Bead weaving is a set of techniques for weaving sheets and objects of seed beads. Threads are strung through and/or around the beads to hold them together. It can be done either on a loom or using one of a number of off-loom stitches.

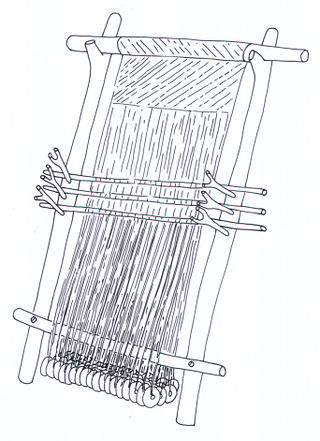

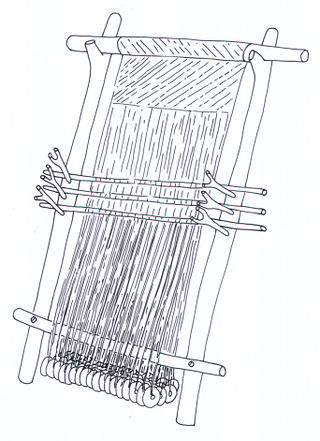

A loom is a device used to weave cloth and tapestry. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. The precise shape of the loom and its mechanics may vary, but the basic function is the same.

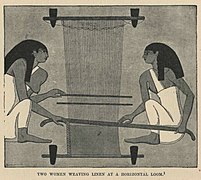

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft, woof, or filling. The method in which these threads are interwoven affects the characteristics of the cloth. Cloth is usually woven on a loom, a device that holds the warp threads in place while filling threads are woven through them. A fabric band that meets this definition of cloth can also be made using other methods, including tablet weaving, back strap loom, or other techniques that can be done without looms.

A power loom is a mechanized loom, and was one of the key developments in the industrialization of weaving during the early Industrial Revolution. The first power loom was designed and patented in 1785 by Edmund Cartwright. It was refined over the next 47 years until a design by the Howard and Bullough company made the operation completely automatic. This device was designed in 1834 by James Bullough and William Kenworthy, and was named the Lancashire loom.

Tablet weaving is a weaving technique where tablets or cards are used to create the shed through which the weft is passed. As the materials and tools are relatively cheap and easy to obtain, tablet weaving is popular with hobbyist weavers. Most tablet weavers produce narrow work such as belts, straps, or garment trims.

The flying shuttle is a type of weaving shuttle. It was a pivotal advancement in the mechanisation of weaving during the initial stages of the Industrial Revolution, and facilitated the weaving of considerably broader fabrics, enabling the production of wider textiles. Moreover, its mechanical implementation paved the way for the introduction of automatic machine looms.

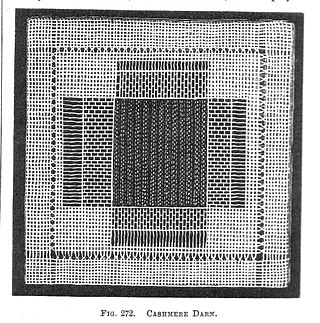

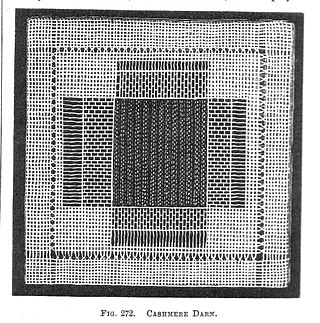

Darning is a sewing technique for repairing holes or worn areas in fabric or knitting using needle and thread alone. It is often done by hand, but using a sewing machine is also possible. Hand darning employs the darning stitch, a simple running stitch in which the thread is "woven" in rows along the grain of the fabric, with the stitcher reversing direction at the end of each row, and then filling in the framework thus created, as if weaving. Darning is a traditional method for repairing fabric damage or holes that do not run along a seam, and where patching is impractical or would create discomfort for the wearer, such as on the heel of a sock.

A shuttle is a tool designed to neatly and compactly store a holder that carries the thread of the weft yarn while weaving with a loom. Shuttles are thrown or passed back and forth through the shed, between the yarn threads of the warp in order to weave in the weft.

Pile weave is a form of textile created by weaving. This type of fabric is characterized by a pile—a looped or tufted surface that extends above the initial foundation, or 'ground' weave. The pile is formed by supplemental yarn running in the direction of the length of the fabric or the width of the fabric. Pile weaves include velvet and corduroy fabrics and machine-woven Berber carpets.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fiber from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, with color and patterns, which turns it into cloth. The machine used for weaving is the loom. For decoration, the process of coloring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

In weaving, the shed is the temporary separation between upper and lower warp yarns through which the weft is woven. The shed is created to make it easy to interlace the weft into the warp and thus create woven fabric. Most types of looms have some sort of device which separates some of the warp threads from the others. This separation is called the shed, and allows for a shuttle carrying the weft thread to move through the shed perpendicular to the warp threads. Which threads are raised and which are lowered are changed after each pass of the shuttle.

Band weaving refers to the hand production of narrow woven fabric. This fabric may be called tape, band, inkle, strap, belt, back strap, trim, and more. It can be accomplished on a variety of types of looms, including inkle, band, tape, backstrap, and rigid heddle looms. Hole and slot heddles are also designed to weave bands. Depending on which loom is used, the material could be warp-faced or a balanced weave.

A heddle or heald is an integral part of a loom. Each thread in the warp passes through a heddle, which is used to separate the warp threads for the passage of the weft. The typical heddle is made of cord or wire and is suspended on a shaft of a loom. Each heddle has an eye in the center where the warp is threaded through. As there is one heddle for each thread of the warp, there can be near a thousand heddles used for fine or wide warps. A handwoven tea-towel will generally have between 300 and 400 warp threads and thus use that many heddles.

A weavers' cottage was a type of house used by weavers for cloth production in the putting-out system sometimes known as the domestic system.

Textile manufacturing is one of the oldest human activities. The oldest known textiles date back to about 5000 B.C. In order to make textiles, the first requirement is a source of fibre from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving to create cloth. The machine used for weaving is the loom. Cloth is finished by what are described as wet process to become fabric. The fabric may be dyed, printed or decorated by embroidering with coloured yarns.

The Roberts loom was a cast-iron power loom introduced by Richard Roberts in 1830. It was the first loom that was more viable than a hand loom and was easily adjustable and reliable, which led to its widespread use in the Lancashire cotton industry.

A reed is part of a weaving loom, and resembles a comb or a frame with many vertical slits. It is used to separate and space the warp threads, to guide the shuttle's motion across the loom, and to push the weft threads into place. In most floor looms with, the reed is securely held by the beater. Floor looms and mechanized looms both use a beater with a reed, whereas Inkle weaving and tablet weaving do not use reeds.

The warp-weighted loom is a simple and ancient form of loom in which the warp yarns hang freely from a bar, which is supported by upright poles which can be placed at a convenient slant against a wall. Bundles of warp threads are tied to hanging weights called loom weights which keep the threads taut.

Waffle fabric, also known as honeycomb fabric, has raised threads that form small rectangles. It can be made by either weaving or knitting. Waffle weave is a further exploitation of plain weave and twill weave which produces a three-dimensional effect. The combination of warp and weft floats creates the structure. It is woven partly on tabby areas surrounded by ridges of long floats. The weave consists of warp and weft floats arranged around a plain weave center. The warp and weft threads are interlaced and floating in a way that creates small square ridges and hollows in the fabric in a regular pattern.

A temple is an adjustable stretcher used on a loom to maintain the width and improve the edges of the woven fabric.