articles

In physics and engineering, fluid dynamics is a subdiscipline of fluid mechanics that describes the flow of fluids—liquids and gases. It has several subdisciplines, including aerodynamics and hydrodynamics. Fluid dynamics has a wide range of applications, including calculating forces and moments on aircraft, determining the mass flow rate of petroleum through pipelines, predicting weather patterns, understanding nebulae in interstellar space and modelling fission weapon detonation.

A fluid flowing around an object exerts a force on it. Lift is the component of this force that is perpendicular to the oncoming flow direction. It contrasts with the drag force, which is the component of the force parallel to the flow direction. Lift conventionally acts in an upward direction in order to counter the force of gravity, but it can act in any direction at right angles to the flow.

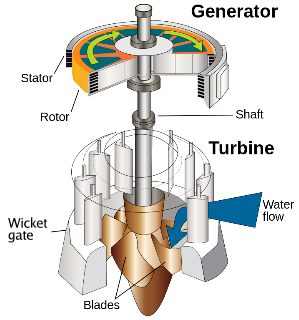

A water turbine is a rotary machine that converts kinetic energy and potential energy of water into mechanical work.

A viscometer is an instrument used to measure the viscosity of a fluid. For liquids with viscosities which vary with flow conditions, an instrument called a rheometer is used. Thus, a rheometer can be considered as a special type of viscometer. Viscometers only measure under one flow condition.

A carburetor or carburettor is a device that mixes air and fuel for internal combustion engines in an appropriate air–fuel ratio for combustion. The term is sometimes colloquially shortened to carb in the UK and North America or to carby in Australia.

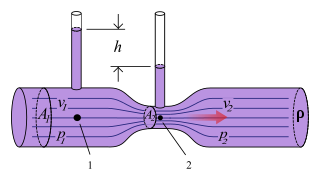

In fluid dynamics, Bernoulli's principle states that an increase in the speed of a fluid occurs simultaneously with a decrease in static pressure or a decrease in the fluid's potential energy. The principle is named after Daniel Bernoulli who published it in his book Hydrodynamica in 1738. Although Bernoulli deduced that pressure decreases when the flow speed increases, it was Leonhard Euler in 1752 who derived Bernoulli's equation in its usual form. The principle is only applicable for isentropic flows: when the effects of irreversible processes and non-adiabatic processes are small and can be neglected.

Flow measurement is the quantification of bulk fluid movement. Flow can be measured in a variety of ways. The common types of flowmeters with industrial applications are listed below:

A weir or low head dam is a barrier across the width of a river that alters the flow characteristics of water and usually results in a change in the height of the river level. Weirs are also used to control the flow of water for outlets of lakes, ponds, and reservoirs. There are many weir designs, but commonly water flows freely over the top of the weir crest before cascading down to a lower level.

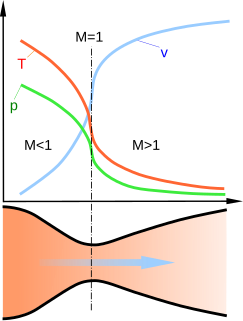

A de Laval nozzle is a tube which is pinched in the middle, making a carefully balanced, asymmetric hourglass shape. It is used to accelerate a compressible fluid to supersonic speeds in the axial (thrust) direction, by converting the thermal energy of the flow into kinetic energy. De Laval nozzles are widely used in some types of steam turbines and rocket engine nozzles. It also sees use in supersonic jet engines.

A siphon is any of a wide variety of devices that involve the flow of liquids through tubes. In a narrower sense, the word refers particularly to a tube in an inverted "U" shape, which causes a liquid to flow upward, above the surface of a reservoir, with no pump, but powered by the fall of the liquid as it flows down the tube under the pull of gravity, then discharging at a level lower than the surface of the reservoir from which it came.

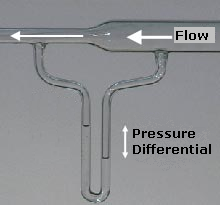

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section of a pipe. The Venturi effect is named after its discoverer, the 18th century Italian physicist, Giovanni Battista Venturi.

An injector is a system of ducting and nozzles used to direct the flow of a high-pressure fluid in such a way that a lower pressure fluid is entrained in the jet and carried through a duct to a region of higher pressure. It is a fluid-dynamic pump with no moving parts, excepting a valve to control inlet flow. A steam injector is a typical application of the principle used to deliver cold water to a boiler against its own pressure, using its own live or exhaust steam, replacing any mechanical pump. When first developed, its operation was intriguing because it seemed paradoxical, almost like perpetual motion, but it was later explained using thermodynamics. Other types of injector may use other pressurised motive fluids such as air.

An orifice plate is a device used for measuring flow rate, for reducing pressure or for restricting flow.

Choked flow is a compressible flow effect. The parameter that becomes "choked" or "limited" is the fluid velocity.

A blowout is the uncontrolled release of crude oil and/or natural gas from an oil well or gas well after pressure control systems have failed. Modern wells have blowout preventers intended to prevent such an occurrence. An accidental spark during a blowout can lead to a catastrophic oil or gas fire.

In fluid mechanics, pressure head is the height of a liquid column that corresponds to a particular pressure exerted by the liquid column on the base of its container. It may also be called static pressure head or simply static head.

Unconventional wind turbines are those that differ significantly from the most common types in use.

A spray nozzle is a precision device that facilitates dispersion of liquid into a spray. Nozzles are used for three purposes: to distribute a liquid over an area, to increase liquid surface area, and create impact force on a solid surface. A wide variety of spray nozzle applications use a number of spray characteristics to describe the spray.

A Tesla valve, called a valvular conduit by its inventor, is a fixed-geometry passive check valve. It allows a fluid to flow preferentially in one direction, without moving parts. The device is named after Nikola Tesla, who was awarded U.S. Patent 1,329,559 in 1920 for its invention. The patent application describes the invention as follows:

The interior of the conduit is provided with enlargements, recesses, projections, baffles, or buckets which, while offering virtually no resistance to the passage of the fluid in one direction, other than surface friction, constitute an almost impassable barrier to its flow in the opposite direction.

The Parshall flume is an open channel flow metering device that was developed to measure the flow of surface waters and irrigation flows. The Parshall flume is a fixed hydraulic structure. It is used to measure volumetric flow rate in industrial discharges, municipal sewer lines, and influent/effluent flows in wastewater treatment plants. The Parshall flume accelerates flow through a contraction of both the parallel sidewalls and a drop in the floor at the flume throat. Under free-flow conditions the depth of water at specified location upstream of the flume throat can be converted to a rate of flow. Some states specify the use of Parshall flumes, by law, for certain situations.

References

- ↑ de Sa, D.O. (2001). Instrumentation Fundamentals for Process Control. Taylor & Francis. p. 9. ISBN 9781560329015 . Retrieved 2015-04-21.

- ↑ Cone, V.M. (23 April 1917). "The Venturi Flume". Journal of Agricultural Research. 9 (4): 115. Retrieved 2 May 2022.

- ↑ Bennett, Ray S. (March 1972). Cutthroat Flume Discharge Relations (PDF) (Report). Agency for International Development. Retrieved 2 May 2022.

- ↑ "Venturi flume: Definition from Answers.com". answers.com. Retrieved 2015-04-21.

- ↑ "Archived copy". Archived from the original on 2008-12-12. Retrieved 2009-06-07.

{{cite web}}: CS1 maint: archived copy as title (link)