A bale wrapper is a farm implement for wrapping bales in plastic, for them to turn into silage. [1]

Contents

Bale wrappers come in three main forms - turntable type, satellite type and in-line type.

A bale wrapper is a farm implement for wrapping bales in plastic, for them to turn into silage. [1]

Bale wrappers come in three main forms - turntable type, satellite type and in-line type.

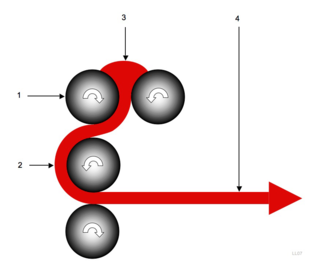

A satellite bale wrapper usually consists of hydraulic driven bale supporting rollers and a hydraulic driven rotating satellite arm which carries the plastic film roll and dispensing unit. The rotation of the support rollers and the satellite arm are synchronized so that an even cover of plastic film is applied to the bale as the wrapping process takes place. High speed satellite wrappers have two rotating satellite arms which effectively halves the time taken to wrap a bale.

The wrapper has a loading arm, much like a bale handler, at the side, that scoops up a bale and places it on the wrapping table. The wrapping table usually consists of two rollers, and four belts which slowly spin the bales while the table itself revolves. As the bale turns, plastic film is pulled through the dispensing unit and wrapped tightly on the bale. When the table has revolved at least 16 times, the bale can be ejected. This is done by a hydraulic ram which tilts the wrapping table, so that the bale can be tipped off. The film is cut and then tied to the wrapper for the next bale. All this is controlled via a computer inside the cab of the tractor.

Best suited for high volume producers the in-line wrapper places bales in neat rows along fields and yards. The bale is placed on the wrappers saddle or table and is driven forward by a push ram allowing the producers to consecutively wrap each bale into one long tube. This also allows for producers to save time and money in the process, by eliminating the need for an extra working hand and save on plastic wrap costs.

Hay is grass, legumes, or other herbaceous plants that have been cut and dried to be stored for use as animal fodder, either for large grazing animals raised as livestock, such as cattle, horses, goats, and sheep, or for smaller domesticated animals such as rabbits and guinea pigs. Pigs can eat hay, but do not digest it as efficiently as herbivores do.

Silage is a type of fodder made from green foliage crops which have been preserved by fermentation to the point of acidification. It can be fed to cattle, sheep, and other such ruminants. The fermentation and storage process is called ensilage, ensiling, or silaging. Silage is usually made from grass crops, including maize, sorghum, or other cereals, using the entire green plant.

A compactor is a machine or mechanism used to reduce the size of material such as waste material or bio mass through compaction. A trash compactor is often used by business and public places like hospitals to reduce the volume of trash they produce. A baler-wrapper compactor is often used for making compact and wrapped bales in order to improve logistics.

A baler or hay baler is a piece of farm machinery used to compress a cut and raked crop into compact bales that are easy to handle, transport, and store. Often, bales are configured to dry and preserve some intrinsic value of the plants bundled. Different types of balers are commonly used, each producing a different type of bale – rectangular or cylindrical, of various sizes, bound with twine, strapping, netting, or wire.

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive and shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process.

A dynamometer or "dyno" for short, is a device for simultaneously measuring the torque and rotational speed (RPM) of an engine, motor or other rotating prime mover so that its instantaneous power may be calculated, and usually displayed by the dynamometer itself as kW or bhp.

Shrink wrap, also shrink film, is a material made up of polymer plastic film. When heat is applied, it shrinks tightly over whatever it is covering. Heat can be applied with a handheld heat gun, or the product and film can pass through a heat tunnel on a conveyor.

A calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. Calender rolls are also used to form some types of plastic films and to apply coatings. Some calender rolls are heated or cooled as needed. Calenders are sometimes misspelled calendars.

A punch press is a type of machine press used to cut holes in material. It can be small and manually operated and hold one simple die set, or be very large, CNC operated, with a multi-station turret and hold a much larger and complex die set.

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the steam-generating furnaces of coal power plants.

Roller furling is a method of furling a yacht's staysail by rolling the sail around a stay. Roller furling is typically used for foresails such as jibs or genoas.

A hydraulic motor is a mechanical actuator that converts hydraulic pressure and flow into torque and angular displacement (rotation). The hydraulic motor is the rotary counterpart of the hydraulic cylinder as a linear actuator. Most broadly, the category of devices called hydraulic motors has sometimes included those that run on hydropower but in today's terminology the name usually refers more specifically to motors that use hydraulic fluid as part of closed hydraulic circuits in modern hydraulic machinery.

Stretch wrap or stretch film, sometimes known as pallet wrap, is a highly stretchable plastic film that is wrapped around items. The elastic recovery keeps the items tightly bound. In contrast, shrink wrap is applied loosely around an item and shrinks tightly with heat. While it is similar to plastic food wrap, it is not usually made of material rated as safe for food contact.

A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transport of heavy or bulky materials. Conveyor systems allow quick and efficient transport for a wide variety of materials, which make them very popular in the material handling and packaging industries. They also have popular consumer applications, as they are often found in supermarkets and airports, constituting the final leg of item/ bag delivery to customers. Many kinds of conveying systems are available and are used according to the various needs of different industries. There are chain conveyors as well. Chain conveyors consist of enclosed tracks, I-Beam, towline, power & free, and hand pushed trolleys.

A screw press is a type of machine press in which the ram is driven up and down by a screw. The screw shaft can be driven by a handle or a wheel. It works by using a coarse screw to convert the rotation of the handle or drive-wheel into a small downward movement of greater force. The overhead handle usually incorporates balls as flyweights. The weights helps to maintain the momentum and thrust of the tool to make it easier to operate.

A log splitter is a piece of machinery or equipment used for splitting firewood from softwood or hardwood logs that have been pre-cut into sections (rounds), usually by chainsaw or on a saw bench. Many log splitters consist of a hydraulic pump or electric motor which then powers a hydraulic or electrical rod and piston assembly. Generally, these are often rated by the tons of force they can generate. The higher the force rating, the greater the thickness or length of the rounds that can be split. The log splitter consists of all four major hydraulic components.

Turntable stretch wrappers are a type of automatic and semi-automatic stretch wrapping system. A load is placed on a turntable, which rotates relative to the film roll, which is housed in a carriage attached to a vertical "mast" on which it may move up and down.

An orbital stretch wrapper is a means of applying stretchable plastic film to a load, consisting of a roll of stretch wrap supported on a vertical rotating ring and a means of passing a load through the ring's eye horizontally. Several designs are available.

A Drum handler is a piece of mechanical equipment that is used to securely grip, lift and transport cylindrical modules such as steel drums, barrels, plastic drums and fiber drums. It has spring-loaded metal arms to create a tight and secure grip. This equipment is commonly used in chemical and petroleum industries, as well as industries that require shipping and storing of cylindrical modules.

A rotary union is a union that allows for rotation of the united parts. It is thus a device that provides a seal between a stationary supply passage and a rotating part to permit the flow of a fluid into and/or out of the rotating part. Fluids typically used with rotary joints and rotating unions include various heat transfer media and fluid power media such as steam, water, thermal oil, hydraulic fluid, and coolants. A rotary union is sometimes referred to as a rotating union, rotary valve, swivel union,rotorseal, rotary couplings, rotary joint, rotating joints, hydraulic coupling, pneumatic rotary union, through bore rotary union, air rotary union, electrical rotary union, or vacuum rotary union

![]() Media related to Bale wrappers at Wikimedia Commons

Media related to Bale wrappers at Wikimedia Commons