Related Research Articles

Logistics deals with the efficient forward and reverse flow of goods, services, and related information from the point of origin to the point of consumption according to the needs of customers. Logistics is a component of the supply chain management, where it that holds the supply chain together. The resources managed in logistics may include tangible goods such as materials, equipment, and supplies, as well as food and other consumable items.

Inventory or stock refers to the goods and materials that a business holds for the ultimate goal of resale, production or utilisation.

The point of sale (POS) or point of purchase (POP) is the time and place at which a retail transaction is completed. At the point of sale, the merchant calculates the amount owed by the customer, indicates that amount, may prepare an invoice for the customer, and indicates the options for the customer to make payment. It is also the point at which a customer makes a payment to the merchant in exchange for goods or after provision of a service. After receiving payment, the merchant may issue a receipt for the transaction, which is usually printed but can also be dispensed with or sent electronically.

A management information system (MIS) is an information system used for decision-making, and for the coordination, control, analysis, and visualization of information in an organization. The study of the management information systems involves people, processes and technology in an organizational context.

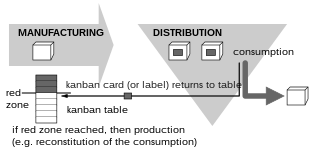

Kanban is a scheduling system for lean manufacturing. Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. The system takes its name from the cards that track production within a factory. Kanban is also known as the Toyota nameplate system in the automotive industry.

Cross-docking is a practice in logistics of unloading materials from a manufacturer or mode of transportation directly to the customer or another mode of transportation, with little or no storage in between. This may be done to change the type of conveyance, to sort material intended for different destinations, or to combine material from different origins into transport vehicles with the same or similar destinations.

Online shopping is a form of electronic commerce which allows consumers to directly buy goods or services from a seller over the Internet using a web browser or a mobile app. Consumers find a product of interest by visiting the website of the retailer directly or by searching among alternative vendors using a shopping search engine, which displays the same product's availability and pricing at different e-retailers. As of 2020, customers can shop online using a range of different computers and devices, including desktop computers, laptops, tablet computers and smartphones.

The beer distribution game is an educational game that is used to experience typical coordination problems of a supply chain process. It reflects a role-play simulation where several participants play with each other. The game represents a supply chain with a non-coordinated process where problems arise due to lack of information sharing. This game outlines the importance of information sharing, supply chain management and collaboration throughout a supply chain process. Due to lack of information, suppliers, manufacturers, sales people and customers often have an incomplete understanding of what the real demand of an order is. The most interesting part of the game is that each group has no control over another part of the supply chain. Therefore, each group has only significant control over their own part of the supply chain. Each group can highly influence the entire supply chain by ordering too much or too little which can lead to a bullwhip effect. Therefore, the order taking of a group also highly depends on decisions of the other groups.

Distribution software refers to software which manages everything from order processing and inventory control to accounting, purchasing and customer service, supply chain management, sales, customer relationship management, and finance management.

QuickBooks is an accounting software package developed and marketed by Intuit. First introduced in 1983, QuickBooks products are geared mainly toward small and medium-sized businesses and offer on-premises accounting applications as well as cloud-based versions that accept business payments, manage and pay bills, and payroll functions.

Planograms, also known as plano-grams, plan-o-grams, schematics and POGs, are visual representations of a store's products or services on display. They are considered a tool for visual merchandising. According to the Merriam-Webster Dictionary, a planogram is "a schematic drawing or plan for displaying merchandise in a store so as to maximize sales." The effectiveness of the planogram can be measured by the sales volume generated from the specific area being diagrammed.

Inventory control or stock control can be broadly defined as "the activity of checking a shop's stock". It is the process of ensuring that the right amount of supply is available within a business. However, a more focused definition takes into account the more science-based, methodical practice of not only verifying a business's inventory but also maximising the amount of profit from the least amount of inventory investment without affecting customer satisfaction. Other facets of inventory control include forecasting future demand, supply chain management, production control, financial flexibility, purchasing data, loss prevention and turnover, and customer satisfaction.

Supply-chain optimization (SCO) aims to ensure the optimal operation of a manufacturing and distribution of supply chain. This includes the optimal placement of inventory within the supply chain, minimizing operating costs including manufacturing costs, transportation costs, and distribution costs. Optimization often involves the application of mathematical modelling techniques using computer software. It is often considered to be part of supply chain engineering, although the latter is mainly focused on mathematical modelling approaches, whereas supply chain optimization can also be undertaken using qualitative, management based approaches.

Infor Nexus is an independent business unit of Infor LLC offering a multienterprise supply chain network. The on-demand global supply chain management platform and integrated applications are used worldwide by businesses to manage global direct procurement, supplier networks, global logistics and global trade processes. Founded in 1998 in Oakland, California, it merged with TradeCard in 2013, and in September 2015, GT Nexus was acquired by Infor. Today, Infor Nexus is a business unit of Infor.

Field inventory management commonly known as inventory management is the function of understanding the stock mix of a company and the different demands on that stock. The demands are influenced by both external and internal factors and are balanced by the creation of purchase order requests to keep supplies at a reasonable or prescribed level. Inventory management is important for every other business enterprise.

Supply-chain-management software (SCMS) is the software tools or modules used in executing supply chain transactions, managing supplier relationships and controlling associated business processes. Supply chain management maximizes the efficiency of business activities that include planning and management of the entire supply chain. It helps businesses in product development, sourcing, production, and logistics by automating operations. In this way, it increases the physical flow of business as well as informative flow. The entire business benefits with higher performance, greater cost-efficiency, and thus increased supply chain efficiency.

In a supply chain, a vendor, supplier, provider or a seller, is an enterprise that contributes goods or services. Generally, a supply chain vendor manufactures inventory/stock items and sells them to the next link in the chain. Today, these terms refer to a supplier of any goods or service.

Openbravo is a Spanish cloud-based software provider specializing in retail and restaurants; formerly known as a horizontal open-source ERP software vendor for different industries. The head office of Openbravo is located in Pamplona, Spain. Openbravo also has offices in Barcelona and Lille. The company's main product is Openbravo Commerce Cloud, a cloud-based omnichannel platform.

Petrolsoft Corporation (1989–2000) was a supply chain management software company with a focus on the petroleum industry. Petrolsoft Corporation was founded at Stanford University in 1989 by Bill Miller and David Gamboa as Petrolsoft Software Group. It was later incorporated in 1992. Petrolsoft introduced demand-driven inventory management to the petroleum industry.

Inventory management software is a software system for tracking inventory levels, orders, sales and deliveries. It can also be used in the manufacturing industry to create a work order, bill of materials and other production-related documents. Companies use inventory management software to avoid product overstock and outages. It is a tool for organizing inventory data that before was generally stored in hard-copy form or in spreadsheets.

References

- ↑ "What is Back Office Application? – Definition from Techopedia". Techopedia.com. Retrieved 2015-12-06.

- ↑ "back office application Definition from PC Magazine Encyclopedia". www.pcmag.com. Retrieved 2015-12-06.

- 1 2 "The Best Back Office Software for Running Your Business". Inc.com. 2011-08-17. Retrieved 2015-12-06.

- ↑ "Inventory Turnover Definition | Investopedia". Investopedia. Retrieved 2015-12-07.

- ↑ "Leverage Inventory Management for Superior Performance" (PDF). Petrosoft. Retrieved December 7, 2015.

- ↑ Smith, Stephen A.; Agrawal, Narendra (2000-02-01). "Management of Multi-Item Retail Inventory Systems with Demand Substitution". Operations Research. 48 (1): 50–64. doi:10.1287/opre.48.1.50.12443. ISSN 0030-364X.

- ↑ Caro, Felipe; Gallien, Jérémie (2009-08-12). "Inventory Management of a Fast-Fashion Retail Network" (PDF). Operations Research. 58 (2): 257–273. doi:10.1287/opre.1090.0698. hdl: 1721.1/39810 . ISSN 0030-364X.

- ↑ Cachon, Gérard P.; Fisher, Marshall (2000-08-01). "Supply Chain Inventory Management and the Value of Shared Information". Management Science. 46 (8): 1032–1048. CiteSeerX 10.1.1.128.6304 . doi:10.1287/mnsc.46.8.1032.12029. ISSN 0025-1909.

- ↑ DeHoratius, Nicole; Mersereau, Adam J.; Schrage, Linus (2008-03-11). "Retail Inventory Management When Records Are Inaccurate". Manufacturing & Service Operations Management. 10 (2): 257–277. CiteSeerX 10.1.1.135.2297 . doi:10.1287/msom.1070.0203. ISSN 1523-4614.