Related Research Articles

Laser printing is an electrostatic digital printing process. It produces high-quality text and graphics by repeatedly passing a laser beam back and forth over a negatively charged cylinder called a "drum" to define a differentially charged image. The drum then selectively collects electrically charged powdered ink (toner), and transfers the image to paper, which is then heated to permanently fuse the text, imagery, or both to the paper. As with digital photocopiers, laser printers employ a xerographic printing process. Laser printing differs from traditional xerography as implemented in analog photocopiers in that in the latter, the image is formed by reflecting light off an existing document onto the exposed drum.

The following list comprises significant milestones in the development of photography technology.

Duplicating machines were the predecessors of modern document-reproduction technology. They have now been replaced by digital duplicators, scanners, laser printers and photocopiers, but for many years they were the primary means of reproducing documents for limited-run distribution. The duplicator was pioneered by Thomas Edison and David Gestetner, with Gestetner dominating the market up until the late 1990s.

In photography, reversal film or slide film is a type of photographic film that produces a positive image on a transparent base. Instead of negatives and prints, reversal film is processed to produce transparencies or diapositives. Reversal film is produced in various sizes, from 35 mm to roll film to 8×10 inch sheet film.

Color photography is photography that uses media capable of capturing and reproducing colors. By contrast, black-and-white or gray-monochrome photography records only a single channel of luminance (brightness) and uses media capable only of showing shades of gray.

Xerography is a dry photocopying technique. Originally called electrophotography, it was renamed xerography—from the Greek roots ξηρόςxeros, meaning "dry" and -γραφία-graphia, meaning "writing"—to emphasize that unlike reproduction techniques then in use such as cyanotype, the process of xerography used no liquid chemicals.

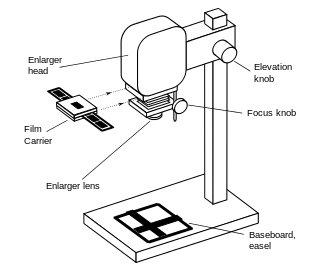

An enlarger is a specialized transparency projector used to produce photographic prints from film or glass negatives, or from transparencies.

Photographic printing is the process of producing a final image on paper for viewing, using chemically sensitized paper. The paper is exposed to a photographic negative, a positive transparency , or a digital image file projected using an enlarger or digital exposure unit such as a LightJet or Minilab printer. Alternatively, the negative or transparency may be placed atop the paper and directly exposed, creating a contact print. Digital photographs are commonly printed on plain paper, for example by a color printer, but this is not considered "photographic printing".

Photogravure is a process for printing photographs, also sometimes used for reproductive intaglio printmaking. It is a photo-mechanical process whereby a copper plate is grained and then coated with a light-sensitive gelatin tissue which had been exposed to a film positive, and then etched, resulting in a high quality intaglio plate that can reproduce detailed continuous tones of a photograph.

Instant film is a type of photographic film that was introduced by Polaroid Corporation to produce a visible image within minutes or seconds of the photograph's exposure. The film contains the chemicals needed for developing and fixing the photograph, and the camera exposes and initiates the developing process after a photo has been taken.

In infrared photography, the photographic film or image sensor used is sensitive to infrared light. The part of the spectrum used is referred to as near-infrared to distinguish it from far-infrared, which is the domain of thermal imaging. Wavelengths used for photography range from about 700 nm to about 900 nm. Film is usually sensitive to visible light too, so an infrared-passing filter is used; this lets infrared (IR) light pass through to the camera, but blocks all or most of the visible light spectrum; these filters thus look black (opaque) or deep red.

A minilab is a small photographic developing and printing system or machine, as opposed to large centralized photo developing labs. Many retail stores use film or digital minilabs to provide on-site photo finishing services.

Gum printing is a way of making photographic reproductions without the use of silver halides. The process uses salts of dichromate in common with a number of other related processes such as sun printing.

The Photostat machine, or Photostat, was an early projection photocopier created in the decade of the 1900s by the Commercial Camera Company, which became the Photostat Corporation. The "Photostat" name, which was originally a trademark of the company, became genericized, and was often used to refer to similar machines produced by the RetinalGraph Company or to any copy made by any such machine.

Thermal paper is a special fine paper that is coated with a material formulated to change color locally when exposed to heat. It is used in thermal printers, particularly in inexpensive devices such as adding machines, cash registers, and credit card terminals and small, lightweight portable printers.

Dye transfer is a continuous-tone color photographic printing process. It was used to print Technicolor films, as well as to produce paper colour prints used in advertising, or large transparencies for display.

A photocopier is a machine that makes copies of documents and other visual images onto paper or plastic film quickly and cheaply. Most modern photocopiers use a technology called xerography, a dry process that uses electrostatic charges on a light-sensitive photoreceptor to first attract and then transfer toner particles onto paper in the form of an image. The toner is then fused onto the paper using heat, pressure, or a combination of both. Copiers can also use other technologies, such as inkjet, but xerography is standard for office copying.

Photographic film is a strip or sheet of transparent film base coated on one side with a gelatin emulsion containing microscopically small light-sensitive silver halide crystals. The sizes and other characteristics of the crystals determine the sensitivity, contrast, and resolution of the film. Film is typically segmented in frames, that give rise to separate photographs.

A heliographic copier or heliographic duplicator is an apparatus used in the world of reprography for making contact prints on paper from original drawings made with that purpose on tracing paper, parchment paper or any other transparent or translucent material using different procedures. In general terms some type of heliographic copier is used for making: Hectographic prints, Ferrogallic prints, Gel-lithographs or Silver halide prints. All of them, until a certain size, can be achieved using a contact printer with an appropriate lamp but for big engineering and architectural plans, the heliographic copiers used with the cyanotype and the diazotype technologies, are of the roller type, which makes them completely different from contact printers.

A contact copier is a device used to copy an image by illuminating a film negative with the image in direct contact with a photosensitive surface. The more common processes are negative, where clear areas in the original produce an opaque or hardened photosensitive surface, but positive processes are available. The light source is usually an actinic bulb internal or external to the device

References

- ↑ Michael R. Peres (20 June 2014). The Focal Encyclopedia ofPhotography. Routledge. pp. 11 –. ISBN 978-1-136-10614-9.

- 1 2 cool.conservation us.org

- 1 2 Bonnier Corporation (January 1965). "Popular Science". The Popular Science Monthly. Bonnier Corporation: 128–. ISSN 0161-7370.

kodak verifax.

- ↑ Lillian Hoddeson (11 November 2002). True Genius: The Life and Science of JohnBardeen. Joseph Henry Press. pp. 242 –. ISBN 978-0-309-50064-7.