A cleanroom or clean room is an engineered space, which maintains a very low concentration of airborne particulates. It is well isolated, well-controlled from contamination, and actively cleansed. Such rooms are commonly needed for scientific research, and in industrial production for all nanoscale processes, such as semiconductor manufacturing. A cleanroom is designed to keep everything from dust, to airborne organisms, or vaporised particles, away from it, and so from whatever material is being handled inside it.

Radioactive contamination, also called radiological pollution, is the deposition of, or presence of radioactive substances on surfaces or within solids, liquids, or gases, where their presence is unintended or undesirable.

HEPA filter, also known as high-efficiency particulate absorbing filter and high-efficiency particulate arrestance filter, is an efficiency standard of air filters.

A pneumatic filter is a device which removes contaminants from a compressed air stream. This can be done using a number of different techniques and tools, such as a membrane that only allows air to pass through, or a "media" type that traps particulates but allows air to pass through to a Venturi tube.

An air purifier or air cleaner is a device which removes contaminants from the air in a room to improve indoor air quality. These devices are commonly marketed as being beneficial to allergy sufferers and asthmatics, and at reducing or eliminating second-hand tobacco smoke.

A particulate air filter is a device composed of fibrous, or porous materials which removes solid particulates such as dust, pollen, mold, and bacteria from the air. Filters containing an adsorbent or catalyst such as charcoal (carbon) may also remove odors and gaseous pollutants such as volatile organic compounds or ozone. Air filters are used in applications where air quality is important, notably in building ventilation systems and in engines.

Ultra-low particulate air (ULPA) is a type of filter. A ULPA filter can remove from the air at least 99.999% of dust, pollen, mold, bacteria and any airborne particles with a minimum particle penetration size of 120 nanometres. A ULPA filter can remove—to a large extent but not 100%—oil smoke, tobacco smoke, rosin smoke, smog, and insecticide dust. It can also remove carbon black to some extent. Some fan filter units incorporate ULPA filters. The EN 1822 and ISO 29463 standards may be used to rate ULPA filters.

A dust collector is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas. Designed to handle high-volume dust loads, a dust collector system consists of a blower, dust filter, a filter-cleaning system, and a dust receptacle or dust removal system. It is distinguished from air purifiers, which use disposable filters to remove dust.

A particle counter is used for monitoring and diagnosing particle contamination within specific clean media, including air, water and chemicals. Particle counters are used in a variety of applications in support of clean manufacturing practices, industries include: electronic components and assemblies, pharmaceutical drug products and medical devices, and industrial technologies such as oil and gas.

Swimming pool sanitation is the process of ensuring healthy conditions in swimming pools. Proper sanitation is needed to maintain the visual clarity of water and to prevent the transmission of infectious waterborne diseases.

The Institute of Environmental Sciences and Technology (IEST) is a non-profit, technical society where professionals who impact controlled environments connect, gain knowledge, receive advice, and work together to create industry best practices. The organization uniquely serves environmental test engineers, qualification engineers, cleanroom professionals, those who work in product testing and evaluation, and others who work across a variety of industries, including: acoustics, aerospace, automotive, biotechnology/bioscience, climatics, cleanroom operations/design/equipment/certification, dynamics, filtration, food processing, HVAC design, medical devices, nanotechnology, pharmaceutical, semiconductors/microelectronics, and shock/vibration. Information on ISO 14644 and ISO 14698 standards can be found through this organization.

Contamination control is the generic term for all activities aiming to control the existence, growth and proliferation of contamination in certain areas. Contamination control may refer to the atmosphere as well as to surfaces, to particulate matter as well as to microbes and to contamination prevention as well as to decontamination.

A biosafety cabinet (BSC)—also called a biological safety cabinet or microbiological safety cabinet—is an enclosed, ventilated laboratory workspace for safely working with materials contaminated with pathogens requiring a defined biosafety level. Several different types of BSC exist, differentiated by the degree of biocontainment they provide. BSCs first became commercially available in 1950.

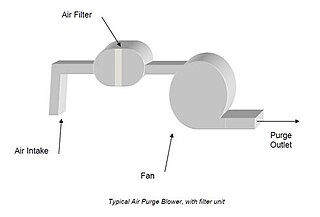

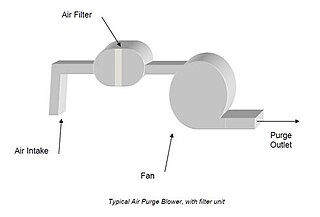

An air purge system is used to flush electrical control equipment with clean air before it is turned on. This ensures that the functionality of the equipment is not affected or damaged by the contaminants from the surrounding environment.

The clean air delivery rate (CADR) is a figure of merit that is the cubic feet per minute (CFM) of air that has had all the particles of a given size distribution removed. For air filters that have air flowing through them, it is the fraction of particles that have been removed from the air, multiplied by the air flow rate through the device. More precisely, it is the CFM of air in a 1,008-cubic-foot (28.5 m3) room that has had all the particles of a given size distribution removed from the air, over and above the rate at which the particles are naturally falling out of the air. Different filters have different abilities to remove different particle distributions, so three CADR's for a given device are typically measured: smoke, pollen, and dust. By combining the amount of airflow and particle removal efficiency, consumers are less likely to be misled by a high efficiency filter that is filtering a small amount of air, or by a high volume of air that is not being filtered very well.

A fan filter unit (FFU) is a type of motorized air filtering equipment. It is used to supply purified air to cleanrooms, laboratories, medical facilities or microenvironments by removing harmful airborne particles from recirculating air. The units are installed within the system's ceiling or floor grid. Large cleanrooms require a proportionally large number of FFUs, which in some cases may range from several hundred to several thousand. Units often contain their own pre-filter, HEPA filter and internally controllable fan air distribution.

Dry decontamination is a method of removing contaminants without the need to use water or other liquids. Decontamination is an essential duty of hazmat responders as it protects victims from harmful reactions to the contaminants.

A sticky mat, also called a tacky mat or cleanroom mat, is a mat with an adhesive surface that is placed at the entrances or exits to certain workplaces to remove contaminants from the bottoms of footwear and wheeled carts such as hand trucks. They are an example of an engineering control within the hierarchy of hazard controls.

Hazmat diving is underwater diving in a known hazardous materials environment. The environment may be contaminated by hazardous materials, the diving medium may be inherently a hazardous material, or the environment in which the diving medium is situated may include hazardous materials with a significant risk of exposure to these materials to members of the diving team. Special precautions, equipment and procedures are associated with hazmat diving so that the risk can be reduced to an acceptable level.