Titanium is a chemical element; it has symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in sea water, aqua regia, and chlorine.

Duralumin is a trade name for one of the earliest types of age-hardenable aluminium–copper alloys. The term is a combination of Dürener and aluminium. Its use as a trade name is obsolete. Today the term mainly refers to aluminium-copper alloys, designated as the 2000 series by the international alloy designation system (IADS), as with 2014 and 2024 alloys used in airframe fabrication.

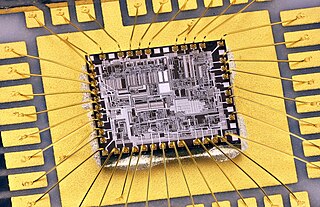

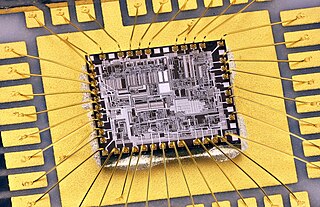

Wire bonding is a method of making interconnections between an integrated circuit (IC) or other semiconductor device and its packaging during semiconductor device fabrication. Wire bonding can also be used to connect an IC to other electronics or to connect from one printed circuit board (PCB) to another, although these are less common. Wire bonding is generally considered the most cost-effective and flexible interconnect technology and is used to assemble the vast majority of semiconductor packages. Wire bonding can be used at frequencies above 100 GHz.

Aluminium–silicon alloys or Silumin is a general name for a group of lightweight, high-strength aluminium alloys based on an aluminum–silicon system (AlSi) that consist predominantly of aluminum - with silicon as the quantitatively most important alloying element. Pure AlSi alloys cannot be hardened, the commonly used alloys AlSiCu and AlSiMg can be hardened. The hardening mechanism corresponds to that of AlCu and AlMgSi.

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

A cermet is a composite material composed of ceramic and metal materials.

Ductile iron, also known as ductile cast iron, nodular cast iron, spheroidal graphite iron, spheroidal graphite cast iron and SG iron, is a type of graphite-rich cast iron discovered in 1943 by Keith Millis. While most varieties of cast iron are weak in tension and brittle, ductile iron has much more impact and fatigue resistance, due to its nodular graphite inclusions.

Titanium alloys are alloys that contain a mixture of titanium and other chemical elements. Such alloys have very high tensile strength and toughness. They are light in weight, have extraordinary corrosion resistance and the ability to withstand extreme temperatures. However, the high cost of both raw materials and processing limit their use to military applications, aircraft, spacecraft, bicycles, medical devices, jewelry, highly stressed components such as connecting rods on expensive sports cars and some premium sports equipment and consumer electronics.

Titanium aluminide, commonly gamma titanium, is an intermetallic chemical compound. It is lightweight and resistant to oxidation and heat, but has low ductility. The density of γ-TiAl is about 4.0 g/cm3. It finds use in several applications including aircraft, jet engines, sporting equipment and automobiles. The development of TiAl based alloys began circa 1970. The alloys have been used in these applications only since about 2000.

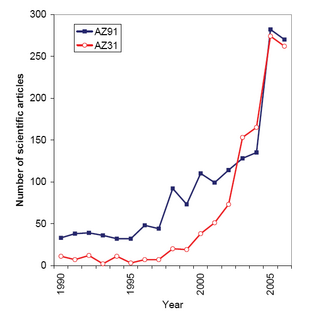

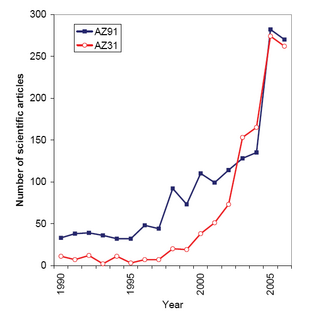

Magnesium alloys are mixtures of magnesium with other metals, often aluminium, zinc, manganese, silicon, copper, rare earths and zirconium. Magnesium alloys have a hexagonal lattice structure, which affects the fundamental properties of these alloys. Plastic deformation of the hexagonal lattice is more complicated than in cubic latticed metals like aluminium, copper and steel; therefore, magnesium alloys are typically used as cast alloys, but research of wrought alloys has been more extensive since 2003. Cast magnesium alloys are used for many components of modern automobiles and have been used in some high-performance vehicles; die-cast magnesium is also used for camera bodies and components in lenses.

An aluminium alloy (UK/IUPAC) or aluminum alloy is an alloy in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin, nickel and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to the low melting point, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.

6061 aluminium alloy is a precipitation-hardened aluminium alloy, containing magnesium and silicon as its major alloying elements. Originally called "Alloy 61S", it was developed in 1935. It has good mechanical properties, exhibits good weldability, and is very commonly extruded. It is one of the most common alloys of aluminium for general-purpose use.

7075 aluminium alloy (AA7075) is an aluminium alloy with zinc as the primary alloying element. It has excellent mechanical properties and exhibits good ductility, high strength, toughness, and good resistance to fatigue. It is more susceptible to embrittlement than many other aluminium alloys because of microsegregation, but has significantly better corrosion resistance than the alloys from the 2000 series. It is one of the most commonly used aluminium alloys for highly stressed structural applications and has been extensively used in aircraft structural parts.

In the automotive industry, alloy wheels are wheels that are made from an alloy of aluminium or magnesium. Alloys are mixtures of a metal and other elements. They generally provide greater strength over pure metals, which are usually much softer and more ductile. Alloys of aluminium or magnesium are typically lighter for the same strength, provide better heat conduction, and often produce improved cosmetic appearance over steel wheels. Although steel, the most common material used in wheel production, is an alloy of iron and carbon, the term "alloy wheel" is usually reserved for wheels made from nonferrous alloys.

Cobalt-chrome or cobalt-chromium (CoCr) is a metal alloy of cobalt and chromium. Cobalt-chrome has a very high specific strength and is commonly used in gas turbines, dental implants, and orthopedic implants.

2219 aluminium alloy is an alloy in the wrought aluminium-copper family. It can be heat-treated to produce tempers with higher strength but lower ductility. The aluminium-copper alloys have high strength, but are generally less corrosion resistant and harder to weld than other types of aluminium alloys. To compensate for the lower corrosion resistance, 2219 aluminium can be clad in a commercially pure alloy such as 1050 or painted. This alloy is commonly formed by both extrusion and forging, but is not used in casting.

5456 aluminium–magnesium alloy is an alloy in the wrought aluminium-magnesium family. While it is closely related to 5356 aluminium alloy, it is used in structural applications, like most other aluminium-magnesium alloys, and not as filler for welding. As a wrought alloy, it can be formed by rolling, extrusion, and forging, but not casting. It can be cold worked to produce tempers with a higher strength but a lower ductility. It is susceptible to exfoliation corrosion when held at temperatures above 65 °C (150 °F) for extended periods of time.

The 6463 aluminium alloy is an aluminium alloy in the wrought aluminium-magnesium-silicon family. It is related to 6063 aluminium alloy, but unlike 6063 it is generally not formed using any processes other than extrusion. It is commonly heat treated to produce tempers with a higher strength but lower ductility. Like 6063, it is often used in architectural applications.

Aluminium–copper alloys (AlCu) are aluminium alloys that consist largely of aluminium (Al) and traces of copper (Cu) as the main alloying elements. Important grades also contain additives of magnesium, iron, nickel and silicon, often manganese is also included to increase strength. The main area of application is aircraft construction. The alloys have medium to high strength and can be age hardened. They are both wrought alloy. Also available as cast alloy. Their susceptibility to corrosion and their poor weldability are disadvantageous.

Aluminium–magnesium–silicon alloys (AlMgSi) are aluminium alloys—alloys that are mainly made of aluminium—that contain both magnesium and silicon as the most important alloying elements in terms of quantity. Both together account for less than 2 percent by mass. The content of magnesium is greater than that of silicon, otherwise they belong to the aluminum–silicon–magnesium alloys (AlSiMg).