SMP may refer to:

An actuator is a component of a machine that is responsible for moving and controlling a mechanism or system, for example by opening a valve. In simple terms, it is a "mover".

In metallurgy, a shape-memory alloy (SMA) is an alloy that can be deformed when cold but returns to its pre-deformed ("remembered") shape when heated. It is also known in other names such as memory metal, memory alloy, smart metal, smart alloy, and muscle wire. The "memorized geometry" can be modified by fixating the desired geometry and subjecting it to a thermal treatment, for example a wire can be taught to memorize the shape of a coil spring.

Smart materials, also called intelligent or responsive materials, are designed materials that have one or more properties that can be significantly changed in a controlled fashion by external stimuli, such as stress, moisture, electric or magnetic fields, light, temperature, pH, or chemical compounds. Smart materials are the basis of many applications, including sensors and actuators, or artificial muscles, particularly as electroactive polymers (EAPs).

ADSM may refer to

Polyester is a category of polymers that contain the ester functional group in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include naturally occurring chemicals, such as in plants and insects, as well as synthetics such as polybutyrate. Natural polyesters and a few synthetic ones are biodegradable, but most synthetic polyesters are not. Synthetic polyesters are used extensively in clothing.

Food packaging is a packaging system specifically designed for food and represents one of the most important aspects among the processes involved in the food industry, as it provides protection from chemical, biological and physical alterations. The main goal of food packaging is to provide a practical means of protecting and delivering food goods at a reasonable cost while meeting the needs and expectations of both consumers and industries. Additionally, current trends like sustainability, environmental impact reduction, and shelf-life extension have gradually become among the most important aspects in designing a packaging system.

Nickel titanium, also known as nitinol, is a metal alloy of nickel and titanium, where the two elements are present in roughly equal atomic percentages. Different alloys are named according to the weight percentage of nickel; e.g., nitinol 55 and nitinol 60.

Shape-memory polymers (SMPs) are polymeric smart materials that have the ability to return from a deformed state to their original (permanent) shape when induced by an external stimulus (trigger), such as temperature change.

The End of Life Vehicles Directive is a Directive of the European Union addressing the end of life for automotive products. Every year, motor vehicles which have reached the end of their useful lives create between 8 and 9 million tonnes of waste in the European Union. In 1997, the European Commission adopted a Proposal for a Directive to tackle this problem.

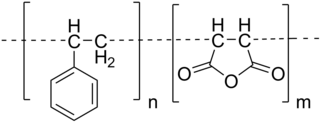

Styrene maleic anhydride is a synthetic polymer that is built-up of styrene and maleic anhydride monomers. The monomers can be almost perfectly alternating, making it an alternating copolymer, but (random) copolymerisation with less than 50% maleic anhydride content is also possible. The polymer is formed by a radical polymerization, using an organic peroxide as the initiator. The main characteristics of SMA copolymer are its transparent appearance, high heat resistance, high dimensional stability, and the specific reactivity of the anhydride groups. The latter feature results in the solubility of SMA in alkaline (water-based) solutions and dispersion.

In home automation systems and robotics, a flower robot is a simple electromechanical device with the appearance of a common flower, with components such as stem and leaves. First developed by Berufsbildende Schule 1 Kaiserslautern in 2006 and later by Carnegie Mellon University in 2007, flower robots are used as intelligent home appliances, with capabilities such as sensing, simple actuation for movements, and effectors such as lights or humidifier.

The terms active packaging, intelligent packaging, and smart packaging refer to amplified packaging systems used with foods, pharmaceuticals, and several other types of products. They help extend shelf life, monitor freshness, display information on quality, improve safety, and improve convenience.

Smart polymers, stimuli-responsive polymers or functional polymers are high-performance polymers that change according to the environment they are in. Such materials can be sensitive to a number of factors, such as temperature, humidity, pH, chemical compounds, the wavelength or intensity of light or an electrical or magnetic field and can respond in various ways, like altering color or transparency, becoming conductive or permeable to water or changing shape. Usually, slight changes in the environment are sufficient to induce large changes in the polymer's properties.

Artificial muscles, also known as muscle-like actuators, are materials or devices that mimic natural muscle and can change their stiffness, reversibly contract, expand, or rotate within one component due to an external stimulus. The three basic actuation responses– contraction, expansion, and rotation can be combined within a single component to produce other types of motions. Conventional motors and pneumatic linear or rotary actuators do not qualify as artificial muscles, because there is more than one component involved in the actuation.

SAES Getters S.p.A. is an Italian joint stock company, established in 1940. It is the parent company of the SAES industrial group, which focusses its business on the production of components and systems in advanced materials patented by the same company and used in various industrial and medical applications.

Soft robotics is a subfield of robotics that concerns the design, control, and fabrication of robots composed of compliant materials, instead of rigid links. In contrast to rigid-bodied robots built from metals, ceramics and hard plastics, the compliance of soft robots can improve their safety when working in close contact with humans.

4-dimensional printing uses the same techniques of 3D printing through computer-programmed deposition of material in successive layers to create a three-dimensional object. However, in 4D printing, the resulting 3D shape is able to morph into different forms in response to environmental stimulus, with the 4th dimension being the time-dependent shape change after the printing. It is therefore a type of programmable matter, wherein after the fabrication process, the printed product reacts with parameters within the environment and changes its form accordingly.

The thermally induced unidirectional shape-shape-memory effect is an effect classified within the new so-called smart materials. Polymers with thermally induced shape-memory effect are new materials, whose applications are recently being studied in different fields of science, communications and entertainment.

Covalent adaptable networks (CANs) are a type of polymer material that closely resemble thermosetting polymers (thermosets). However, they are distinguished from thermosets by the incorporation of dynamic covalent chemistry into the polymer network. When a stimulus (for example heat, light, pH, ...) is applied to the material, these dynamic bonds become active and can be broken or exchanged with other pending functional groups, allowing the polymer network to change its topology. This introduces reshaping, (re)processing and recycling into thermoset-like materials.