A soldering iron is a hand tool used in soldering. It supplies heat to melt solder so that it can flow into the joint between two workpieces.

A calorimeter is an object used for calorimetry, or the process of measuring the heat of chemical reactions or physical changes as well as heat capacity. Differential scanning calorimeters, isothermal micro calorimeters, titration calorimeters and accelerated rate calorimeters are among the most common types. A simple calorimeter just consists of a thermometer attached to a metal container full of water suspended above a combustion chamber. It is one of the measurement devices used in the study of thermodynamics, chemistry, and biochemistry.

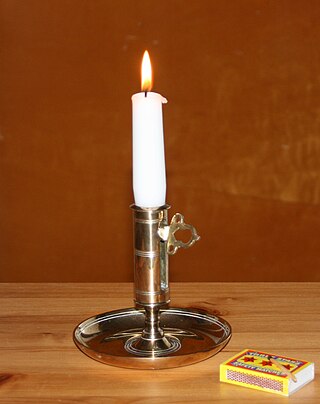

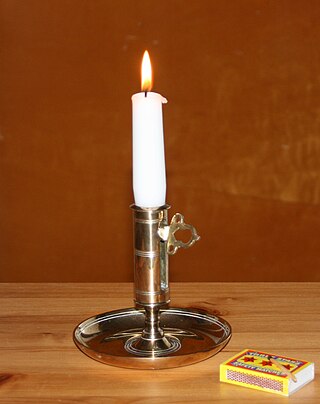

A candle is an ignitable wick embedded in wax, or another flammable solid substance such as tallow, that provides light, and in some cases, a fragrance. A candle can also provide heat or a method of keeping time.

A microwave oven is an electric oven that heats and cooks food by exposing it to electromagnetic radiation in the microwave frequency range. This induces polar molecules in the food to rotate and produce thermal energy in a process known as dielectric heating. Microwave ovens heat foods quickly and efficiently because excitation is fairly uniform in the outer 25–38 mm(1–1.5 inches) of a homogeneous, high-water-content food item.

Surface-mount technology (SMT), originally called planar mounting, is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). An electrical component mounted in this manner is referred to as a surface-mount device (SMD). In industry, this approach has largely replaced the through-hole technology construction method of fitting components, in large part because SMT allows for increased manufacturing automation which reduces cost and improves quality. It also allows for more components to fit on a given area of substrate. Both technologies can be used on the same board, with the through-hole technology often used for components not suitable for surface mounting such as large transformers and heat-sinked power semiconductors.

Brazing is a metal-joining process in which two or more metal items are joined together by melting and flowing a filler metal into the joint, with the filler metal having a lower melting point than the adjoining metal.

Rosin, also called colophony or Greek pitch, is a solid form of resin obtained from pines and some other plants, mostly conifers, produced by heating fresh liquid resin to vaporize the volatile liquid terpene components. It is semi-transparent and varies in color from yellow to black. At room temperature rosin is brittle, but it melts at stove-top temperature. It chiefly consists of various resin acids, especially abietic acid. The term colophony comes from colophonia resina, Latin for "resin from Colophon", an ancient Ionic city.

Induction heating is the process of heating electrically conductive materials, namely metals or semi-conductors, by electromagnetic induction, through heat transfer passing through an induction coil that creates an electromagnetic field within the coil to heat up and possibly melt steel, copper, brass, graphite, gold, silver, aluminum, or carbide. An induction heater consists of an electromagnet and an electronic oscillator that passes a high-frequency alternating current (AC) through the electromagnet. The rapidly alternating magnetic field penetrates the object, generating electric currents inside the conductor called eddy currents. The eddy currents flow through the resistance of the material, and heat it by Joule heating. In ferromagnetic and ferrimagnetic materials, such as iron, heat also is generated by magnetic hysteresis losses. The frequency of the electric current used for induction heating depends on the object size, material type, coupling, and the penetration depth.

Wax play is a form of temperature play practiced in a BDSM context, in which wax from a candle is dripped onto a person's naked skin, in order to introduce a slight burning sensation to the skin.

Wood's metal, also known as Lipowitz's alloy or by the commercial names Cerrobend, Bendalloy, Pewtalloy and MCP 158, is a metal alloy that is useful for soldering and making custom metal parts, but which is toxic to touch or breathe vapors from. The alloy is named for Barnabas Wood, who first created and patented the alloy in 1860. It is a eutectic, fusible alloy of 50% bismuth, 26.7% lead, 13.3% tin, and 10% cadmium by mass. It has a melting point of approximately 70 °C (158 °F).

A heat gun is a device used to emit a stream of hot air, usually at temperatures between 100 °C and 550 °C (200-1000 °F), with some hotter models running around 760 °C (1400 °F), which can be held by hand. Heat guns usually have the form of an elongated body pointing at what is to be heated, with a handle fixed to it at right angles and a pistol grip trigger in the same pistol form factor as many other power tools.

Microcrystalline waxes are a type of wax produced by de-oiling petrolatum, as part of the petroleum refining process. In contrast to the more familiar paraffin wax which contains mostly unbranched alkanes, microcrystalline wax contains a higher percentage of isoparaffinic (branched) hydrocarbons and naphthenic hydrocarbons. It is characterized by the fineness of its crystals in contrast to the larger crystal of paraffin wax. It consists of high molecular weight saturated aliphatic hydrocarbons. It is generally darker, more viscous, denser, tackier and more elastic than paraffin waxes, and has a higher molecular weight and melting point. The elastic and adhesive characteristics of microcrystalline waxes are related to the non-straight chain components which they contain. Typical microcrystalline wax crystal structure is small and thin, making them more flexible than paraffin wax. It is commonly used in cosmetic formulations.

An induction furnace is an electrical furnace in which the heat is applied by induction heating of metal. Induction furnace capacities range from less than one kilogram to one hundred tons, and are used to melt iron and steel, copper, aluminum, and precious metals.

Ultrasonic cleaning is a process that uses ultrasound to agitate a fluid, with a cleaning effect. Ultrasonic cleaners come in a variety of sizes, from small desktop units with an internal volume of less than 0.5 litres (0.13 US gal), to large industrial units with volumes approaching 1,000 litres.

Hot-melt adhesive (HMA), also known as hot glue, is a form of thermoplastic adhesive that is commonly sold as solid cylindrical sticks of various diameters designed to be applied using a hot glue gun. The gun uses a continuous-duty heating element to melt the plastic glue, which the user pushes through the gun either with a mechanical trigger mechanism on the gun, or with direct finger pressure. The glue squeezed out of the heated nozzle is initially hot enough to burn and even blister skin. The glue is sticky when hot, and solidifies in a few seconds to one minute. Hot-melt adhesives can also be applied by dipping or spraying, and are popular with hobbyists and crafters both for affixing and as an inexpensive alternative to resin casting.

A candle warmer is an electric warmer that melts a candle or scented wax to release its scent. The candle warmer shown is intended to be used with jar candles or candles in cups, not with taper candles or candles without containers large enough to accommodate all the melted wax. Some candle warmers have a built-in bowl in which the candle is placed.

Soy candles are candles made from soy wax, which is a processed form of soybean oil. They are usually container candles, because soy wax typically has a lower melting point than traditional waxes, but can also be made into pillar candles if certain additives are mixed into the soy wax.

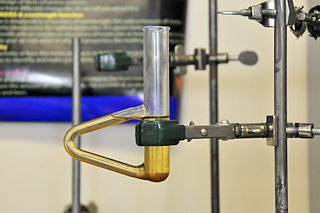

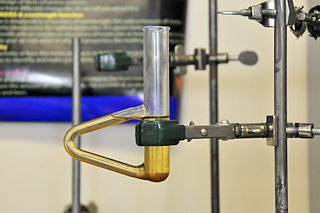

The Thiele tube, named after the German chemist Johannes Thiele, is a laboratory glassware designed to contain and heat an oil bath. Such a setup is commonly used in the determination of the melting point of a substance. The apparatus resembles a glass test tube with an attached handle.

A melting tank is a tank used by manufacturing companies to manufacture a variety of products.

Soldering is a process in which two or more items are joined by melting and putting a filler metal (solder) into the joint, the filler metal having a lower melting point than the adjoining metal. Unlike welding, soldering does not involve melting the work pieces. In brazing, the work piece metal also does not melt, but the filler metal is one that melts at a higher temperature than in soldering. In the past, nearly all solders contained lead, but environmental and health concerns have increasingly dictated use of lead-free alloys for electronics and plumbing purposes.