Brass is an alloy of copper and zinc, in proportions which can be varied to achieve varying mechanical and electrical properties. It is a substitutional alloy: atoms of the two constituents may replace each other within the same crystal structure. In contrast, bronze is an alloy of copper and tin.

Magnetostriction is a property of ferromagnetic materials that causes them to change their shape or dimensions during the process of magnetization. The variation of materials' magnetization due to the applied magnetic field changes the magnetostrictive strain until reaching its saturation value, λ. The effect was first identified in 1842 by James Joule when observing a sample of iron.

Thermal analysis is a branch of materials science where the properties of materials are studied as they change with temperature. Several methods are commonly used – these are distinguished from one another by the property which is measured:

In materials science, superplasticity is a state in which solid crystalline material is deformed well beyond its usual breaking point, usually over about 200% during tensile deformation. Such a state is usually achieved at high homologous temperature. Examples of superplastic materials are some fine-grained metals and ceramics. Other non-crystalline materials (amorphous) such as silica glass and polymers also deform similarly, but are not called superplastic, because they are not crystalline; rather, their deformation is often described as Newtonian fluid. Superplastically deformed material gets thinner in a very uniform manner, rather than forming a "neck" that leads to fracture. Also, the formation of microvoids, which is another cause of early fracture, is inhibited.

An amorphous metal is a solid metallic material, usually an alloy, with disordered atomic-scale structure. Most metals are crystalline in their solid state, which means they have a highly ordered arrangement of atoms. Amorphous metals are non-crystalline, and have a glass-like structure. But unlike common glasses, such as window glass, which are typically electrical insulators, amorphous metals have good electrical conductivity. There are several ways in which amorphous metals can be produced, including extremely rapid cooling, physical vapor deposition, solid-state reaction, ion irradiation, and mechanical alloying.

A shape-memory alloy is an alloy that "remembers" its original shape and that when deformed returns to its pre-deformed shape when heated. This material is a lightweight, solid-state alternative to conventional actuators such as hydraulic, pneumatic, and motor-based systems. Shape-memory alloys have applications in robotics and automotive, aerospace and biomedical industries.

Titanium alloys are metals that contain a mixture of titanium and other chemical elements. Such alloys have very high tensile strength and toughness. They are light in weight, have extraordinary corrosion resistance and the ability to withstand extreme temperatures. However, the high cost of both raw materials and processing limit their use to military applications, aircraft, spacecraft, bicycles, medical devices, jewelry, highly stressed components such as connecting rods on expensive sports cars and some premium sports equipment and consumer electronics.

A superalloy, or high-performance alloy, is an alloy that exhibits several key characteristics: excellent mechanical strength, resistance to thermal creep deformation, good surface stability, and resistance to corrosion or oxidation. The crystal structure is typically face-centered cubic austenitic. Examples of such alloys are Hastelloy, Inconel, Waspaloy, Rene alloys, Incoloy, MP98T, TMS alloys, and CMSX single crystal alloys.

Microstructure is the very small scale structure of a material, defined as the structure of a prepared surface of material as revealed by a microscope above 25× magnification. The microstructure of a material can strongly influence physical properties such as strength, toughness, ductility, hardness, corrosion resistance, high/low temperature behaviour or wear resistance. These properties in turn govern the application of these materials in industrial practice. Microstructure at scales smaller than can be viewed with optical microscopes is often called nanostructure, while the structure in which individual atoms are arranged is known as crystal structure. The nanostructure of biological specimens is referred to as ultrastructure. A microstructure’s influence on the mechanical and physical properties of a material is primarily governed by the different defects present or absent of the structure. These defects can take many forms but the primary ones are the pores. Even if those pores play a very important role in the definition of the characteristics of a material, so does its composition. In fact, for many materials, different phases can exist at the same time. These phases have different properties and if managed correctly, can prevent the fracture of the material.

Mullite or porcelainite is a rare silicate mineral of post-clay genesis. It can form two stoichiometric forms: 3Al2O32SiO2 or 2Al2O3 SiO2. Unusually, mullite has no charge balancing cations present. As a result, there are three different aluminium sites: two distorted tetrahedral and one octahedral.

Superplastic forming (SPF) is an industrial process used for creating precise and complex components out of certain types of materials called superplastic materials.

Pure gold is slightly reddish yellow in color, but colored gold in various other colors can be produced.

Friction stir processing (FSP) is a method of changing the properties of a metal through intense, localized plastic deformation. This deformation is produced by forcibly inserting a non-consumable tool into the workpiece, and revolving the tool in a stirring motion as it is pushed laterally through the workpiece. The precursor of this technique, friction stir welding, is used to join multiple pieces of metal without creating the heat affected zone typical of fusion welding.

Eutectic bonding, also referred to as eutectic soldering, describes a wafer bonding technique with an intermediate metal layer that can produce a eutectic system. Those eutectic metals are alloys that transform directly from solid to liquid state, or vice versa from liquid to solid state, at a specific composition and temperature without passing a two-phase equilibrium, i.e. liquid and solid state. The fact that the eutectic temperature can be much lower than the melting temperature of the two or more pure elements can be important in eutectic bonding.

Twinning-Induced Plasticity steel which is also known as TWIP steel is a class of austenitic steels which can deform by both glide of individual dislocations and mechanical twinning on the {1 1 1}γ<1 1 >γ system. They have outstanding mechanical properties at room temperature combining high strength and ductility based on a high work-hardening capacity. TWIP steels have mostly high content in Mn and small additions of elements such C, Si, or Al. The steels have low stacking fault energy at room temperature. Although the details of the mechanisms controlling strain-hardening in TWIP steels are still unclear, the high strain-hardening is commonly attributed to the reduction of the dislocation mean free path with the increasing fraction of deformation twins as these are considered to be strong obstacles to dislocation glide. Therefore, a quantitative study of deformation twinning in TWIP steels is critical to understand their strain-hardening mechanisms and mechanical properties. Deformation twinning can be considered as a nucleation and growth process. Twin growth is assumed to proceed by co-operative movement of Shockley partials on subsequent {111} planes.

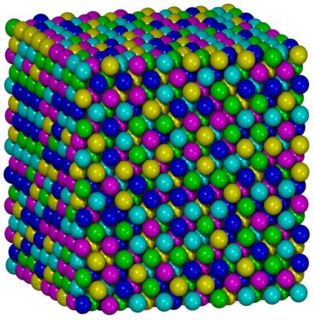

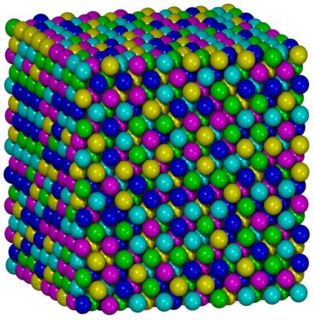

High-entropy alloys (HEAs) are alloys that are formed by mixing equal or relatively large proportions of (usually) five or more elements. Prior to the synthesis of these substances, typical metal alloys comprised one or two major components with smaller amounts of other elements. For example, additional elements can be added to iron to improve its properties, thereby creating an iron based alloy, but typically in fairly low proportions, such as the proportions of carbon, manganese, and the like in various steels. Hence, high entropy alloys are a novel material. The term “high-entropy alloys” was coined because the entropy increase of mixing is substantially higher when there is a larger number of elements in the mix, and their proportions are more nearly equal.

Ti-6Al-7Nb is an alpha-beta titanium alloy first synthesized in 1977. It features high strength and has similar properties as the cytotoxic vanadium containing alloy Ti-6Al-4V. Ti-6Al-7Nb is used as a material for hip protheses. Ti―6Al―7Nb is one of the titanium alloys that built of hexagonal α phase and regular body-centred phase β. The alloy is characterized by added advantageous mechanical properties, it has higher corrosion resistance and biotolerance in relation to Ti-6Al-V alloys.

Atul Harish Chokshi is an Indian materials scientist, metallurgical engineer and a professor at the Department of Materials Engineering of the Indian Institute of Science. He is known for his studies on high temperature deformation and failure of ceramic materials and is an elected fellow of all the three major Indian science academies viz. the National Academy of Sciences, India, Indian Academy of Sciences, and Indian National Science Academy as well as the Indian National Academy of Engineering. The Council of Scientific and Industrial Research, the apex agency of the Government of India for scientific research, awarded him the Shanti Swarup Bhatnagar Prize for Science and Technology, one of the highest Indian science awards for his contributions to Engineering Sciences in 2003.

Dissimilar friction stir welding (DFSW) is the application of friction stir welding (FSW), invented in The Welding Institute (TWI) in 1991, to join different base metals including aluminum, copper, steel, titanium, magnesium and other materials. It is based on solid state welding that means there is no melting. DFSW is based on a frictional heat generated by a simple tool in order to soften the materials and stir them together using both tool rotational and tool traverse movements. In the beginning, it is mainly used for joining of aluminum base metals due to existence of solidification defects in joining them by fusion welding methods such as porosity along with thick Intermetallic compounds. DFSW is taken into account as an efficient method to join dissimilar materials in the last decade. There are many advantages for DFSW in compare with other welding methods including low-cost, user-friendly, and easy operation procedure resulting in enormous usages of friction stir welding for dissimilar joints. Welding tool, base materials, backing plate (fixture), and a milling machine are required materials and equipment for DFSW. On the other hand, other welding methods, such as Shielded Metal Arc Welding (SMAW) typically need highly professional operator as well as quite expensive equipment.