A boat is a watercraft of a large range of types and sizes, but generally smaller than a ship, which is distinguished by its larger size, shape, cargo or passenger capacity, or its ability to carry boats.

The bilge of a ship or boat is the part of the hull that would rest on the ground if the vessel were unsupported by water. The "turn of the bilge" is the transition from the bottom of a hull to the sides of a hull.

Shipbuilding is the construction of ships and other floating vessels. It normally takes place in a specialized facility known as a shipyard. Shipbuilders, also called shipwrights, follow a specialized occupation that traces its roots to before recorded history.

The gunwale is the top edge of the hull of a ship or boat.

A cog is a type of ship that first appeared in the 10th century, and was widely used from around the 12th century on. Cogs were clinker-built, generally of oak. These vessels were fitted with a single mast and a square-rigged single sail. They were mostly associated with seagoing trade in north-west medieval Europe, especially the Hanseatic League. Typical seagoing cogs ranged from about 15 to 25 meters in length, with a beam of 5 to 8 meters and were 30–200 tons burthen. Cogs were rarely as large as 300 tons although a few were considerably larger, over 1,000 tons.

Boat building is the design and construction of boats and their systems. This includes at a minimum a hull, with propulsion, mechanical, navigation, safety and other systems as a craft requires.

A wheelwright is a craftsman who builds or repairs wooden wheels. The word is the combination of "wheel" and the word "wright", as in shipwright and arkwright. This occupational name became the English surname Wright. It also appears in surnames like Cartwright and Wainwright. It corresponds with skilful metal workers being called Smith.

This is a glossary of nautical terms; an alphabetical listing of terms and expressions connected with ships, shipping, seamanship and navigation on water, but not necessarily on the sea. Some remain current, while many date from the 17th to 19th centuries. The word nautical derives from the Latin nauticus, from Greek nautikos, from nautēs: sailor, from naus: ship.

A sewn boat is a type of wooden boat which is clinker built with its planks sewn, stitched, tied, or bound together with tendons or flexible wood, such as roots and willow branches. Sewn boat construction techniques were used in many parts of the world prior to the development of metal fasteners, and continued to be used long after that time for small boats to reduce construction costs where metal fasteners were too expensive.

A ship's wheel or boat's wheel is a device used aboard a water vessel to steer that vessel and control its course. Together with the rest of the steering mechanism, it forms part of the helm. It is connected to a mechanical, electric servo, or hydraulic system which alters the horizontal angle of the vessel's rudder relative to its hull. In some modern ships the wheel is replaced with a simple toggle that remotely controls an electro-mechanical or electro-hydraulic drive for the rudder, with a rudder position indicator presenting feedback to the helmsman.

Clinker built is a method of boat building where the edges of hull planks overlap each other. Where necessary in larger craft, shorter planks can be joined end to end, creating a longer strake or hull plank. The technique originated in Scandinavia, and was successfully used by the Anglo-Saxons, Frisians, Scandinavians, typically in the vessels known as cogs employed by the Hanseatic League. Carvel construction, where plank edges are butted smoothly, seam to seam, supplanted clinker construction in large vessels as the demand for capacity surpassed the limits of clinker construction..

On a vessel's hull, a strake is a longitudinal course of planking or plating which runs from the boat's stempost to the sternpost or transom. The garboard strakes are the two immediately adjacent to the keel on each side.

The Hjortspring boat is a vessel designed as a large canoe, from the Scandinavian Pre-Roman Iron Age. It was built circa 400–300 BC. The hull and remains were rediscovered and excavated in 1921–1922 from the bog of Hjortspring Mose on the island of Als in Sønderjylland, southern Denmark. The boat is the oldest find of a wooden plank ship in Scandinavia and it closely resembles the thousands of petroglyph images of Nordic Bronze Age ships found throughout Scandinavia. The vessel is a clinker-built wooden boat of more than 19 metres length overall, 13.6 metres long inside, and 2 metres wide. Ten thwarts that could have served as seats, span the boat with room for two persons each; this suggests space for a crew of at least 20 who propelled the boat with paddles. The boat would have weighed an estimated 530 kilograms (1,168 lb), making it easily portable by its crew.

A tieback is a structural element installed in soil or rock to transfer applied tensile load into the ground. Typically in the form of a horizontal wire or rod, or a helical anchor, a tieback is commonly used along with other retaining systems to provide additional stability to cantilevered retaining walls. With one end of the tieback secured to the wall, the other end is anchored to a stable structure, such as a concrete deadman which has been driven into the ground or anchored into earth with sufficient resistance. The tieback-deadman structure resists forces that would otherwise cause the wall to lean, as for example, when a seawall is pushed seaward by water trapped on the landward side after a heavy rain.

Shell plating is the outer-most structure on the hull of a steel or aluminum ship or boat.

A thwart is a part of an undecked boat that provides seats for the crew and structural rigidity for the hull. A thwart goes from one side of the hull to the other. There might be just one thwart in a small boat, or many in a larger boat, especially if several oarsmen need to be accommodated.

In ships, frames are ribs that are transverse bolted or welded to the keel. Frames support the hull and give the ship its shape and strength.

Lashed-lug boats are ancient boat-building techniques of the Austronesian peoples. It is characterized by the use of sewn holes and later dowels ("treenails") to stitch planks edge-to-edge onto a dugout keel and solid carved wood pieces that form the caps for the prow and stern. The planks are further lashed together and to ribs with fiber ropes wrapped around protruding carved lugs on the inside surfaces. Unlike carvel construction, the shell of the boat is created first, prior to being fastened to the ribs. The seams between planks are also sealed with absorbent tapa bark and fiber that expands when wet or caulked with resin-based preparations.</ref>

This is a glossary of nautical terms; an alphabetical listing of terms and expressions connected with ships, shipping, seamanship and navigation on water, but not necessarily on the sea. Some remain current, while many date from the 17th to 19th centuries. The word nautical derives from the Latin nauticus, from Greek nautikos, from nautēs: sailor, from naus: ship.

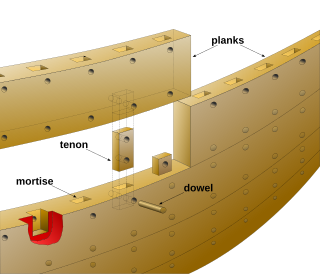

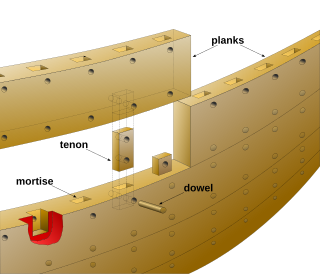

Phoenician joints is a locked mortise and tenon wood joinery technique used in shipbuilding to fasten watercraft hulls. The locked mortise and tenon technique consists of cutting a mortise, or socket, into the edges of two planks and fastening them together with a rectangular wooden knob. The assembly is then locked in place by driving a dowel through one or more holes drilled through the mortise side wall and tenon.